Productos: Tubo de taladro, tubo de taladro pesado, cuello de taladro

Tamaño: 2-3/8 "-6-5/8"

Estándar: API 5DP

Grado: E75, X95, G105, S135, SS-105

Longitud: rango 1, rango 2 o 3

Malestar de la tubería de perforación

Interno-Malestar externo IEU

|

Propiedades mecánicas de los grados de tubería de perforación API |

||||

|

Grado

|

Fuerza de rendimiento

|

Resistencia a la tracción

|

API

|

|

|

PSI

N/mm2

Min.

|

PSI

N/mm2

Max.

|

PSI

N/mm2

Min.

|

||

| E |

75 000

515

|

105 000

725

|

100 000

690

|

Spec. 5 DP

|

| X |

95 000

655

|

125 000

860

|

105 000

725

|

Spec. 5 DP

|

| G |

105 000

725

|

135 000

930

|

115 000

795

|

Spec. 5 DP

|

| S |

135 000

930

|

165 000

1 140

|

145 000

1 000 000

|

Spec. 5 DP

|

|

Propiedades mecánicas de los grados de juntas de herramientas API |

||||

|

Fuerza de rendimiento

|

Fuerza de rendimiento

|

Resistencia a la tracción

|

Alargamiento

|

Caja

|

|

PSI

N/mm2

Min.

|

PSI

N/mm2

Max (max)

|

PSI

N/mm2

Min

|

En 2 pulgadas

%

Min

|

Dureza

Brinell

Min

|

|

120 000

827

|

165 000

1138

|

140 000

965

|

13 | 285 |

|

Requisitos de la composición química |

||||

|

Cuerpo del tubo |

Fósforo

% Máx.

|

Azufre

% Máx.

