The

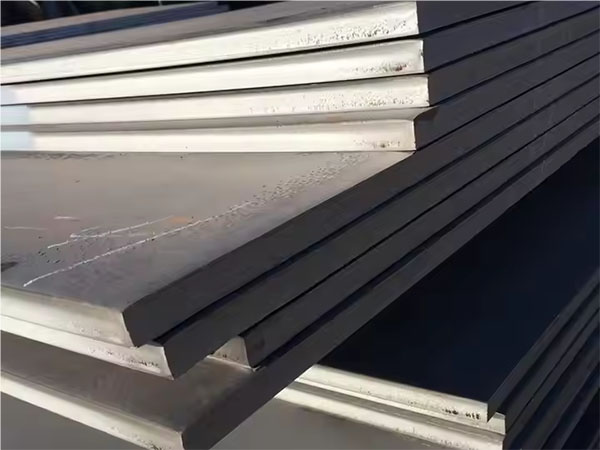

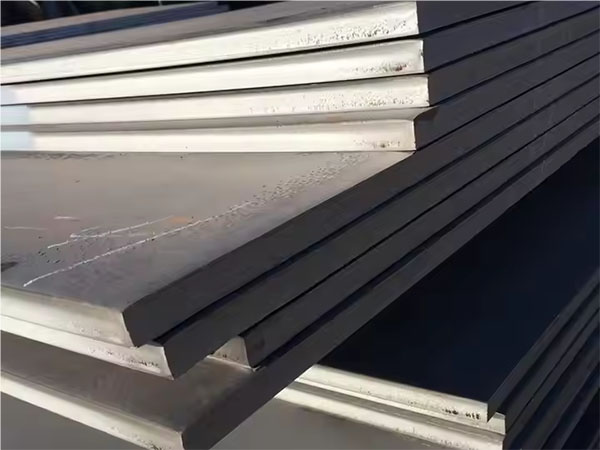

ASTM A36 steel plate is a low-carbon structural steel plate produced in accordance with the American Society for Materials and Testing (ASTM) A36 standard. With good strength, formability and weldability, it is also an excellent magnetic field conductor, which is widely used in various fields from construction to automotive manufacturing. It is one of the most commonly used carbon steel grades.

A36 Meaning of the name

The A36 is named for its mechanical properties rather than its chemical properties. In the

ASTM system, A represents ferrous or iron-related materials, while 36 represents a minimum yield strength of

36,000 Psi. The ASTM A36 standard specifies the mechanical properties of A36 steel and its chemical composition. This designation ensures that the steel meets the necessary standards for structural applications, providing a benchmark for manufacturers and engineers. ASTM A36 is suitable for a variety of shapes and sizes, including steel plates, rebar and beams.

A36 steel plate manufacturing process

A36 steel plate is mainly produced by

hot rolling process, the main process of production includes: raw material preparation, smelting, casting, heating and hot rolling processing, cooling, cutting and straightening, surface treatment, quality testing and packaging. Among them, the temperature should be kept above

1,700°F when heating the billet to ensure that the billet is heated evenly and prepared for the subsequent hot rolling.

Chemical composition of A36 steel plate

Steel is usually composed of iron and carbon, and small amounts of other elements are added to the alloy to change the chemical and mechanical properties of the steel. Like other steels, A36 steel mainly contains iron, but also contains small amounts of other elements. The main chemical components are:

Carbon (C) :

0.25% (Max)

Copper (Cu) :

0.20% (minimum)

Iron (Fe) :

98%

Manganese (Mn) :

1.03%

Phosphorus (P) :

0.04% (Max)

Sulfur (S) :

0.05% (Max)

Silicon (Si) :

0.28% (Max)

The content of each element in a36 steel plates varies. Due to its low-carbon characteristics, a36 steel plates have excellent welding and processing properties, making them highly suitable for cutting, welding, stamping and forming processes. They are ideal materials for the construction field.

The mechanical properties of A36 steel plate

The yield strength of A36 steel plate is not less than 36 ksi (about

250 MPa), and the tensile strength is usually between 58 and 80 ksi (about

400 to 550 MPa), which can meet the requirements of most structural engineering for strength and toughness. The elongation at break of steel plates not exceeding 200 mm in thickness is 20%. It has good notch toughness at low temperature and is suitable for molding process.

Advantages of A36 steel plate

Excellent processing performance: A36 steel plate is easy to cut, press, weld and heat treatment, so that it shows high flexibility in various processing processes, and can meet the manufacturing requirements of various complex shapes and sizes. Good welding performance, can adopt any form of welding method for welding, even in the field construction can achieve fast and reliable connection.

Cost-effectiveness: As a low-carbon structural steel, A36 steel plate has low raw material cost, stable performance, cost-effective, and is more economical than other steels. This makes it an ideal material that is both economical and reliable for most engineering projects.

Corrosion resistance: Although A36 is not as resistant to corrosion as stainless steel, the surface can be coated or galvanized to improve its durability.

A36 steel plate application field

Construction engineering: Due to the excellent mechanical properties and economy of A36 steel plate, A36 steel plate is often used to manufacture structural beams, columns, Bridges and other building support components.

Machinery manufacturing: A36 steel is also a common choice in the manufacture of machinery parts, frame structures and equipment bases.

Storage tanks: A36 steel can also be used to make storage tanks, the material is commonly used in the construction of high-pressure liquid and gas storage tanks. The sheet has good weldability and corrosion resistance, making it ideal for these applications.

Pressure vessels: A36 steel plates are also used in the manufacture of pressure vessels, such as boilers and heat exchangers. The material has good weldability and is suitable for high pressure applications. The steel plate also has good machinability and is easy to be processed into parts.

Conclusion

A36 steel plate has become one of the most widely used structural steels for its unique performance, economy and versatility. Whether in construction, agriculture, automotive production or any other application, A36 steel is the absolute material of choice. If handled properly, this steel plate can be a highly efficient material for a variety of projects.