Before Cutting Pipe and Tubing

No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting.

After Cutting Pipe and Tubing

Unless a cut is perfectly clean, you should expect to remove burrs from around the edge, especially after sawing.

Use a deburring tool to clean the edge after tube cutting.

You may opt to use a metal file on the cut of a metal pipe.

CNC Pipe Cutter--ProCutter 600–900

Our CNC Pipe Cutters, ProCutter 600 and 900, incorporate all of HGG’s advanced technology and expertise. Operational excellence is applied to keep costs low. They come with oxy-fuel, plasma, marking and CAD-CAM Interfaces.

High value CNC Pipe Cutter

Savings on fitting & welding

Full penetration welds

Minimum:48 mm(2")

Maximum:910 mm( 36")

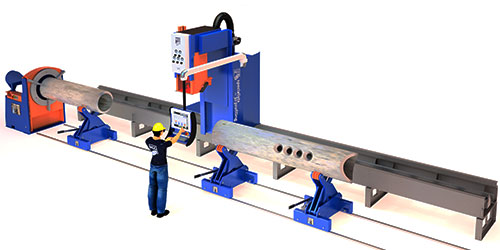

Pipe Cutting Machine; chuck type--SPC 500–1200 PT

The SPC 500–1200 Stationary Pipe Cutting Machine is able to process a wide variety of materials, sizes and wall thicknesses making it suitable for all kinds of applications. It comes with oxy-fuel, plasma, marking and CAD-CAM interfaces.

Savings on fitting and welding

Operator safety first

CAD to machine

Minimum:48 mm (2")

Maximum:1220 mm (48")

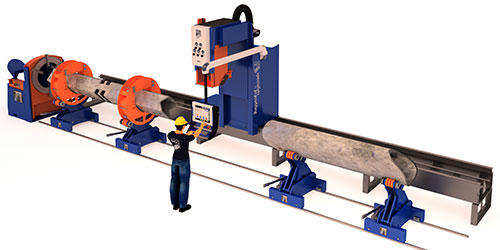

Pipe Cutting Line; roller bed type with floating chuck--SPC 660–1200 RB

The SPC 660–1200 RB Pipe Cutting Line from HGG combines the roller bed principle for an uninterrupted material flow while controlling the rotation of the material with a floating chuck registering linear displacement.

Continuous material flow

Perfect cutting shapes

CAD to machine

Minimum:48 mm (2")

Maximum:1225 mm (48")