|

||

|

Cuerpo de tubería grado E

|

0.030

|

0.020

|

||

|

Cuerpo de tubería grados X, G y S

|

0.020

|

0.015

|

||

|

Herramienta conjunta

|

0.020 |

0.015

|

||

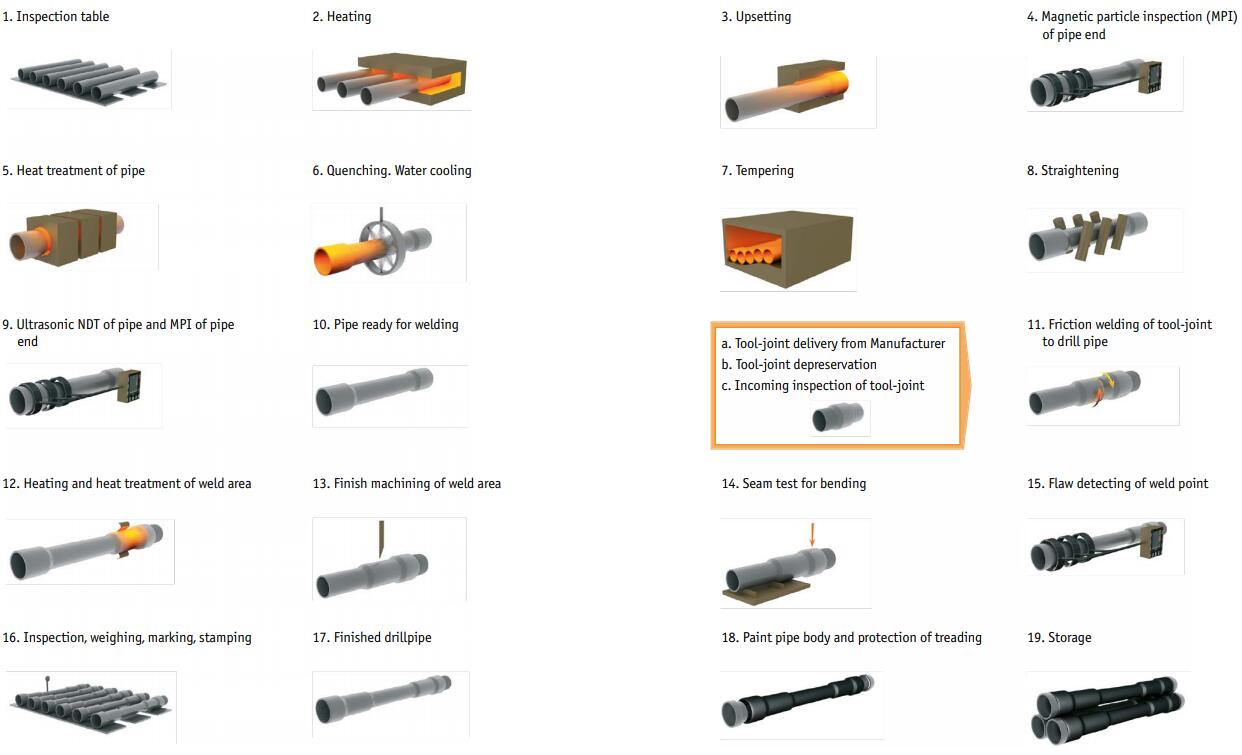

Detalles de la fabricación

Las juntas de herramienta están soldadas por inercia a los tubos con precisión monitoreada por computadora. La concentricidad se controla y controla cuidadosamente, y los parámetros de cada soldadura se registran electrónicamente y se pueden rastrear hasta cada junta.

Después de la eliminación del flash de soldadura, el área de soldadura se austeniza, se apaga y se templa para lograr las propiedades mecánicas requeridas. Los ciclos de tratamiento térmico para cada soldadura se comparan con parámetros específicos y se registran para su trazabilidad.

Después de que todos los pasos y las marcas de la máquina se pulen desde el área OD e ID, se utilizan pruebas de dureza, pruebas ultrasónicas e inspecciones de partículas magnéticas húmedas para verificar la integridad de cada zona de soldadura.

Rango dimensional de la tubería de perforación y propiedades de rendimiento

Thedrill pipeis una tubería de acero con roscas en el extremo, que se utiliza para conectar el equipo de superficie de la plataforma de perforación y el equipo de perforación y molienda o el dispositivo de orificio inferior en la parte inferior del pozo de perforación. El propósito de la tubería de perforación es transportar el lodo de perforación a la broca y junto con la broca para elevar, bajar o girar el dispositivo del orificio inferior. La tubería de perforación debe ser capaz de soportar una enorme presión interna y externa, torsión, flexión y vibración. En el proceso de extracción y refinación de petróleo y gas, la tubería de perforación se puede usar muchas veces.

