Standard:

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210:S235,S355,S235JRH,

S355J2H,S355NH

EN 10219:S235,S355,S235JRH,

S275J0H, S275J2H, S355J0H, S355J2H

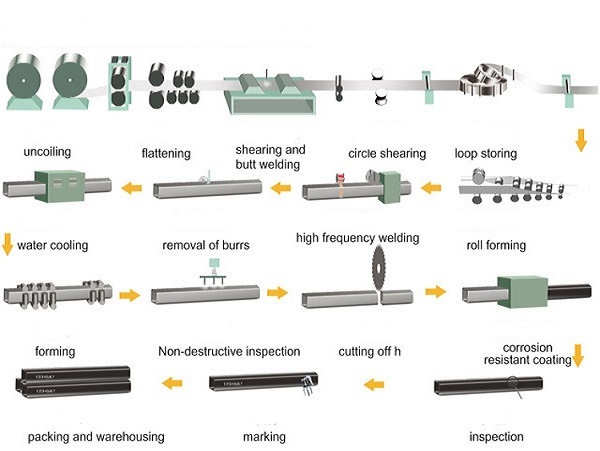

Production process:

Hot rolled

Cold rolled

MS Rectangular tube sizes (It can be customized according to customer requirements)

Chemical composition of material

| Grade |

element |

C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% max (Norminal W.T.(mm) | Si% max | Mn% max | P% max | S% max | N% max | |

|

and IC 10 |

|

≤ 40 |

|

|||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Mechanical properties of material

| Grade |

Yield Strength |

Tensile Strength |

Elongation |

|

A500.Gr.b |

46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Yield Strength | Tensile Strength | Min.elogation | Min.percent properties | ||||||||

|

Acc.to EN10027/1 and IC 10

|

Acc.to EN10027/2 | Norminal W.T.mm | Norminal W.T.mm | Longit. | Cross | Test temperature°C | Average min.impact value | |||||

|

≤16 |

>6 |

>40 |

<3 |

≤3≤65 |

Norminal W.T.mm |

|||||||

|

≤65 |

≤65 |

≤40 |

>40 |

>40 |

≤65 |

|||||||

|

≤65 |

≤40 |

|||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

|

S355JOH |

1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Equivalent specfications

|

EN 10210-1 |

NF A 49501 NF A 35501 |

DIN 17100 DIN 17123/4/5 |

BS 4360 |

UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | – | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | – | St E 285 N | – | – |

| S275NLH | – | TSt E 285 N | 43 EE | – |

| S355NH | E 355 R | St E 355 N | – | – |

| S355NLH | – | TSt E 355 N | 50 EE | – |

| S460NH | E 460 R | St E 460 N | – | – |

| S460NLH | – | TSt E 460 N | 55 EE | – |

– block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

– the next fi gure means the minim. yield value required for wall thickness ≤16 mm

– "J2" means impact test value -20° C min. 27 joule

– block letter "H" means "HOLLOW SECTION".