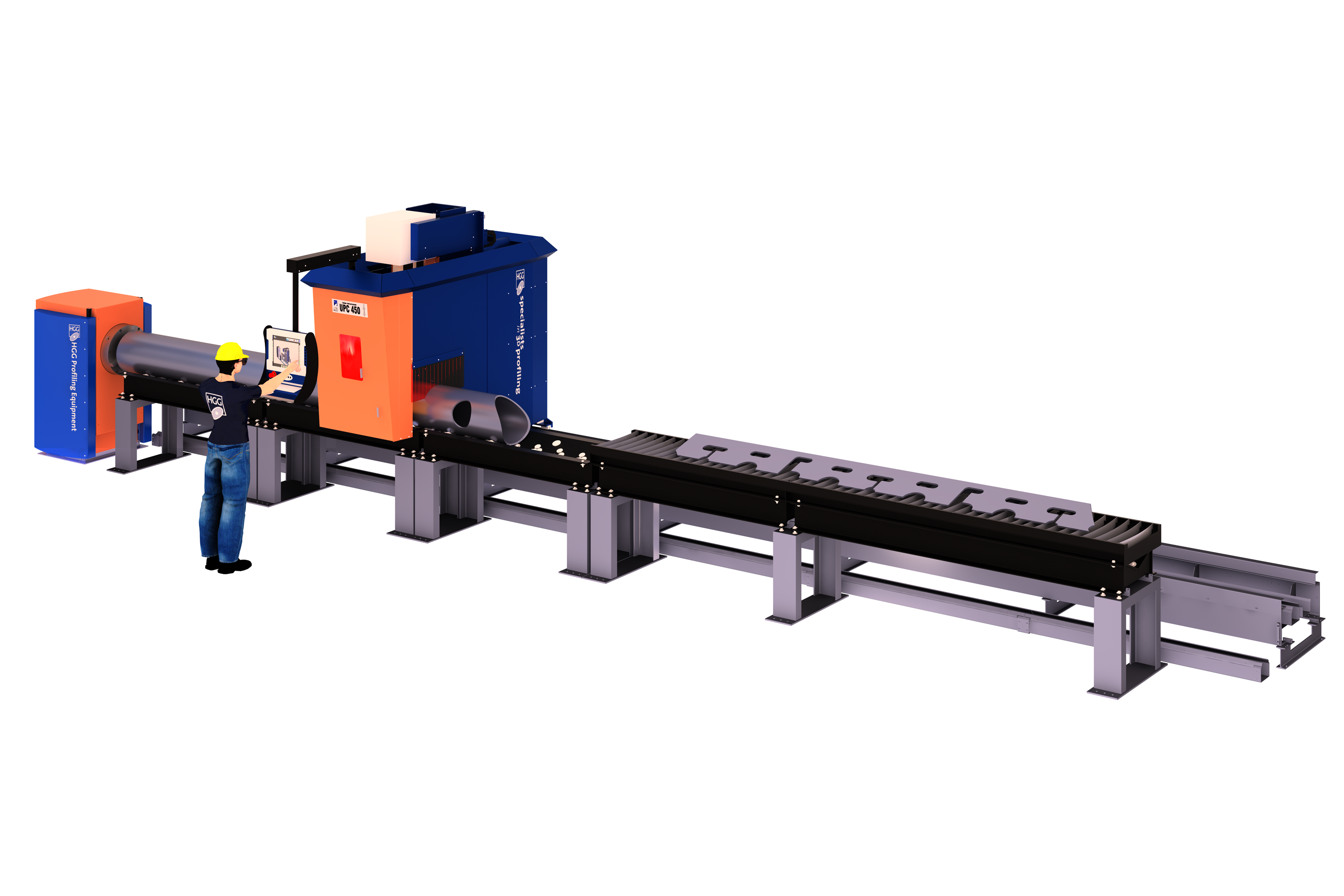

Pipe and Box section Cutting Machine--MPC 450 I 500–1200

Pipe and square tube cutting machine for automated 3D pipe and box cutting. The MPC is highly accurate and versatile and combines three machines into one.

Quick switch b/n pipe and box cutting

Smooth weld details

Perfect fit length

Minimum:48 mm (2")

Maximum:1225 mm (48")

CNC Pipe Cutting machine for vessels and offshore--SPC 1500–3000 PT

The SPC 1500–3000 CNC Pipe Cutting Machine is a very robust machine built to handle large pipe diameters and heavy weights. Everything in the machine is designed and implemented with the purpose to guarantee extreme tolerances during cutting.

Holes Truly Round

Elimination of Lay-out

Thick Wall Accuracy

Minimum:75 mm (60")

Maximum: 3000 mm (118")

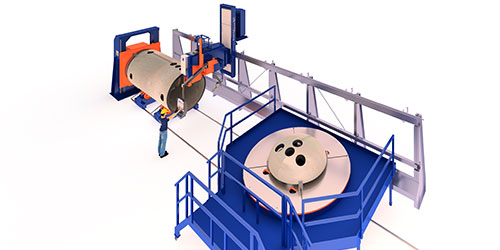

Pipe and Vessel Head Cutting machine--SPC 1500–3000 VC

The SPC 1500–3000 VC pipe and vessel head cutting machine is the answer to pressure vessel manufacturers struggling with and spending too much time on lay outs. The VHC saves you time on cutting, fitting and welding.

Savings on fitting and welding

Elimination of lay-out

Dish heads and vessels

Minimum:75 mm (3")

Maximum: 3000 mm (118")

CNC Pipe Cutting Line; roller bed type--RBPC 660–2000

The RBPC 660–2000 is a highly productive CNC pipe cutting line driven by a roller bed. It comes with wheels sets and torch-to-material distance sensors dealing with pipe behavior during rotation.

Uninterrupted material flow

Perfect fit

Perfect cutting shapes

Minimum:48 mm (2")

Maximum:2035 mm (80")

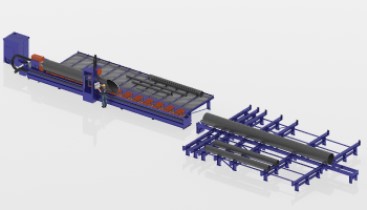

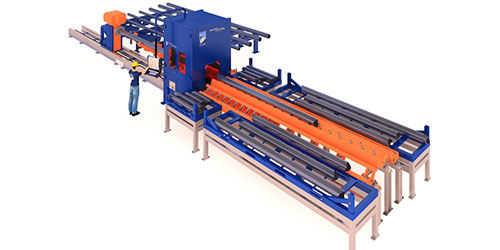

Pipe and Tube Cutting Line--TCL 400

The TCL 400 Plasma Pipe and Tube Cutting Line is the next generation 3D cutting machine for pipe and tube. The highly productive TCL is the answer to automated but expensive tube laser cutting machines.

Unparalleled productivity

User safety

Material sorting

Minimum:48 mm (2")

Maximum406 mm (16")

Profile Cutting Machine--Ship Profiler

Our Ship Profiler offers automated profile cutting for an affordable price, combining high productivity with a small footprint.

Automation & high productivity for an affordable price

Operator safety through optimized fume exhaust

3D laser measurement for accurate cutting

Minimum: 60x5 mm (2x0.2")

Maximum:450x30 mm (17.7x1.2")

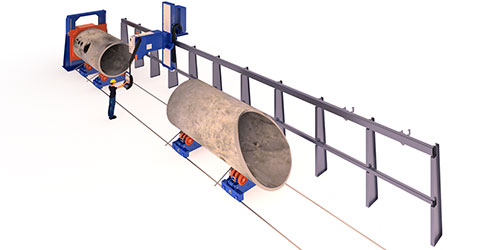

Pipe profiler with rollerbed---ProCutter 900 RB

The ProCutter 900 RB is a pipe profiler which is logistically optimized. This affordable tube profiling machine is a true workhorse which incorporates all of HGG’s advanced technology and expertise. Operational excellence is applied to keep costs low.

High productivity

Easy material handling

A true workhorse

Minimum:48mm (2")

Maximum:914 mm (36")