|

Pipe Figures |

||||||||||

|

Plant |

NominalSize |

NominalWeight |

Wallthickness |

InsideDiameter |

Grade |

Upset |

TensileYield |

TorsionalYield |

InternalPressure |

Collapse |

|

in |

lb/ft |

in |

in |

lb |

ft-lb |

psi |

psi |

|||

|

mm |

kg/m |

mm |

mm |

kN |

Nm |

bar |

bar |

|||

|

3 |

2 3/8 60,3 |

6.65 9,34 |

0.280 7,11 |

1.815 46,13 |

E75 |

EU |

138 214 615 |

6 250 8 474 |

15 474 1 067 |

15 599 1 075 |

|

6.65 9,34 |

0.280 7,11 |

1.815 46,13 |

Х95 |

EU |

175 072 779 |

7 917 10 734 |

19 600 1 351 |

19 759 1 362 |

||

|

6.65 9,34 |

0.280 7,11 |

1.815 46,13 |

G105 |

EU |

193 500 861 |

8 751 11 864 |

21 663 1 493 |

21 839 1 505 |

||

|

3 |

2 7/8 73,0 |

10.4 15,49 |

0.362 9,19 |

2.151 54,64 |

E75 |

EU |

214 344 953 |

11 554 15 665 |

16 526 1 139 |

16 509 1 138 |

|

10.4 15,49 |

0.362 9,19 |

2.151 54,64 |

Х95 |

EU |

271 503 1208 |

14 635 19 842 |

20 933 1 443 |

20 911 1 441 |

||

|

10.4 15,49 |

0.362 9,19 |

2.151 54,64 |

G105 |

EU |

300 082 1335 |

16 176 21 932 |

23 137 1 595 |

23 112 1 593 |

||

|

10.4 15,49 |

0.362 9,19 |

2.151 54,64 |

S135 |

EU |

385 820 1716 |

20 798 28 198 |

29 747 2 051 |

29 716 2 048 |

||

|

3 |

3 1/2 88,9 |

13.3 19,81 |

0.368 9,35 |

2.764 70,20 |

E75 |

EU |

271 569 1208 |

18 551 25 152 |

13 800 951 |

14 113 973 |

|

13.3 19,81 |

0.368 9,35 |

2.764 70,20 |

Х95 |

EU |

343 988 1530 |

23 498 31860 |

17 480 1 205 |

17 877 1 232 |

||

|

13.3 19,81 |

0.368 9,35 |

2.764 70,20 |

G105 |

EU |

380 197 1691 |

25 972 35213 |

19 320 1 332 |

19 758 1 362 |

||

|

13.3 19,81 |

0.368 9,35 |

2.764 70,20 |

S135 |

EU |

488 825 2174 |

33 392 45 273 |

24 840 1 712 |

25 404 1 751 |

||

|

15.5 23,09 |

0.449 11,4 |

2.602 66,10 |

E75 |

EU |

322 775 1436 |

21 086 28 589 |

16 838 1 160 |

16 774 1 156 |

||

|

15.5 23,09 |

0.449 11,4 |

2.602 66,10 |

Х95 |

EU |

408 848 1819 |

26 708 36 211 |

21 328 1 470 |

21 247 1 465 |

||

|

15.5 23,09 |

0.449 11,4 |

2.602 66,10 |

G105 |

EU |

451 885 2010 |

29 520 40 023 |

23 573 1 625 |

23 484 1 619 |

||

|

15.5 23,09 |

0.449 11,4 |

2.602 66,10 |

S135 |

EU |

580 995 2585 |

37 954 51 459 |

30 308 2 090 |

30 194 2 081 |

||

|

3 |

4 101,6 |

14.0 20,85 |

0.330 8,38 |

3.340 84,84 |

E75 |

IU |

258 359 1269 |

23 288 31574 |

10 828 746 |

11 354 782 |

|

14.0 20,85 |

0.330 8,38 |

3.340 84,84 |

Х95 |

IU |

361 454 1608 |

29 498 39 994 |

13 716 945 |

14 382 992 |

||

|

14.0 20,85 |

0.330 8,38 |

3.340 84,84 |

G105 |

IU |

399 502 1777 |

32 603 44 204 |

15 159 1 045 |

15 896 1 096 |

||

|

Tool Joint Figures |

Assembly |

||||||||

|

Connection |

OutsideDiameter |

InsideDiameter |

TongLengthPin |

TongLengthBox |

TensileYield |

TorsionalYield |

Aprox. Weight |

TorsionalRatio, pinto pipe |

Make-uptorque |

|

in |

in |

in |

in |

lb |

ft-lb |

lb/ft |

ft-lb |

||

|

mm |

mm |

mm |

mm |

kN |

Nm |

kg/m |

Nm |

||

|

NC26 |

3 3/8 85,725 |

1 3/4 27,15 |

7 177,8 |

