Sizes

1/2”-60” NPS (DN15-DN3000)

Thickness SCH10,STD,SCH40,SCH60,XS, SCH80,SCH120,SCH160,XXS

Materials:

ASTM A105 – Forged Carbon Steel

ASTM A181 – Forged Carbon Steel for General Purpose

ASTM A182 – Forged Alloy Steel and Stainless Steel

ASTM A350 – Forged Alloy Steel for low temperature services

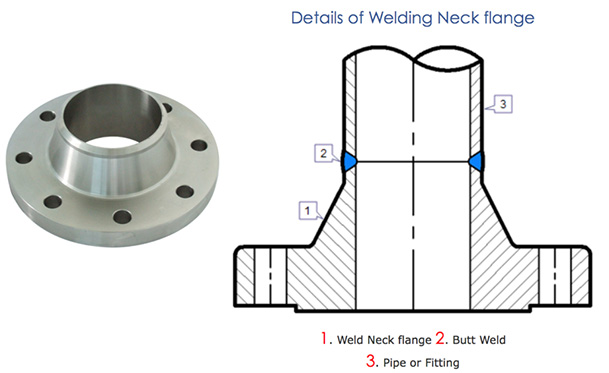

Weld Neck Flange

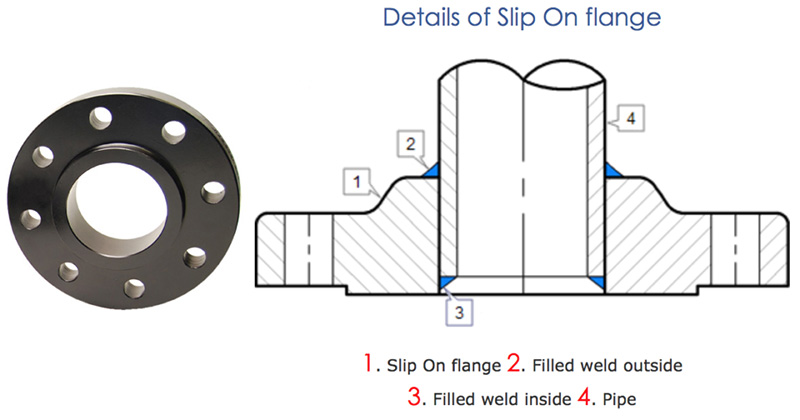

Slip-On Flanges

Specification of Slip-On Flanges

DN15-DN2000

Slip-On Flange Pressure Grade

PN series: PN2.5Mpa~PN40Mpa;

Class series: Class150~Class1500;

Slip-On Flange Standard

National standard of the People’s Republic of China: GB/T 9116-2010 Steel Slip-On Flange;

Chemical industry standards of the People’s Republic of China: PN series (European system) in HG/T20592~20635-2009, Class series (American system) in HG/T20592~20635-2009;

Slip-On Flange Materials

Carbon Steel Flange: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65 ,F70;

Stainless Steel Flange: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel Flange: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;

Sealing Surface Types For Slip-On Flanges

RF (Raised Face);

FF (Flat Face);

MFM (Male-and-Female Face);

F (Female Face);

M (Male Face);

TG (Tongue and Groove Face);

Among them, the uneven surface (MFM) is a matching use;

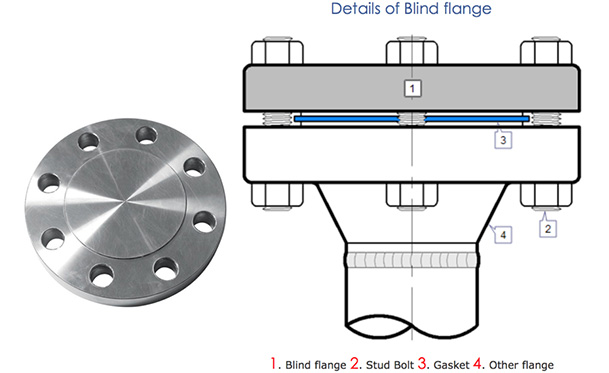

Blind Flanges

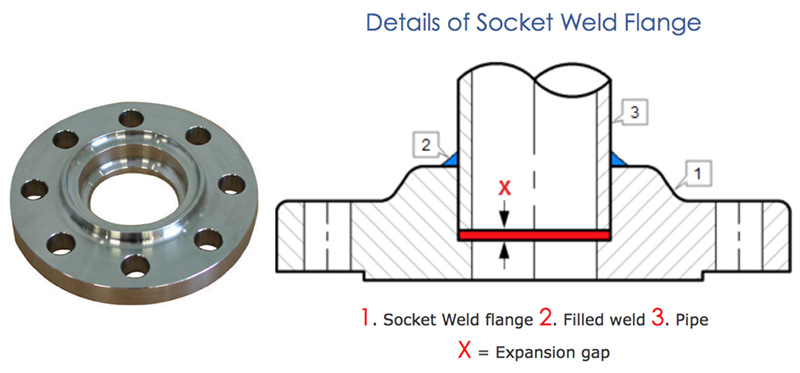

Socket Welded Flange

Socket Welded Flange Face Types

SW Flange: DN15-DN80

Outer Diameters: 1/2 inch to 48 inch, up to 1500#

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

Socket Weld Flange Pressure Grade

PN≤26.0MPa

SW Flange Standards

ANSI B16.5

HG20619-1997

GB/T9117.1-2000—GB/T9117.4-200

HG20597-1997

Socket Weld Flange Materials

Carbon Steel Flange: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65 ,F70;

Stainless Steel Flange: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel Flange: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;

