304L stainless steel pipe is a non-magnetic stainless steel pipe with a low-carbon (C ≤ 0.03%) version based on austenitic 18-8 alloy (approximately 18-20% Cr, 8-12% Ni). Its low carbon content significantly enhances the resistance to intergranular corrosion after welding, while maintaining excellent mechanical and processing properties similar to those of 304. It is widely used in fields such as chemical engineering, petroleum and natural gas, food processing, heat exchangers and architectural decoration.

304L exhibits excellent corrosion resistance in most oxidizing and reducing media, especially after welding, when the low carbon content reduces carbide precipitation, thereby lowering the risk of intergranular corrosion. It has excellent corrosion resistance in seawater, atmosphere and food processing environments. Welded structures can be safely used at temperatures below 800 °F (about 427 °C) without the need for additional solution treatment.

Standards and Specifications

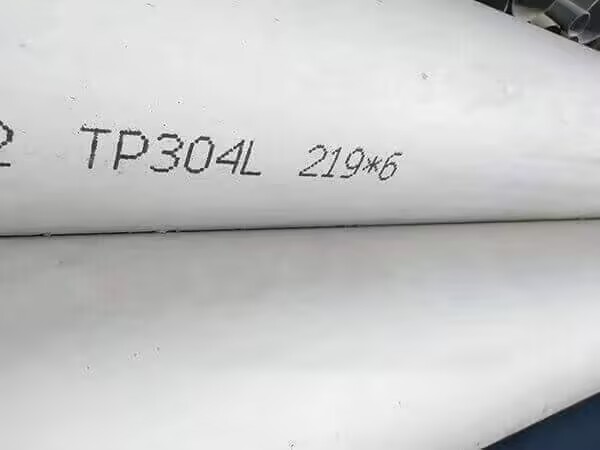

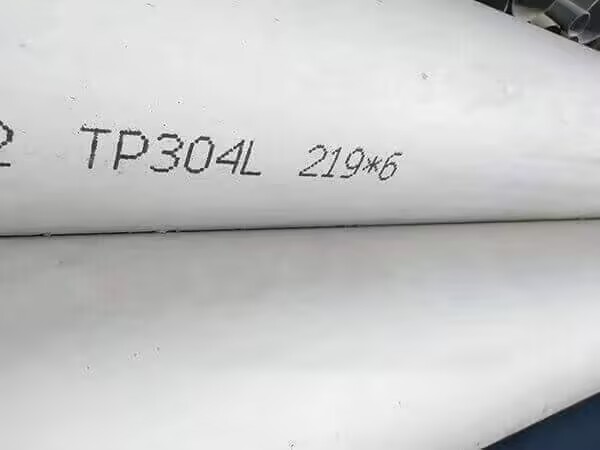

ASTM A312/A213: Common standards for seamless and welded austenitic stainless steel tubes, covering size ranges from 1/8" to 30" (SCH 10S to SCH 80S), including TP304/304L grades.

Nominal diameter (NB) 6 to 1200, outer diameter 1/8" to 12" NPS, wall thickness 0.6-12.7 mm, length available as single, double random or cut length

Manufacturing and Processing

304L pipes can be produced through processes such as seamless extrusion or resistance welding (ERW).

Seamless pipes are more reliable under high pressure and high temperature working conditions. Welded pipes have more advantages in terms of cost and dimensional flexibility.

Due to its excellent cold working plasticity, 304L can undergo cold rolling, cold drawing, pipe bending and precision forming. After forming, annealing treatment is required to restore its corrosion resistance.

Common welding methods: TIG (argon arc welding) or MIG/SAW (Gas fusion Electrode welding/submerged arc welding) are commonly used. For food-grade and high-purity pipelines, self-melting welding is preferred for butt welding.

When welding, it is recommended to use low-carbon or chromium-nickel matching welding wires (such as ER308L) as filler metals to maintain consistent chemical composition of the base material and reduce the precipitation of carbides in the heat-affected zone.

Application field

Chemical and petrochemical industries: Transporting corrosive media such as concentrated acids and alkalis.

Food and pharmaceuticals: Piping systems and equipment that meet hygiene standards.

Ocean and Ships: Seawater pipelines, ship piping.

Petroleum and natural gas: Medium and low pressure pipelines, heat exchangers.

Architectural decoration: handrails, rainwater pipes, curtain wall decorative pipes.

The difference from 304 stainless steel pipes

Carbon content: up to 0.08 % for 304 and up to 0.03 % for 304L, with a difference of 0.05 %, is the core difference between the two.

Chromium (Cr) and nickel (Ni) : Both contain 18-20 % Cr and 8-11 % Ni, and their chemical compositions are basically the same.

Other elements (Mn, Si, P, S) : The differences within their respective upper limit ranges are extremely small and can be regarded as equivalent.

In terms of mechanical properties

Yield strength (0.2 %Proof) : 304 ≥ 205 MPa, 304L ≥ 170-200 MPa, 304L is slightly lower than 304.

Tensile strength: 304 ≥ 515 MPa, 304L ≥ 485 MPa, the difference is mainly due to the different solid solution strengthening effects caused by carbon content.

Elongation: Both have good ductility, with an elongation of more than 40 %, and the difference is not obvious.