8 203,2 |

313 681 1 395 |

6 875 9 321 |

6.99 10,41 |

1.10 |

4 125 5 593 |

|

NC26 |

3 3/8 85,725 |

1 3/4 27,15 |

7 177,8 |

8 203,2 |

313 681 1 395 |

6 875 9 321 |

7.11 10,59 |

0.87 |

4 125 5 593 |

|

NC26 |

3 3/8 85,725 |

1 3/4 27,15 |

7 177,8 |

8 203,2 |

313 681 1 395 |

6 875 9 321 |

7.11 1059 |

0.79 |

4 125 5 593 |

|

NC31 |

4 1/8 104,8 |

2 1/8 53,98 |

7 177,8 |

9 228,6 |

447 130 1 989 |

11 790 15 985 |

10.87 16,19 |

1.02 |

7 122 9 656 |

|

NC31 |

4 1/8 104,8 |

2 50,80 |

7 177,8 |

9 228,6 |

495 726 2 205 |

13 158 17 839 |

11.09 16,52 |

0.90 |

7 918 10 735 |

|

NC31 |

4 1/8 104,8 |

2 50,80 |

7 177,8 |

9 228,6 |

495 726 2 205 |

13 158 17 839 |

11.09 16,52 |

0.81 |

7 918 10 735 |

|

NC31 |

4 3/8 111,1 |

1 5/8 41,28 |

7 177,8 |

9 228,6 |

623 844 2 775 |

16 809 22 790 |

11.55 17,20 |

0.81 |

10 167 13 785 |

|

NC38 |

4 3/4 120,7 |

2 11/16 68,26 |

8 203,2 |

10 1/2 266,7 |

587 308 2 613 |

18 071 24 500 |

13.93 20,75 |

0.97 |

10 864 14 730 |

|

NC38 |

5 127,0 |

2 9/16 65,09 |

8 203,2 |

10 1/2 266,7 |

649 158 2 888 |

20 095 27 245 |

14.62 21,78 |

0.86 |

12 196 16 536 |

|

NC38 |

5 127,0 |

2 7/16 61,91 |

8 203,2 |

10 1/2 266,7 |

708 063 3 150 |

22 035 29 875 |

14.71 21,91 |

0.85 |

13 328 18 070 |

|

NC38 |

5 127,0 |

2 1/8 53,98 |

8 203,2 |

10 1/2 266,7 |

842 440 3 748 |

26 503 35 933 |

14.92 22,22 |

0.79 |

15 909 21 570 |

|

NC38 |

5 127,0 |

2 9/16 65,09 |

8 203,2 |

10 1/2 266,7 |

649 158 2 888 |

20 095 27 245 |

16.54 24,64 |

0.95 |

12 196 16 536 |

|

NC38 |

5 127,0 |

2 7/16 61,91 |

8 203,2 |

10 1/2 266,7 |

708 063 3 150 |

22 035 29 875 |

16.82 25,05 |

0.86 |

13 328 18 070 |

|

NC38 |

5 127,0 |

2 1/8 53,98 |

8 203,2 |

10 1/2 266,7 |

842 440 3 748 |

26 503 35 933 |

17.03 25,37 |

0.90 |

15 909 21 570 |

|

NC40 |

5 1/2 139,7 |

2 1/4 57,15 |

7 177,8 |

10 254,0 |

979 996 4 360 |

32 693 44 325 |

17.57 26,17 |

0.86 |

19 766 26 799 |

|

NC40 |

5 1/4 133,4 |

2 13/16 71,44 |

7 177,8 |

10 254,0 |

711 611 3 166 |

23 279 31 562 |

15.04 22,40 |

1.00 |

17 092 19 106 |

|

NC40 |

5 1/4 133,4 |

2 11/16 68,26 |

7 177,8 |

10 254,0 |

776 406 3 454 |

25 531 34 615 |

15.34 22,85 |

0.87 |

15 404 20 885 |

|

NC40 |

5 1/2 139,7 |

2 7/16 61,91 |

7 177,8 |

10 254,0 |

897 161 3 991 |

29 764 40 354 |

15.91 23,70 |

0.91 |

18 068 24 497 |

|

Pipe Figures |

||||||||||

|

Plant |

NominalSize |

NominalWeight |

Wallthickness |

InsideDiameter |

Grade |

Upset |

TensileYield |

TorsionalYield |

InternalPressure |

Collapse |

|

in |

lb/ft |

in |

in |

lb |

ft-lb |

psi |

psi |

|||

|

mm |

kg/m |

mm |

mm |

kN |

Nm |

bar |

bar |

|||

|

4 |

4 1/2 114,3 |

16.6 24,73 |

0.337 8,56 |

3.826 97,18 |

E75 |

IEU |

330 558 1 470 |

30 807 41 774 |

9 829 678 |

10 392 717 |

|

16.6 24,73 |

0.337 8,56 |

3.826 97,18 |

X95 |

IEU |

418 707 1 863 |

39 022 52 914 |

12 450 859 |

12 765 880 |

||

|

16.6 24,73 |

0.337 8,56 |

3.826 97,18 |

G105 |

IEU |

462 781 2 059 |

