Key Specifications

Diameter: 219mm-3620mm

Wall Thickness: 6 mm to 25 mm

Standards: API 5L, ASTM A53, ASTM A252, EN 10219, EN 10217

Material: API 5L Grade B, X42, X52, X60, X65, X70, GR.1, GR.2,GR.3, S235, S275, S355

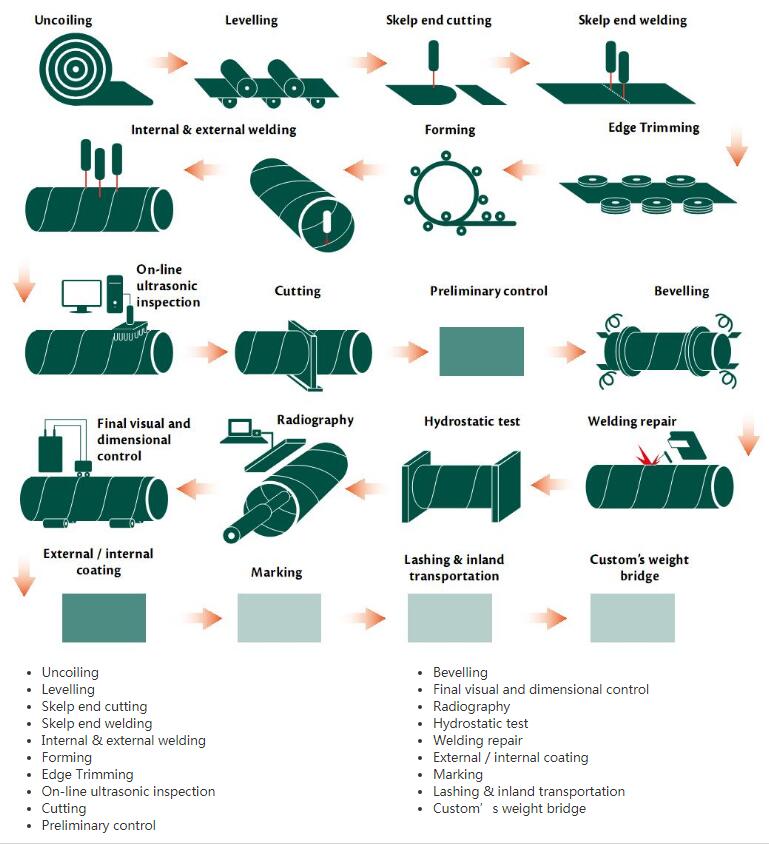

Production Process

Plate Preparation: High-quality carbon steel plates are selected.

Forming: The plates are formed into a spiral shape using a spiral forming machine.

Welding: The spiral seam is welded using submerged arc welding (SAW).

Heat Treatment: Normalizing or quenching and tempering is performed.

Inspection: The pipes undergo rigorous testing, including ultrasonic and radiographic tests.

Applications

Oil and gas transmission pipelines

Water and sewage transportation

Structural and heavy-duty applications

Advantages

High Strength: Suitable for high-pressure and large-diameter applications.

Durability: Excellent performance in harsh environments.

Customization: Available in various grades and specifications.