Socket Welded Flange Face Types

RF (Raised Face)

M&F (Male-and-Female Face)

RTJ (Ring-Type Joint)

T&G (Tongue and Groove Face)

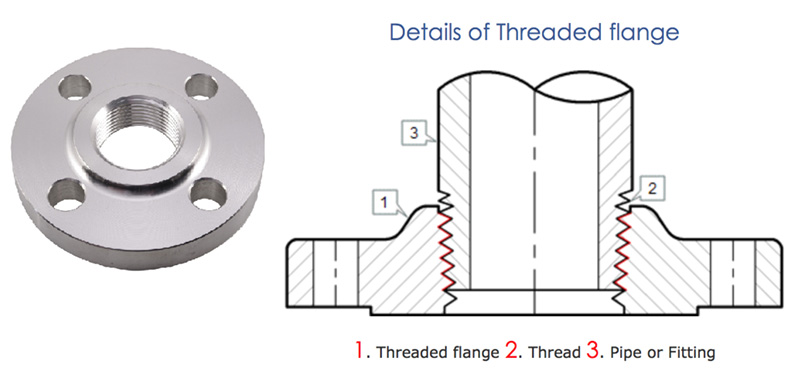

Threaded Flanges

Specification of Threaded Flanges

DN15-DN600

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

Threaded Flange Materials

Carbon Steel Flange: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65 ,F70;

Stainless Steel Flange: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel Flange: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;

Threaded Pipe Flange Standards

ANSI B16.5

Threaded Flange Pressure Grade

ANSI class 150, 300, 400, 600, 900, 1500, 2500

Sealing Surface Types For Threaded Pipe Flanges

RF (Raised Face);

FF (Flat Face);

M&F (Male-and-Female Face);

RTJ (Ring-Type Joint)

F (Female Face);

M (Male Face);

T&G (Tongue and Groove Face);

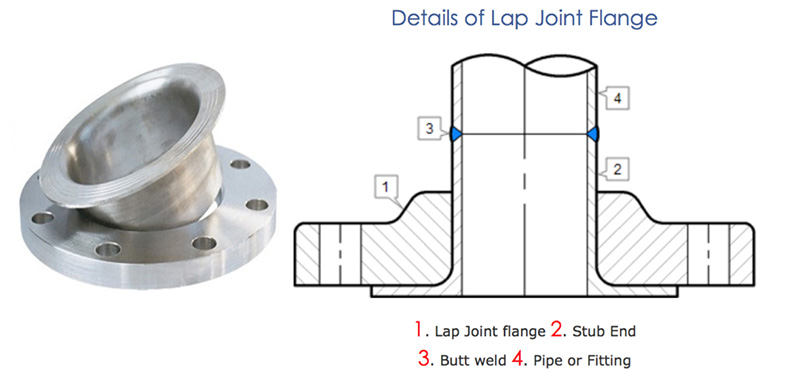

Lap Joint Flanges

Specification of Lap Joint Flanges

LJ Forged Flange: DN15-DN600

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

Lap Joint Flange Pressure Grade

PN0.25MPa,PN0.6MPa,PN1.0MPa,PN1.6MPa,PN2.5MPa,PN4.0MPa;

Lap Joint Flange Standards

ANSI B16.5

Male Face Steel Butt Weld Ring Lap Joint Pipe Flange with Neck: GB/T 9118.1-2000;

Ring Lap Steel Joint Pipe Flange with Neck: GB/T 9118.2-2000;

Butt Welding Lap Joint Pipe Flange: HG 20599-1997;

Flat Welding Lap Joint Pipe Flange: HG 20600-1997;

Sealing Surface Types For Lap Joint Pipe Flanges

RF (Raised Face);

FF (Flat Face);

M&F (Male-and-Female Face);

RTJ (Ring-Type Joint)

F (Female Face);

M (Male Face);

T&G (Tongue and Groove Face);

Lap Joint Flange Materials

Carbon Steel Flange: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65 ,F70;

Stainless Steel Flange: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel Flange: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;

Differenet faceing on flange

Raised Face Flange (RF)

Flat Face Flange (FF)

Ring Type Joint (RTJ)

Tongue and Groove (T/G)

Usage of pipe flange

For pipe connection

Pipe flanges are used to connect a series of pipes for water system.

For connecting valve

Pipe flanges are used to connect valves to control the flow within a water system.

To conect pump

To integrate pump to power the flow of water in line.

A Pipe Flange is a raised ridge, lip or edge, whether external or internal, used to add strength; to facilitate connection/transmit contact forces with other objects; or to stabilize and guide the movement of a machine or its components. The term Pipe Flange is also used for a tool used to form Pipe Flanges. Pipe Flanges can also be plates or rings to form an edge at the end of the pipe when secured to the pipe. A blind Pipe Flange is a plate used to cover or close off the end of a pipe. A Pipe Flange joint is a connection of pipes in which the joints have Pipe Flanges and the parts are connected together by Pipe Flange bolts. While the word "Pipe Flange" often refers to the actual raised edge or lip of the fitting, many Pipe Flanged pipe fittings are themselves Pipe Flanges.

Pipe Flanges are used to connect special items such as pipes, valves, fittings and filters and pressure vessels. Cover plates can be attached to form blind Pipe Flanges. Pipe Flanges are connected by bolts, and sealing is usually done with gaskets or other methods. Mechanical devices to mitigate the effects of leaks, such as spray shields or specific spray Pipe Flanges, may be included. Industries that process flammable, volatile, toxic or corrosive substances require special protection at Pipe Flange connections. Pipe Flange guards can provide a higher level of protection for safety.