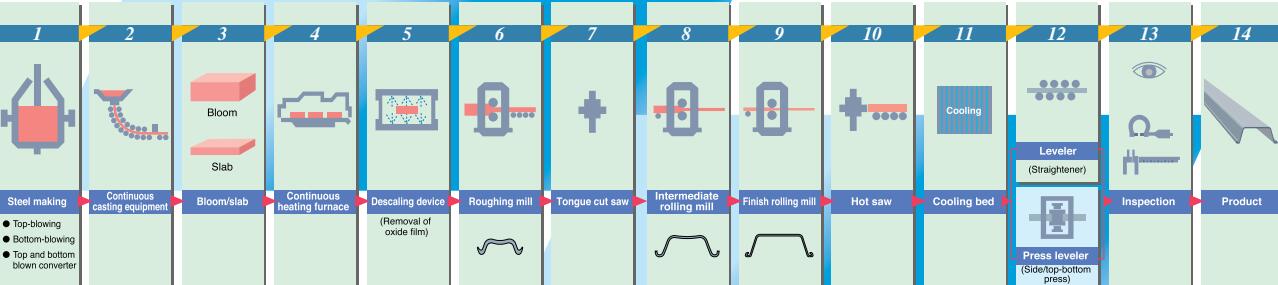

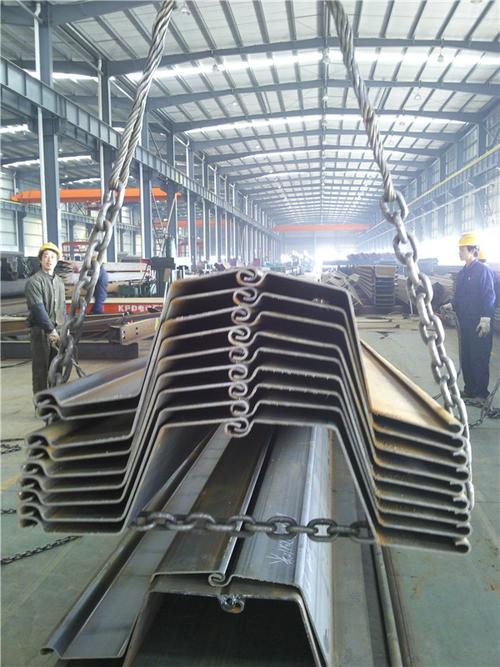

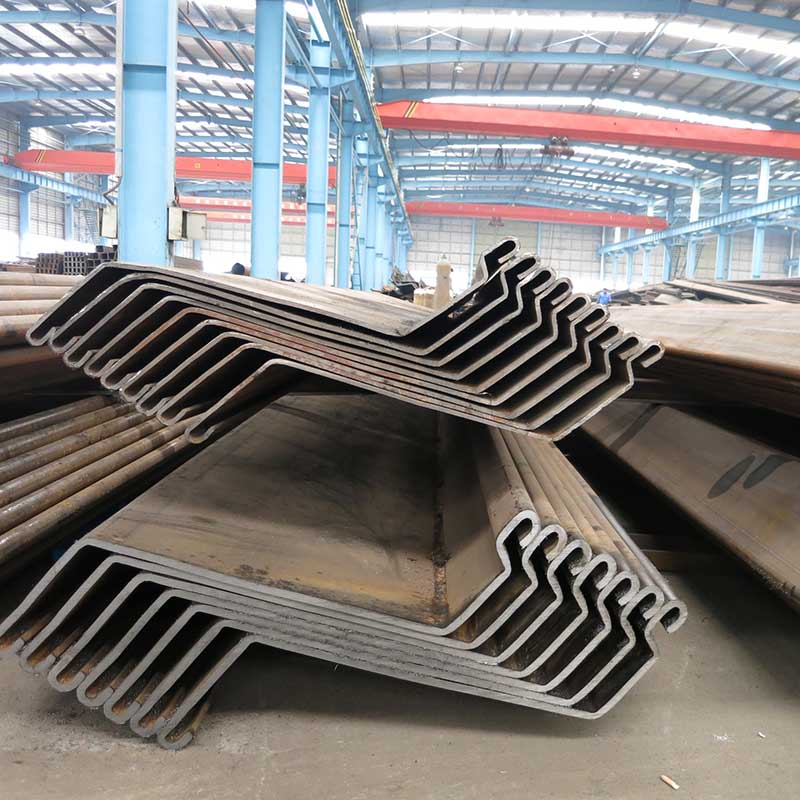

Z-shaped Steel Sheet Pile are produced in zigzag form and are usually driven in crimped or welded doubles. Z type sheet piles are more widely used than U-type piles in port construction and deep foundations because Z type sheets can have greater modulus and can be used as intermediate piles in tubular & HZ combination walls.

1. Flexible design, high section modulus, and mass ratio;

2. Higher moment of inertia increases the stiffness of sheet pile wall and reduces the displacement deformation;

3. Large width, effectively saving the time of lifting and piling;

4. Thickening treatment is carried out in the parts with serious corrosion, and the corrosion resistance is excellent.

6. The weight per square meter of a Z sheet pile is always less than that of a U sheet pile for a similar section modulus.

7. It can be used as an infill pile together with steel pipes and H-beams, and is usually used to obtain a very high modulus.

The steel sheet pile is very wide, in the permanent structure of the building, can be used for wharf, unloading yard, embankment revetment, wall, retaining wall, breakwater, diversion embankment, dock, gate, etc.; In temporary structures, can be used to seal the mountain, temporary shore expansion, cut-off, bridge cofferdam, large pipeline laying temporary ditch excavation retaining, water, sand, and so on; In flood fighting, it can be used for flood control, collapse prevention, sand and so on.