43 130 58 484 |

13 761 949 |

13 825 953 |

||

|

16.6 24,73 |

0.337 8,56 |

3.826 97,18 |

S135 |

IEU |

595 004 2 647 |

55 453 75 194 |

17 693 1 220 |

16 773 1157 |

||

|

20.00 29,79 |

0.430 10,92 |

3.64 92,46 |

E75 |

IEU |

412 358 1 834 |

36 901 50 038 |

12 542 865 |

12 964 894 |

||

|

20.00 29,79 |

0.430 10,92 |

3.64 92,46 |

X95 |

IEU |

522 320 2 323 |

46 741 63 381 |

15 886 1 096 |

16 421 1132 |

||

|

20.00 29,79 |

0.430 10,92 |

3.64 92,46 |

G105 |

IEU |

577 301 2 568 |

51 661 70 052 |

17 558 1 211 |

18 149 1252 |

||

|

20.00 29,79 |

0.430 10,92 |

3.64 92,46 |

S135 |

IEU |

742 244 3 302 |

66 421 90 067 |

2 2575 1 557 |

23 335 1609 |

||

|

4 |

5 127,0 |

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

E75 |

IEU |

395 595 1 760 |

41 167 55 822 |

9 503 655 |

9 962 687 |

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

E75 |

IEU |

395 595 1 760 |

41 167 55 822 |

9 503 655 |

9 962 687 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

X95 |

IEU |

501 087 2 229 |

52 144 70 707 |

12 037 830 |

12 026 829 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

X95 |

IEU |

501 087 2 229 |

52 144 70 707 |

12 037 830 |

12 026 829 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

G105 |

IEU |

553 833 2 464 |

57 633 78 150 |

13 304 918 |

12 999 896 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

G105 |

IEU |

553 833 2 464 |

57 633 78 150 |

13 304 918 |

12 999 896 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

S135 |

IEU |

712 070 3 168 |

74 100 100 480 |

17 105 1180 |

15 672 1 081 |

||

|

19.50 29,05 |

0.362 9,19 |

4.276 108,62 |

S135 |

IEU |

712 070 3 168 |

74 100 100 480 |

17 105 1180 |

15 672 1 081 |

||

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

E75 |

IEU |

530 144 2 358 |

52 257 70 860 |

13 125 905 |

13 500 931 |

||

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

E75 |

IEU |

530 144 2 358 |

52 257 70 860 |

13 125 905 |

13500 931 |

||

|

Tool Joint Figures |

Assembly |

||||||||

|

Connection |

OutsideDiameter |

InsideDiameter |

TongLengthPin |

TongLengthBox |

TensileYield |

TorsionalYield |

Aprox. Weight |

TorsionalRatio, pinto pipe |

Make-uptorque |

|

in |

in |

in |

in |

lb |

ft-lb |

lb/ft |

ft-lb |

||

|

mm |

mm |

mm |

mm |

kN |

Nm |

kg/m |

Nm |

||

|

NC 46 |

6 1/4 158,8 |

3 1/4 82,55 |

7 177,8 |

10 254,0 |

901 164 4 009 |

33 228 45 057 |

18.37 27,35 |

1.09 |

20.396 27657 |

|

NC 46 |

6 1/4 158,8 |

3 76,20 |

7 177,8 |

10 254,0 |

1 048 426 4 664 |

38 998 52 881 |

18.79 27,98 |

1.01 |

20.396 27657 |

|

NC 46 |

6 1/4 158,8 |

3 76,20 |

7 177,8 |

10 254,0 |

1 048 426 4 664 |

38 998 52 881 |

18.79 27,98 |

0.91 |

23.795 32 266 |

|

NC 46 |

6 1/4 158,8 |

2 3/4 69,85 |

7 177,8 |

10 2 54,0 |

1 183 908 5 266 |

44 359 60 151 |

19.00 28,29 |

0.81 |

26.923 36 508 |

|

NC 46 |

6 1/4 158,75 |

3 76,20 |

7 177,8 |

10 254,0 |

1 048 426 4 664 |

38 998 52 881 |

22.09 32,89 |

1.07 |

