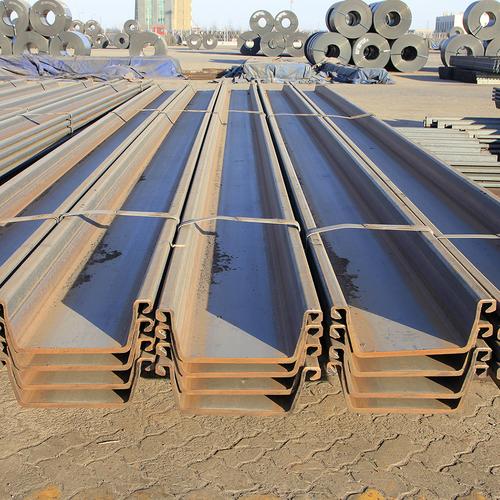

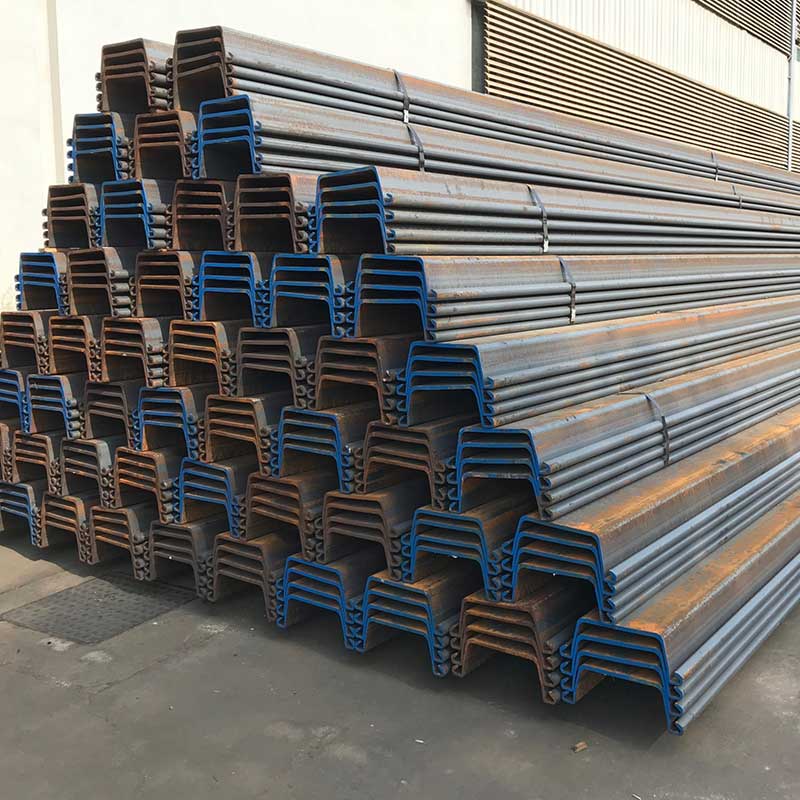

U-shaped Steel Sheet Pile

U-shaped profile interlocked on both sides to form a continuous wall with centerline in the middle of a double U section wall.

1) U-shaped steel sheet pile specifications and models are rich.

2) Combination of great wave depth and high flange thickness leads to excellent statical properties

3) According to the European standard design and production, symmetrical structure form, is conducive to repeated use, in repeated use, and hot rolling equivalent.

4) The length can be customized according to customer requirements, which brings great convenience to the construction and reduces the cost.

5) Due to the convenient production, it can be customized in advance when used together with the composite pile.

6) The production design and production cycle are short, and the performance of the steel sheet pile can be determined according to customer requirements.

The steel sheet pile is very wide, in the permanent structure of the building, can be used for wharf, unloading yard, embankment revetment, wall, retaining wall, breakwater, diversion embankment, dock, gate, etc.; In temporary structures, can be used to seal the mountain, temporary shore expansion, cut-off, bridge cofferdam, large pipeline laying temporary ditch excavation retaining, water, sand, and so on; In flood fighting, it can be used for flood control, collapse prevention, sand and so on.

