The comparison of common chemical compositions of ASTM A36 steel and AISI 1018 steel is shown as follows:

|

Element |

ASTM A36 |

AISI 1018 |

|

C |

≤0.25% |

0.15–0.20% |

|

Mn |

0.8–1.2% |

0.6–0.9% |

|

Si |

≤0.40% |

≤0.30% |

|

S/P |

≤0.05% |

≤0.04% |

3. Mechanical performance comparison

ASTM A36 steel

Yield strength: 250 MPa (36 ksi)

Tensile strength: 400-550 MPa

Elongation: Approximately 20%

AISI 1018 steel

Yield strength: 370 MPa

Tensile strength: 440 MPa

Elongation: Approximately 15%

ASTM A36 steel maintains a good balance in strength and ductility and is highly suitable for structural applications. 1080 steel is more suitable for processing in precision machinery but not for large-scale structural components.

4. Weldability and processability

Steel A36: It has excellent welding performance and is suitable for various processes such as arc welding, gas welding, submerged arc welding, manual welding and automatic welding.

Steel 1018: Excellent processing performance, suitable for turning, drilling and processing parts. The welding performance is average, and the welding of large-scale structures is not as convenient as that of A36.

Advantages of A36: The welding of large-sized structural components is simple, saving labor and costs, making it the preferred choice for structural processing.

5. Heat treatment and hardening properties

A36 steel: ASTM A36 steel is usually delivered and used in a hot-rolled state without the need for additional heat treatment. The low carbon content of this type of steel enables it to maintain a certain strength while having good toughness and ductility.

1018 steel: AISI 1018 steel, due to its low carbon content, has relatively low strength by itself, but it has excellent carburizing properties. When it is necessary to increase the surface hardness, heat treatment processes such as carburizing, quenching and tempering can be adopted to significantly enhance the surface hardness, while the core still maintains good toughness and ductility.

6. Comparison of application fields

ASTM A36 steel:

Building structures (Bridges, steel frames)

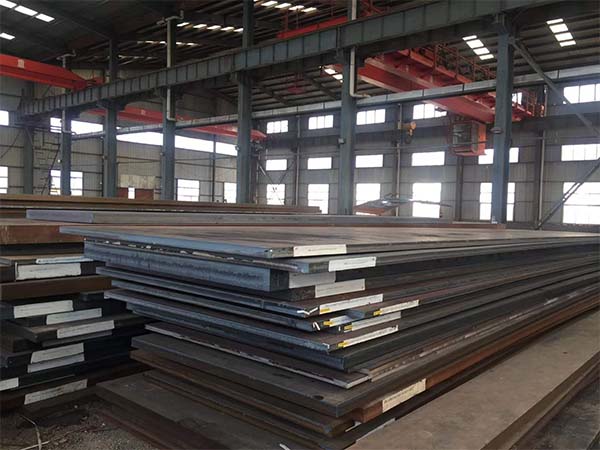

Structural components (section steel, Angle steel, steel plate)

Support structure for oil and gas engineering

Heavy machinery bases and welded parts

AISI 1018 steel:

Gears, shafts, pins

Bolts, nuts, auto parts

Small precision parts

Why choose ASTM A36 steel?

A comprehensive comparison shows that:

A36 steel: Economical and practical, with good welding performance, suitable for large-scale structural projects.

Steel 1018: Suitable for processing precision parts, but not as practical as A36 in large-scale projects.

If your project involves Bridges, buildings, pipelines or other large structural components, ASTM A36 steel is a more ideal choice. Its strength, supply volume and cost advantages make it one of the most popular structural steels in the world.

Looking for a reliable supplier of ASTM A36 steel? CENTRAL STEEL is a well-known manufacturer and exporter of pipes, plates, sections and fittings in China. Contact us for specification sheets, quotations and professional advice to provide you with cost-effective steel solutions for your projects.

Read more : What is the meaning of A36 plates