Especificaciones clave

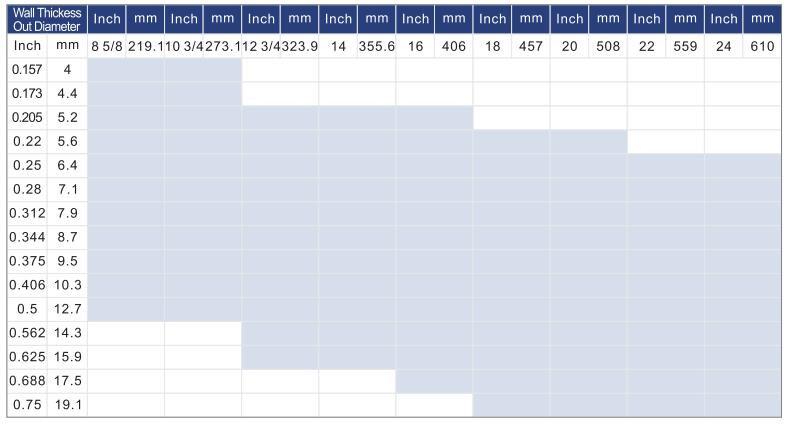

Diámetro: 1/2 pulgada a 24 pulgadas (21,34mm a 609,6mm)

Espesor de pared: 0,5mm-20mm

Estándares: ASTM A53, API 5L, EN 10219

Material: ASTM A53 Grado B, API 5L Grado B, X42, X52, X60, X70, S235, S275, S355

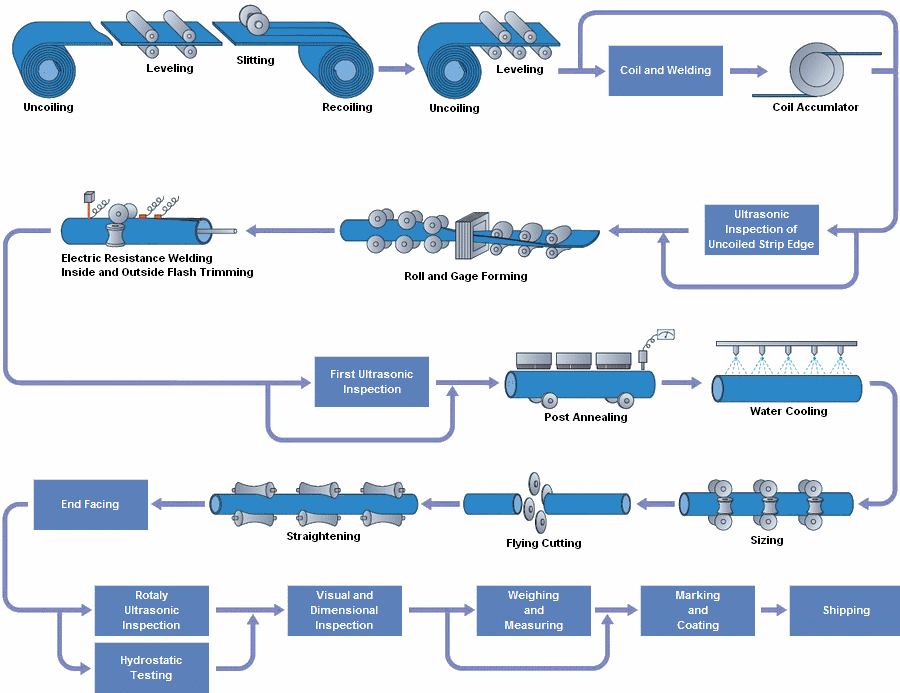

Proceso de producción

Selección de material: se seleccionan bobinas de acero al carbono de alta calidad.

Formación: Las bobinas se forman en una forma cilíndrica utilizando rodillos de precisión.

Soldadura: los bordes se sueldan mediante soldadura por inducción de alta frecuencia.

Tratamiento térmico: La normalización se realiza para mejorar las propiedades mecánicas.

Acabado: Las tuberías son pulidas, limpiadas e inspeccionadas para cumplir con los estándares internacionales.

Aplicaciones

Transporte de agua y gas

Aplicaciones estructurales y mecánicas

Sistemas de baja a media presión

Ventajas

Rentable: menores costos de producción en comparación con las tuberías sin costura.

Versatilidad: Disponible en una amplia gama de tamaños y espesores.

Superficie lisa: Las uniones soldadas están pulidas para asegurar una superficie interior lisa.