Carbon steel mechanical pipe refers to a tubular product made of low carbon or low carbon alloy carbon steel as raw material through cold working process. Mechanical pipes are typically designed to meet specific end-use requirements, specifications, tolerances, and chemical properties. This allows for more specific performance uniformity throughout the tube compared to standard tubes.

Mechanical pipes usually have high accuracy and good surface quality, and their size, wall thickness and straightness are strictly controlled within narrow tolerances to meet the precision and consistency requirements of mechanical systems.

Several common classifications of carbon steel mechanical pipes

1. Hot-rolled resistance welded pipe (ERW) according to ASTM A513-1

ASTM A513 Type 1 is manufactured in outer diameter and wall thickness dimensions. This is the cheapest mechanical tube. It is made of mild steel and has relatively good cold working characteristics. DS, HSLA, galvanized, flash control and telescopic tubes are also available on special orders.

This steel pipe is graded 1010, 1020. There are three types of tube types: round tube, square tube and rectangular tube, and the length is generally 20' or 24' RL. The size range of different tube types is also different, the size range of round tube is 1/2" OD X.065 "W to 12" OD x 1/4" W, and the size range of square tube is 1/2" Sqr.x.065" W to 3" Sqr.x.120 "W, Rectangular tubes range in size from 1" x 1/2" x.065 W to 4" x 2" x.120" W. This kind of steel pipe is mainly used in furniture, storage shelves, machine parts, fences and so on.

2. Cold rolled Resistance Welding (ERW) according to ASTM A513-2

ASTM A513 Type 2 is manufactured in outer diameter and wall thickness dimensions. It is made of mild steel and has relatively good cold working characteristics. DS, HSLA, Galvanizing, flash control and retractable are also available on special orders.

This steel pipe is of grade 1008,1010. Also has round tube, square tube, rectangular tube three types of tube, the length of 20' or 24' RL. Round tube size range is 3/8" OD x.028 "W to 4" OD x.083" W, square tube outer diameter is 3/8" Sqr.x.028 "W to 2" Sqr.x.083" W, The outer diameter of the rectangular tube is 1" x 1/2" x.028" W to 2" x 1" x.083" W. This type of steel pipe is mainly used in environments requiring beautiful surfaces and lightweight materials. For example, display shelves, furniture, greenhouses, fitness equipment and so on.

