ASTM A53 B ERW carbon steel pipe is a resistance welded carbon steel pipe manufactured according to ASTM A53 standard, mainly used in the pipeline system to withstand general pressure and transport media. Commonly used in mechanical and pressure applications, it is also used in general purpose piping for the transport of steam, water, gas and air.

A53 Chemical composition of Grade B ERW carbon steel pipe (%, max)

Carbon: 0.30, Manganese: 1.20, Phosphorus: 0.05, sulfur: 0.045, copper: 0.40, nickel: 0.40, Chromium: 0.40, molybdenum: 0.15, Vanadium: 0.08.

Mechanical properties and related tests

Tensile strength (min) : 60000Ksi, yield strength (min) : 35000Ksi.

Bending test: For steel tubes NPS 2 [DN 50] or smaller, cold bending 90° around a cylindrical axis with a diameter 12 times the outer diameter of the steel tube is acceptable without any cracks. No bending test is required for double strength (XXS) pipes above NPS 1 1/4 [DN 32].

Flatness test: The first step is to test the ductility of the weld. The surface of the weld shall not be cracked or broken until the distance between the two plates is less than two-thirds of the outer diameter of the pipe.

Step 2: Test ductility away from the weld. Until the distance between the two plates is less than one-third of the outer diameter of the steel pipe but not less than five times the wall thickness of the steel pipe, the inner or outer surface far from the weld shall not be cracked or broken.

The third step is the integrity test. Continue flattening until the specimen block is broken or in contact with the tube wall without a stratified or incomplete weld.

Heat treatment: Welds of type E pipes must be heat treated at a temperature of at least 540°C [1000°F] to avoid the appearance of untempered martensite.

Hydraulic test: ASTM A53 B steel pipe held under hydrostatic pressure for at least 5 seconds.

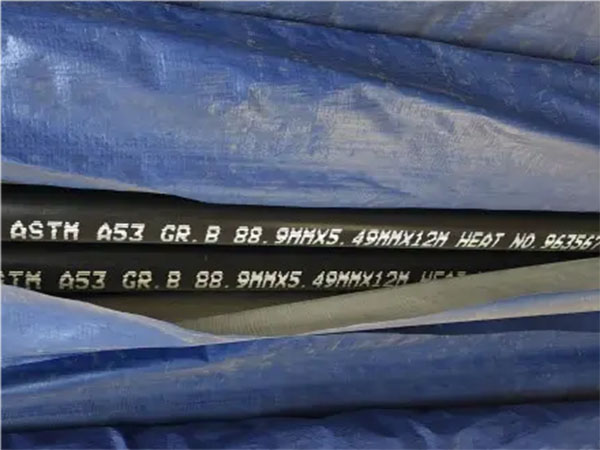

Dimensions: ASTM A53 B tubing sizes are generally NPS 1/8 to NPS 26 (DN6 to DN650), but other tubing sizes are available as long as all other requirements of ASTM A53 are met.

Classification: The A53 tubes are divided into three types (F, E, S) and two grades (A, B).

A53 Type F manufactured with furnace butt welds or may have continuous welds (Class A only)

A53 Type E with resistance welds ( A and B)

The A53 Type S is A seamless tube and is divided into A and B grades

A53 B ERW carbon steel pipe application

Oil and gas transmission: used as the main pipeline in oil fields and natural gas transmission systems to meet the requirements of fluid transmission under moderate pressure conditions.

Chemical pipeline: suitable for transporting various industrial chemical media to ensure safe and stable transportation.

Mechanical parts: can be used as machining, bearing group, processing machinery and other accessories.

Conclusion

ASTM A53 B ERW carbon steel pipe is an economical and practical pipe product, manufactured using advanced resistance welding technology, with high strength, pressure resistance and good weldability. The A53 B ERW carbon steel pipe is the ideal choice for engineering projects that require stable fluid transfer and focus on pipe cost control.