Products: Drill Pipe, Heavy Weight Drill Pipe, Drill Collar

Size: 2-3/8"--6-5/8"

Standard: API 5DP

Grade: E75, X95, G105, S135, SS-105

Length: Range 1, Range 2 or 3

Upset of Drill Pipe

Internal-External Upset IEU

|

Mechanical properties of API drill pipe grades |

||||

|

Grade

|

Yield strength

|

Tensile strength

|

API

|

|

|

psi

N/mm2

min.

|

psi

N/mm2

max.

|

psi

N/mm2

min.

|

||

| E |

75 000

515

|

105 000

725

|

100 000

690

|

Spec. 5 DP

|

| X |

95 000

655

|

125 000

860

|

105 000

725

|

Spec. 5 DP

|

| G |

105 000

725

|

135 000

930

|

115 000

795

|

Spec. 5 DP

|

| S |

135 000

930

|

165 000

1 140

|

145 000

1 000

|

Spec. 5 DP

|

|

Mechanical properties of API tool joint grades |

||||

|

Yield strength

|

Yield strength

|

Tensile strength

|

Elongation

|

Box

|

|

psi

N/mm2

min.

|

psi

N/mm2

max

|

psi

N/mm2

min

|

in 2 inches

%

min

|

Hardness

Brinell

min

|

|

120 000

827

|

165 000

1138

|

140 000

965

|

13 | 285 |

|

Chemical composition requirements |

||||

|

Pipe body |

Phosphorus

max. %

|

Sulfur

max. %

|

||

|

Pipe body grade E

|

0.030

|

0.020

|

||

|

Pipe body grades X, G and S

|

0.020

|

0.015

|

||

|

Tool joint

|

0.020 |

0.015

|

||

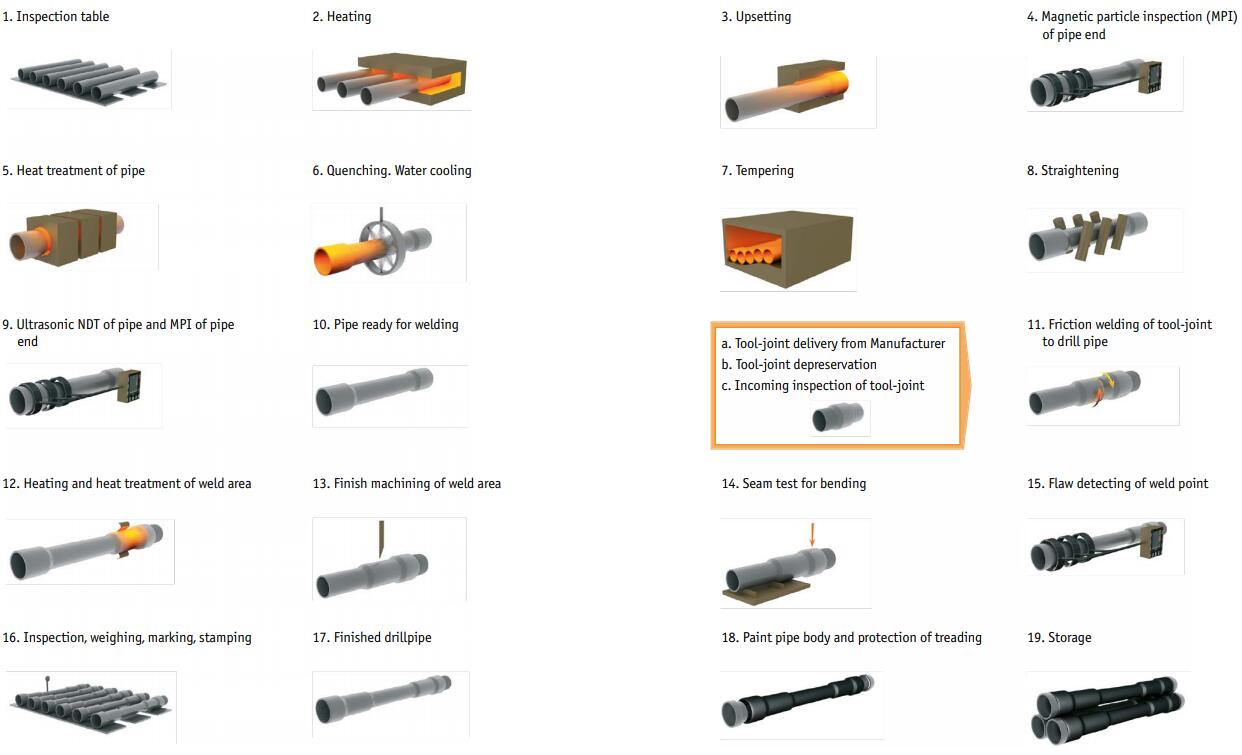

Details of manufacturing

Tool joints are inertia welded to the tubes with computer-monitored precision. Concentricity is carefully monitored and controlled, and the parameters of each weld are electronically recorded, and traceable to each joint.

After removal of weld flash, the weld area is austenitized, quenched, and tempered to achieve the required mechanical properties. Heat treat cycles for each weld are compared to specific parameters and recorded for traceability.

After all steps and machine marks are polished from the OD and ID area, hardness testing, ultrasonic testing, and wet magnetic particle inspections are used to verify the integrity of each weld zone.

Drill Pipe Dimensional Range and Performance Properties

Thedrill pipeis a steel pipe with threads at the end, which is used to connect the surface equipment of the drilling rig and the drilling and grinding equipment or the bottom hole device at the bottom of the drilling well. The purpose of the drill pipe is to transport the drilling mud to the drill bit and together with the drill bit to raise, lower or rotate the bottom hole device. Drill pipe must be able to withstand enormous internal and external pressure, twisting, bending and vibration. In the process of oil and gas extraction and refining, the drill pipe can be used many times.