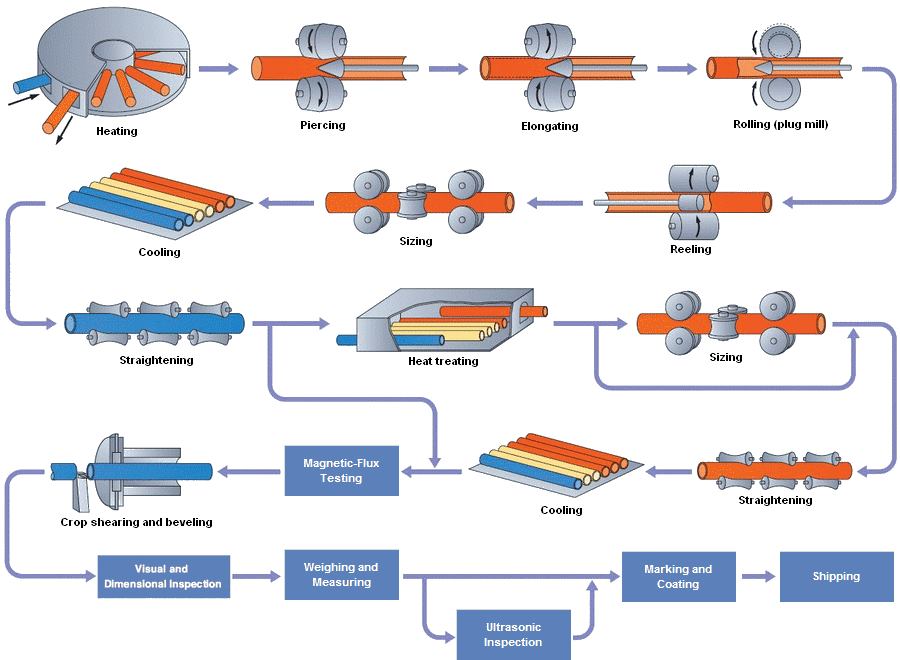

Production Process

Billet Preparation: High-quality carbon steel billets are heated to a high temperature.

Extrusion: The billet is extruded through a die to form a hollow shell.

Cold Drawing: The pipe is further processed through cold drawing to achieve precise dimensions and surface finish.

Heat Treatment: Normalizing or annealing is performed to enhance mechanical properties.

Inspection: The pipes undergo rigorous testing, including ultrasonic and hydrostatic tests, to ensure quality.

Applications

Oil and gas exploration and refining

Power generation (boiler and heat exchanger tubes)

High-pressure hydraulic systems

Structural and mechanical applications

Advantages

High Strength: No welded seams, making them stronger and more reliable for high-pressure applications.

Uniformity: Consistent wall thickness and smooth interior surface.

High-Temperature Resistance: Suitable for extreme temperature conditions.