Key Specifications

Diameter: 1/2 inch to 24 inches (21.34 mm to 609.6 mm)

Wall Thickness: 0.5 mm to 50 mm

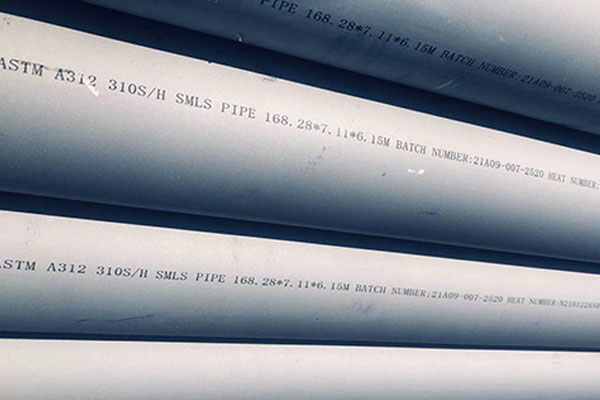

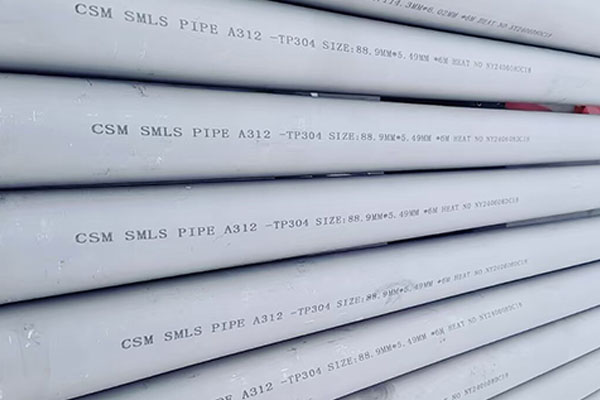

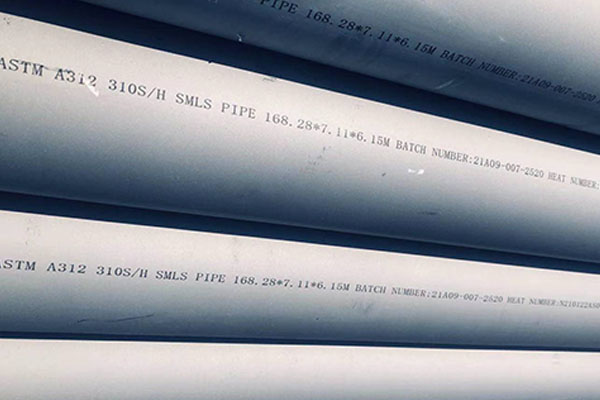

Standards: ASTM A312, ASTM A213, EN 10216-5, JIS G3459

Material: 304/304L, 316/316L, 321, 310S, 904L, Duplex 2205

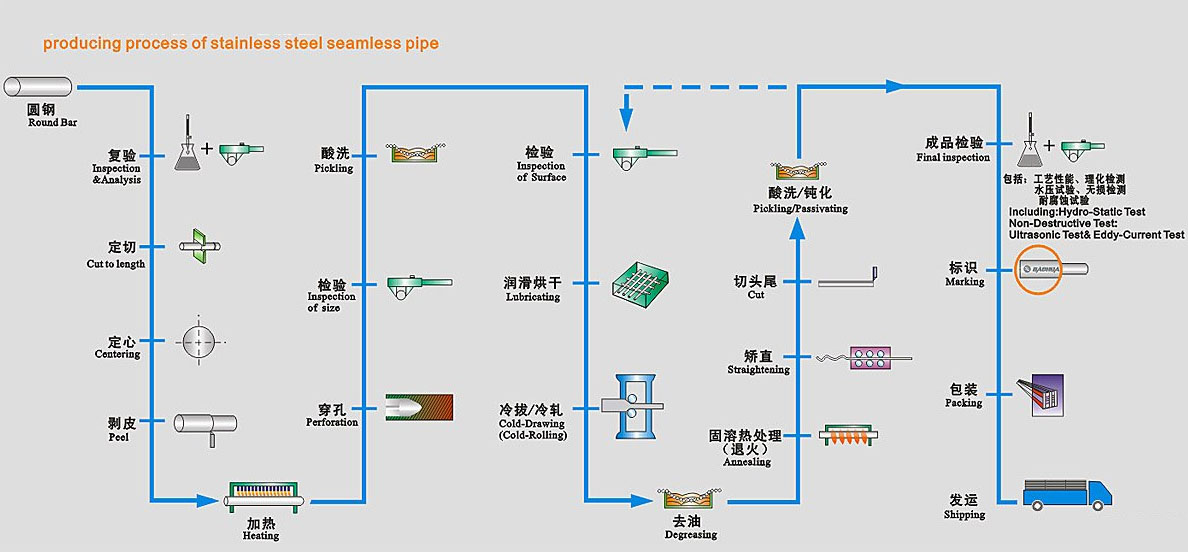

Production Process

Billet Preparation: High-quality stainless steel billets are heated to a high temperature.

Extrusion: The billet is extruded through a die to form a hollow shell.

Cold Drawing: The pipe is further processed through cold drawing to achieve precise dimensions and surface finish.

Heat Treatment: Solution annealing is performed to restore microstructure and enhance properties.

Inspection: The pipes undergo rigorous testing, including ultrasonic and hydrostatic tests, to ensure quality.

Applications

Oil and gas exploration and refining

Power generation (boiler and heat exchanger tubes)

Pharmaceutical and biotechnology industries

High-pressure hydraulic systems

Nuclear and thermal power plants

Advantages

High Strength: No welded seams, making them stronger and more reliable for high-pressure applications.

Uniformity: Consistent wall thickness and smooth interior surface.

High-Temperature Resistance: Suitable for extreme temperature conditions.

Corrosion Resistance: Excellent performance in corrosive environments.