23.795 32 266 |

|

NC 46 |

6 1/4 158,75 |

2 3/4 69,85 |

7 177,8 |

10 254,0 |

1 183 908 5 266 |

44 359 60 151 |

22.67 33,76 |

0.96 |

26.923 36 508 |

|

NC 46 |

6 1/4 158,75 |

2 1/2 63,50 |

7 177,8 |

10 254,0 |

1 307 608 5 817 |

49 297 66 847 |

22.86 34,03 |

0.96 |

29.778 40 379 |

|

NC 46 |

6 1/4 158,75 |

2 1/4 57,15 |

7 177,8 |

10 254,0 |

1 419 527 6 315 |

53 800 79 953 |

23.03 34,29 |

0.81 |

|

|

NC 50 |

6 5/8 168,28 |

3 3/4 95,25 |

7 177,8 |

10 254,0 |

939 095 4 177 |

37 269 50 537 |

20.85 31,05 |

0.92 |

22.836 30 966 |

|

51/2 FH |

7 177,8 |

3 3/4 95,25 |

8 203,2 |

10 254,0 |

1 448 407 6 443 |

62 903 85 296 |

22.28 33,17 |

1.53 |

|

|

NC 50 |

6 5/8 168,28 |

3 1/2 88,90 |

7 177,8 |

10 254,0 |

1 109 920 4 937 |

44 456 60 282 |

21.45 31,94 |

0.86 |

27.076 36 715 |

|

51/2 FH |

7 177,8 |

3 3/4 95,25 |

8 203,2 |

10 254,0 |

1 448 407 6 443 |

62 903 85 296 |

22.62 33,68 |

1.21 |

|

|

NC 50 |

6 5/8 168,28 |

3 1/4 82,55 |

7 177,8 |

10 254,0 |

1 268 963 5 645 |

51 217 69 450 |

21.93 32,65 |

0.89 |

31.025 42 070 |

|

51/2 FH |

7 177,8 |

3 3/4 95,25 |

8 203,2 |

10 254,0 |

1 448 407 6 443 |

62 903 85 296 |

22.62 33,68 |

1.09 |

|

|

NC 50 |

6 5/8 168,28 |

2 3/4 69,85 |

7 177,8 |

10 254,0 |

1551706 6903 |

63 393 85 961 |

22.61 33,67 |

0.86 |

38.044 51 588 |

|

51/2 FH |

7 1/4 184,15 |

3 1/2 88,90 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

72 213 97 921 |

23.48 34,96 |

0.98 |

43.490 58 972 |

|

NC 50 |

6 5/8 168,28 |

3 1/2 88,90 |

7 177,8 |

10 254,0 |

1 109 920 4 937 |

44 156 59 876 |

26.85 39,98 |

0.86 |

27.076 36 715 |

|

51/2 FH |

7 177,8 |

3 1/2 88,90 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

62 903 85 296 |

28.27 42,09 |

1.21 |

37.742 51 178 |

|

Pipe Figures |

||||||||||

|

Plant |

NominalSize |

NominalWeight |

Wallthickness |

InsideDiameter |

Grade |

Upset |

TensileYield |

TorsionalYield |

InternalPressure |

Collapse |

|

in |

lb/ft |

in |

in |

lb |

ft-lb |

psi |

psi |

|||

|

mm |

kg/m |

mm |

mm |

kN |

Nm |

bar |

bar |

|||

|

4 |

5 127,0 |

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

X95 |

IEU |

671 515 2 987 |

66 192 89 756 |

16 625 1 147 |

17 100 1179 |

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

X95 |

IEU |

671 515 2 987 |

66 192 89 756 |

16 625 1 147 |

17 100 1179 |

||

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

G105 |

IEU |

742 201 3 302 |

73 159 99 204 |

18 375 1 267 |

18 900 1303 |

||

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

G105 |

IEU |

742 201 3 302 |

73 159 99 204 |

18 375 1 267 |

18 900 1303 |

||

|

25.60 38,13 |

0.50 12,70 |

4.000 101,60 |

S135 |

IEU |

954 259 4 245 |

94 062 127 548 |

23 625 1 629 |

24 300 1676 |

||

|

4 |

5 1/2 139,7 |

21.90 32,62 |

0.361 9,17 |

4.778 121,36 |

E75 |

IEU |

437 116 1 944 |

50 710 68 763 |

8 615 594 |

8 413 580 |

|

21.90 32,62 |

0.361 9,17 |

4.778 121,36 |

X95 |

IEU |

553 681 2 463 |

64 233 87 100 |