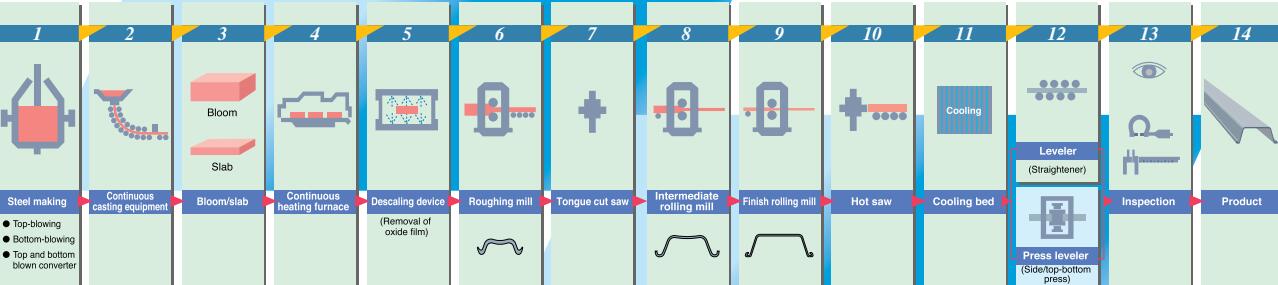

Hot Rolled steel sheet pile

|

Model |

Width |

Height |

Web |

single wood |

per meter board |

Execution standard |

||||||

|

Cross-Sectional Area |

Weight |

Moment of Inertia |

Section Modulus |

Cross-Sectional Area |

Weight |

Moment of Inertia |

Section Modulus |

|||||

|

W*H |

mm |

mm |

mm |

cm2 |

kg/m |

Ix cm4 |

Wx cm3 |

cm2 |

kg/m |

Ix cm4 |

Wx cm3 |

|

|

PU 400*100 |

400 |

100 |

10.5 |

61.18 |

48 |

1240 |

152 |

153 |

120.1 |

8740 |

874 |

(1) National standard: GB/T 20933-2014 |

|

PU 400*125 |

400 |

125 |

13.0 |

76.42 |

60 |

2220 |

223 |

191 |

149.9 |

16800 |

1340 |

|

|

PU 400*150 |

400 |

150 |

13.1 |

74.40 |

58.4 |

2790 |

250 |

186 |

146.0 |

22800 |

1520 |

|

|

PU 400*170 |

400 |

170 |

15.5 |

96.99 |

76.1 |

4670 |

362 |

242.5 |

190.4 |

38600 |

2270 |

|

|

PU 500*200 |

500 |

200 |

24.3 |

133.80 |

105 |

7960 |

520 |

267.6 |

210.1 |

63000 |

3150 |

|

|

PU 500*225 |

500 |

225 |

27.6 |

153.00 |

120.1 |

11400 |

680 |

306 |

240.2 |

86000 |

3820 |

|

|

PU 600*130 |

600 |

130 |

10.3 |

78.70 |

61.8 |

2110 |

203 |

131.2 |

103.0 |

13000 |

1000 |

|

|

PU 600*180 |

600 |

180 |

13.4 |

103.90 |

81.6 |

5220 |

376 |

173.2 |

136.0 |

32400 |

1800 |

|

|

PU 600*210 |

600 |

210 |

18.0 |

135.30 |

106.2 |

8630 |

539 |

225.5 |

177.0 |

56700 |

2700 |

|

Contrast material

|

Standard |

Grade |

Chemical composition |

||||||||||

|

C |

Si |

Mn |

P |

S |

Nb |

V |

Ti |

Cu |

N |

free nitrogen |

||

|

≤ |

||||||||||||

|

JIS A 5528 |

SY295 |

|

|

|

0.04 |

0.04 |

|

|

|

|

|

|

|

SY390 |

|

|

|

0.04 |

0.04 |

|

|

|

|

|

|

|

|

JIS A 5523 |

SYW295 |

0.18 |

0.55 |

0.15 |

0.04 |

0.04 |

|

|

|

|

|

0.006 |

|

SYW390 |

0.18 |

0.55 |

0.15 |

0.04 |

0.04 |

|

|

|

|

|

0.006 |

|

|

GB1591 |

Q345B |

0.2 |

0.5 |

1.7 |

0.035 |

0.035 |

0.07 |

0.15 |

0.2 |

0.3 |

0.12 |

|

|

GB/T20933-2014 |

Q295P |

0.16 |

0.5 |

1.5 |

0.035 |

0.035 |

0.06 |

0.15 |

0.2 |

|

|

|

|

Q345P |

0.2 |

0.5 |

1.7 |

0.035 |

0.035 |

0.06 |

0.15 |

0.2 |

|

|

|

|

|

Q390P |

0.2 |

0.5 |

1.7 |

0.035 |

0.035 |

0.06 |

0.2 |

0.2 |

|

|

|

|

|

Q420P |

0.2 |

0.5 |

1.7 |

0.035 |

0.035 |

0.06 |

0.2 |

0.2 |

|

|

|

|

|

Q460P |

0.2 |

0.6 |

1.8 |

0.03 |

0.03 |

0.11 |

0.2 |

0.2 |

|

|

||