ASTM A672 Carbon steel pipe is manufactured according to ASTM A672 standards. ASTM A672 is the standard specification for electric fusion welded steel pipes for medium temperature and high voltage service, made from pressure vessel quality steel plates of several chemical compositions and strength grades, and made by electrofusion welding of filler metal. Industrial piping systems used primarily to transport liquids or gases such as oil, gas and water.

Specification and scope

Type:

ASTM A 672 GR. B55

ASTM A 672 GR. B60

ASTM A 672 GR. B65

ASTM A 672 GR.B70

ASTM A 672 GR.C55

ASTM A 672 GR.C60

ASTM A 672 GR.C65

ASTM A 672 GR.C70

Category name: 10, 11, 12, 13, 20, 21, 22, 23, 30, 31, 32, 33, 34, 40, 41, 42, 43, 50, 51, 52, 53, 60, 61, 62, 63, 70, 71, 72, 73.

Outer diameter: 12-64 inches.

Wall thickness: 2-60 mm.

SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS

Length: Single random length/double random length 5m-14m, 5.8m, 6m, 10m-12m, 12m or according to customer's actual requirements.

Manufacturing process

ASTM A672 carbon steel pipes are manufactured in two ways: seamless and welded.

Seamless pipe manufacturing: The use of perforation or drawing process production, hot rolling and cold drawing and other technical methods, so that the steel pipe has high accuracy and surface quality. The seamless manufacturing method ensures the integrity of the tube body and avoids weaknesses caused by welded joints.

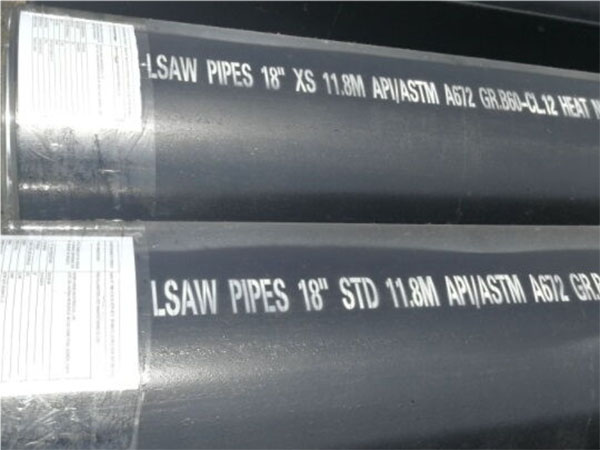

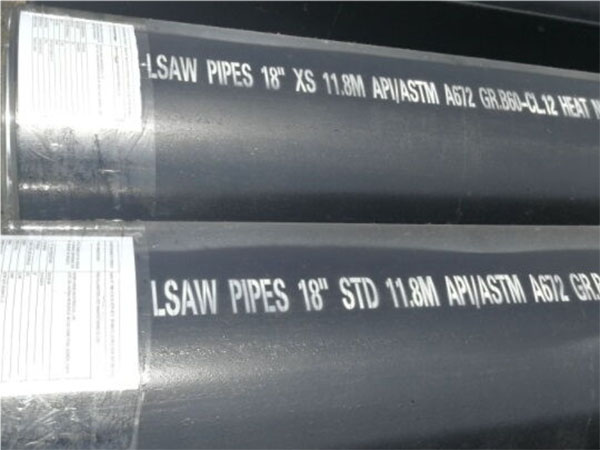

Welded pipe manufacturing: Some products may also be manufactured using

electric fusion welding (EFW), straight seam welding (LSAW) or spiral welding (SSAW) processes to meet different pressure and size requirements.

Surface treatment: The common surface treatment methods are black, paint, galvanized, coated with anti-corrosion coating (3PP/PE, FBE coating).

Test method: Mainly through eddy current testing, hydrostatic testing or ultrasonic testing, non-destructive testing and chemical and physical property inspection and other methods to ensure that each batch of products have no defects in the weld and overall structure, and can meet the long-term service requirements.

Performance characteristics

Excellent mechanical properties

After heat treatment and precision machining, ASTM A672 carbon steel pipe has high tensile strength, yield strength and good elongation, ensuring safe operation under high pressure and dynamic loads.

Good weldability and workability

The low carbon or low alloy steel composition ensures high operability and consistency in welding, cutting, bending and secondary processing of pipes for easy installation and maintenance on site.

Dimensional consistency and reliability

The use of advanced automated production equipment and strict dimensional testing, so that the outer diameter, inner diameter, wall thickness and other dimensions of the product stable and uniform, to ensure the system connection accuracy and sealing.

Corrosion resistance and protection measures

Although pure carbon steel itself is generally resistant to corrosion, ASTM A672 pipes can still have a long service life in a variety of industrial environments through internal and external anti-corrosion coatings, cathodic protection and other technologies.

Advantages of ASTM A672 Carbon Steel Piping

High economy: low carbon or low alloy steel material cost is low, processing technology is mature, suitable for large-scale production.

Efficient production: The use of automation equipment and strict quality control, to achieve high efficiency and product consistency.

Flexible application: Whether it is seamless pipe or welded pipe, it can be customized according to engineering requirements to meet the needs of different applications.

Good safety performance: After heat treatment and strict testing, the pipeline has excellent compression, fatigue and corrosion resistance, ensuring that it is safe and stable in long-term operation.

Conclusion

ASTM A672 carbon steel pipe as a pipe product in line with strict international standards, through advanced forming, heat treatment and testing processes, showing excellent mechanical properties, dimensional accuracy and reliability, widely used in industrial transportation, oil and gas pipelines and structural support and other fields.

Read more : ASTM A671 carbon steel pipe