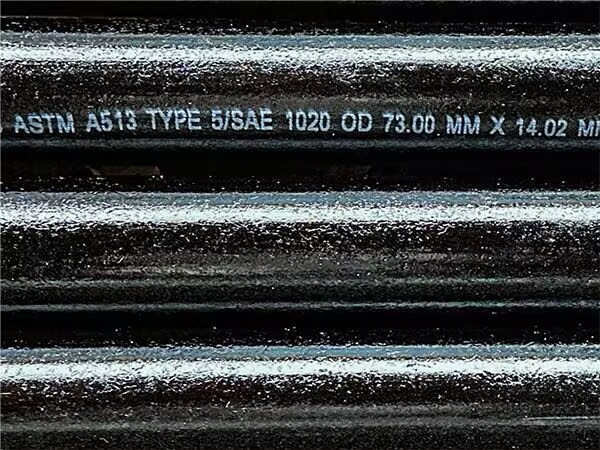

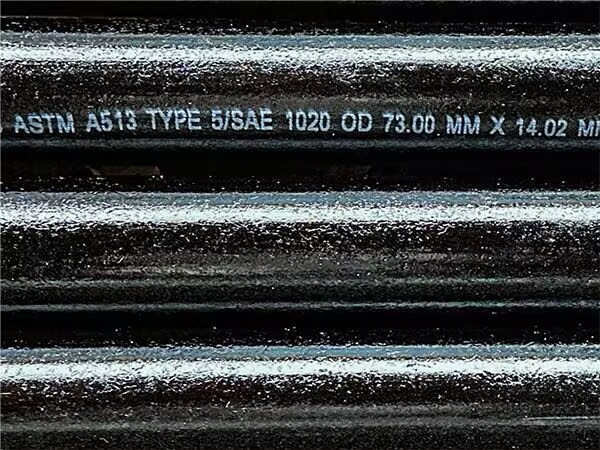

3. Drawn mandrel tube (DOM) according to ASTM A513-5

DOM tubing is usually produced in outside and inside diameter sizes. It is an electrically welded tube that has been re-drawn to remove bumps, control size and improve performance. DOM stands for "mandrel drawing" and the material is tested for weld firmness and straightness. The product has better finish and wall thickness uniformity than seamless tubes. DOM has excellent dimensional tolerances, concentricity, and mechanical properties.

This steel pipe is rated 1020, 1026, As Drawn or Stress Relieved Annealed (SRA). The length is generally 17'/24' RL and the size range is 1/4" OD X.035 "W to 12" OD x 5/8" W. Mainly used in automotive, home appliances and construction industries.

4. Cold-drawn and hot-worked seamless pipe according to

ASTM A519 standard

Hot-machined seamless pipes: Hot-machined pipes are produced according to outer diameter and wall thickness dimensions. Hot-machined tubes are less costly than cold-drawn seamless tubes and are an excellent material for applications that do not require the strict dimensional tolerances and surface finish offered by cold-drawn seamless tubes. If strict tolerances are required, the product is machined to precise specifications using machining. The dimensions range from 3" OD x 1/2" W to 20" OD x 3" W with a length of 17'/24' RL. It is mainly used in products requiring thicker walls and high strength materials, such as hydraulic cylinders, rollers and bushings.

Cold-drawn seamless pipe: Cold-drawn seamless pipe is usually drawn to the outer diameter and inner diameter dimensions. Cold-drawn seamless pipes have smaller dimensional tolerances, better surface finish and higher mechanical properties than the corresponding grade of hot-machined seamless pipes. The size range is 3/4" OD X.083 "W to 8" OD x 1" W and the length is 17'/24' RL. Mainly used in mechanical applications such as bushings, gaskets or other parts where mechanical properties are not specified or required.

Performance characteristics of carbon steel mechanical pipe

High precision dimensional control

The cold drawing process makes the carbon steel mechanical pipe have extremely high accuracy and consistency in the outer diameter, inner diameter and wall thickness, which is easy to match with other standard parts (such as joints, flanges, etc.), and achieve high interchangeability of the overall assembly of the system.

Good surface quality

After cold drawing and surface treatment, the pipe has a high finish, which facilitates further processing, assembly and welding, while reducing the risk of mechanical friction and deposition.

Excellent mechanical properties

The unique good toughness and ductility of low carbon steel make the cold-processed pipe maintain high tensile and yield strength at the same time, but also can withstand complex dynamic loads, suitable for high requirements of mechanical structures and transmission components.

Excellent weldability

Carbon steel mechanical pipe has good weldability, which is easy for manufacturers to assemble and repair on site, and ensure the stability of long-term operation.

Application field

Because of its high precision and good mechanical properties, carbon steel mechanical pipes are widely used in many fields, mainly including:

Machine building

Used in the production of automotive transmission shaft, hydraulic cylinder, precision instruments and equipment structural parts and connectors.

Industrial equipment

In the piping system of industrial automation and mechanical equipment, carbon steel mechanical pipes are used as key conveying pipes and structural support parts to ensure assembly accuracy and system operation efficiency.

Building structure

It is used to make pipe support, trim and transmission systems for the interior of buildings, while meeting aesthetic and safety requirements.

Other fields

Such as aerospace, railways and ships require high-precision pipes, carbon steel mechanical pipes may be used to achieve the precise connection and force transfer of the structure.

Concluison

Carbon steel mechanical pipe with its high precision, excellent surface quality, stable dimensional control and excellent mechanical properties, has become an important material in modern machinery and industrial manufacturing. Its excellent processability and weldability also give it obvious advantages in installation, maintenance and on-site repair, providing a reliable and economical solution for various high-precision engineering projects.