10 912 753 |

10 019 691 |

||

|

21.90 32,62 |

0.361 9,17 |

4.778 121,36 |

G105 |

IEU |

611 963 2 722 |

70 994 96 258 |

12 061 832 |

10 753 742 |

||

|

21.90 32,62 |

0.361 9,17 |

4.778 121,36 |

S135 |

IEU |

786 809 3 500 |

91 278 123 773 |

15 507 1 069 |

12 679 874 |

||

|

24.70 36,79 |

0.415 10,54 |

4.670 118,62 |

E75 |

IEU |

497 222 2 212 |

56 574 76 714 |

9 903 683 |

10 464 722 |

||

|

24.70 36,79 |

0.415 10,54 |

4.670 118,62 |

X95 |

IEU |

629 814 2 802 |

71 660 97 171 |

12 544 865 |

12 933 892 |

||

|

24.70 36,79 |

0.415 10,54 |

4.670 118,62 |

G105 |

IEU |

696 111 3 097 |

79 204 107 401 |

13 865 956 |

14 013 966 |

||

|

24.70 36,79 |

0.415 10,54 |

4.670 118,62 |

S135 |

IEU |

894 999 3 981 |

101 833 138 086 |

17 826 1229 |

17 023 1 174 |

||

|

Tool Joint Figures |

Assembly |

||||||||

|

Connection |

OutsideDiameter |

InsideDiameter |

TongLengthPin |

TongLengthBox |

TensileYield |

TorsionalYield |

Aprox. Weight |

TorsionalRatio, pinto pipe |

Make-uptorque |

|

in |

in |

in |

in |

lb |

ft-lb |

lb/ft |

ft-lb |

||

|

mm |

mm |

mm |

mm |

kN |

Nm |

kg/m |

Nm |

||

|

NC 50 |

6 5/8 168,28 |

3 76,20 |

7 177,8 |

10 254,0 |

1 416 225 6 300 |

57 534 78 016 |

27.87 41,50 |

0.86 |

34.680 47026 |

|

51/2 FH |

7 177,8 |

3 1/2 88,90 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

62 903 85 296 |

28.59 42,57 |

0.95 |

37.742 51178 |

|

NC 50 |

6 5/8 168,28 |

2 3/4 69,85 |

7 177,8 |

10 254,0 |

1 619 231 7 203 |

63 393 85 961 |

28.32 42,17 |

0.87 |

38.044 51588 |

|

51/2 FH |

7 1/4 184,15 |

3 1/2 88,90 |

8 203,2 |

10 254,0 |

1 551 706 6 903 |

72 213 97 921 |

29.16 43,42 |

0.99 |

43.490 58972 |

|

51/2 FH |

7 1/4 184,15 |

3 1/4 82,55 |

8 203,2 |

10 254,0 |

1 778 274 7 910 |

78 716 106 739 |

29.43 43,82 |

0.83 |

47.230 64044 |

|

51/2 FH |

7 177,8 |

4 101,60 |

8 203,2 |

10 254,0 |

1 265 802 5 631 |

55 687 75 512 |

23.77 35,39 |

1.11 |

33.560 45507 |

|

51/2 FH |

7 177,8 |

3 3/4 95,25 |

8 203,2 |

10 254,0 |

1 448 407 6 443 |

62 903 85 296 |

24.53 36,53 |

0.98 |

37.742 51178 |

|

51/2 FH |

7 1/4 184,15 |

3 1/2 88,9 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

72 213 97 921 |

25.38 37,79 |

1.02 |

43.490 58972 |

|

51/2 FH |

7 1/2 190,50 |

3 76,20 |

8 203,2 |

10 254,0 |

1 925 536 8 566 |

86 765 117 653 |

26.50 39,46 |

0.96 |

52.302 70922 |

|

51/2 FH |

7 177,8 |

4 101,60 |

8 203,2 |

10 254,0 |

1 265 802 5 631 |

55 687 75 512 |

26.33 39,21 |

0.99 |

33.560 45507 |

|

51/2 FH |

7 1/4 184,15 |

3 1/2 88,9 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

72 213 97 921 |

27.85 41,47 |

1.01 |

43.490 58972 |

|

51/2 FH |

7 1/4 184,15 |

3 1/2 88,9 |

8 203,2 |

10 254,0 |

1 619 231 7 203 |

72 213 97 921 |

27.85 41,47 |

0.92 |

43.490 58972 |

|

51/2 FH |

7 1/2 190,50 |

3 76,20 |

8 203,2 |

10 254,0 |

1 925 536 8 566 |

86 765 117 653 |

27.77 41,35 |

0.86 |

52.302 70922 |

Estándar: API 5DP

Grado: E75, X95, G105, S135, SS-105