ASTM A234 is a standard developed by the American Society for Materials and Testing (ASTM) for carbon steel and alloy steel pipe fittings used in medium to high temperature environments. It covers forged carbon and alloy steel fittings for seamless and welded construction, often including flanges, elbows, tees, caps, socket welds and other forms of fittings. The following details

ASTM A234 carbon steel pipe fittings:

1. Standard overview

Scope of application:

The ASTM A234 standard is applicable to carbon steel fittings used in piping systems in medium to high temperature environments. The accessory products cover all types of pipe joints and are designed to ensure structural integrity and secure sealing under high temperature and pressure conditions.

Product Category:

The standard specifies pipe fittings for industrial and energy transmission, such as

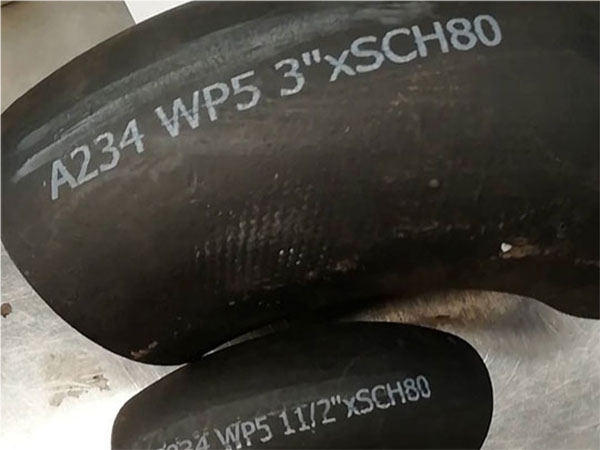

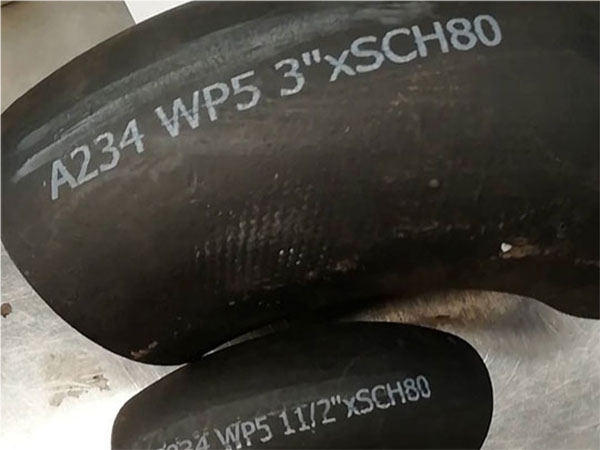

flanges, elbows, tees, caps, joints and socket welding fittings, which are required to meet stringent quality and performance standards during processing, welding and subsequent assembly. ASTM A234 common grades are WPB, WPC, WP5, WP9, WP11, WP22, WP91, etc. Among them, WPB and WPC are carbon steel, WP5, WP9, WP11, WP22 and WP91 are chromium molybdenum steel.

Conditions of Service:

ASTM A234 accessories are mainly used to withstand high temperatures (such as boilers, heat exchangers) and corresponding pressures to ensure that the product does not degrade or fail during long-term use under harsh conditions.

2. Material and chemical composition

Material selection

ASTM A234 fittings mainly use carbon steel, common fittings materials are killed steel, forgings, bars, sheets, seamless or fused welded pipe products, and add filler metal.

Chemical composition requirement

The standard has detailed provisions for different steel grades to ensure that the parts have mechanical properties and corrosion resistance that meet the design requirements.

3. Manufacturing process

Depending on the type of part and the specific requirements, ASTM A234 parts can be manufactured by forging, casting or welding processes.

Forging parts: Forging or forming operations may be performed by hammering, pressing, punching, extrusion, upsetting, rolling, bending, welding, machining, or by a combination of two or more of these operations.

Casting accessories: Using a mold, the liquid metal is cast into the mold, and it is cooled and solidified to obtain accessories or blanks. It is suitable for low and medium pressure occasions with complex shapes and not too harsh requirements.

Welding accessories: The use of resistance welding, submerged arc welding and other welding technology, the prefabricated materials are connected and formed to ensure that the mechanical properties of the welded joints are consistent with the overall product.

Heat treatment and finishing

After molding at high temperatures, the parts are cooled under appropriate conditions to a temperature below the critical range to prevent harmful defects caused by excessive cooling, but the cooling rate must not be faster than the cooling rate in still air. The specified heat treatment temperature is the metal (component) temperature. Reasonable heat treatment process can ensure that the accessories have good toughness and stability under medium and high temperature conditions.

Inspection and quality control

In the production process, ultrasonic, X-ray, magnetic powder and eddy current testing methods to ensure that product size, wall thickness, welding quality and internal defects are in line with ASTM A234 standard requirements, to ensure product consistency and long-term reliability.

4. Performance characteristics and advantages

The raw materials used to manufacture ASTM A234 fittings usually contain appropriate amounts of carbon, manganese, silicon and trace alloying elements (such as chromium, molybdenum, etc.), which can meet the requirements of creep resistance, high pressure resistance and corrosion resistance of the fittings under high temperature conditions.

High strength and pressure resistance: ASTM A234 fittings are manufactured using a unique process to provide high tensile and yield strength and can be used safely in medium temperature and high pressure environments.

Excellent high temperature and creep resistance: Designed for medium and high temperature services, this accessory can maintain stable performance in a thermal environment and prevent material fatigue or creep deformation due to prolonged high temperature action.

Excellent corrosion resistance: strictly controlled chemical composition and appropriate surface treatment process, so that the product can be in a certain corrosive media (such as sulfur, CO₂ containing media) long-term operation, extend the service life.

5. Application field

Oil and gas transportation and pipeline system: used in high temperature and high pressure transportation systems, such as oil fields, natural gas pipelines, etc.

Chemical and petrochemical plants: Ensure safe and efficient transmission in chemical reactions, heat exchange and other high temperature and pressure equipment.

Power station and boiler system: used for high-temperature steam or hot water pipe connection to ensure the system's tightness and pressure resistance.

Other industrial equipment: such as heat treatment equipment, storage tanks, pipeline support systems, etc., for applications with higher welding quality and overall performance requirements.

Conclusion

ASTM A234 carbon steel pipe fittings are essential components for medium to high temperature conveying systems. Strict chemical composition control, advanced forging, casting and welding processes, heat treatment and comprehensive quality testing ensure safe and stable operation in high temperature, high pressure and corrosive environments.