Key Specifications

Diameter: 1/2 inch to 24 inches (21.34 mm to 609.6 mm)

Wall Thickness: 0.5mm-20mm

Standards: ASTM A53, API 5L, EN 10219

Material: ASTM A53 Grade B, API 5L Grade B, X42, X52, X60, X70, S235, S275, S355

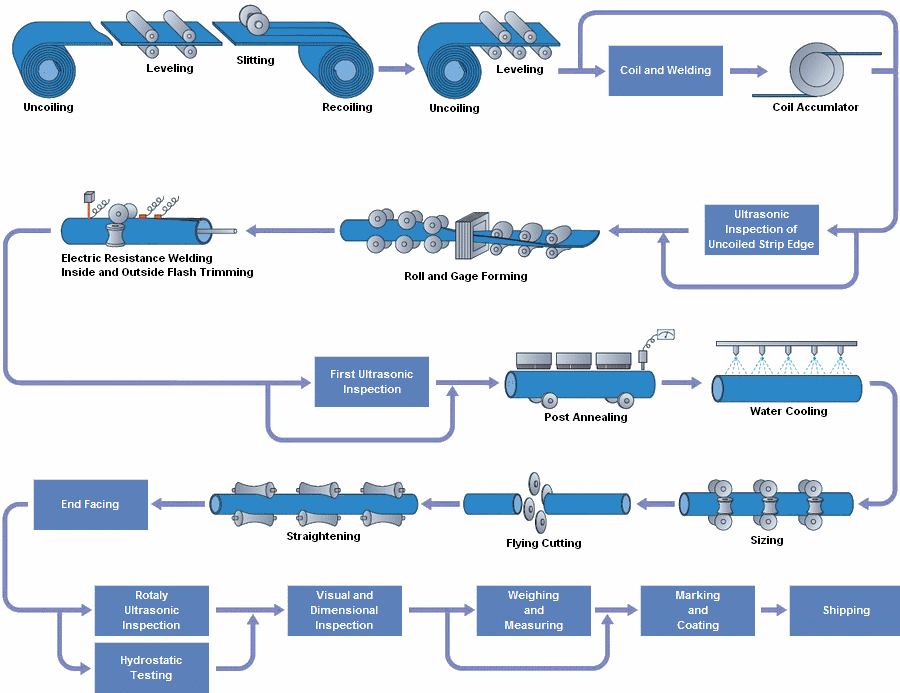

Production Process

Material Selection: High-quality carbon steel coils are selected.

Forming: The coils are formed into a cylindrical shape using precision rollers.

Welding: The edges are welded using high-frequency induction welding.

Heat Treatment: Normalizing is performed to enhance mechanical properties.

Finishing: The pipes are polished, cleaned, and inspected to meet international standards.

Applications

Water and gas transportation

Structural and mechanical applications

Low to medium-pressure systems

Advantages

Cost-Effective: Lower production costs compared to seamless pipes.

Versatility: Available in a wide range of sizes and thicknesses.

Smooth Surface: Welded joints are polished to ensure a smooth interior surface.