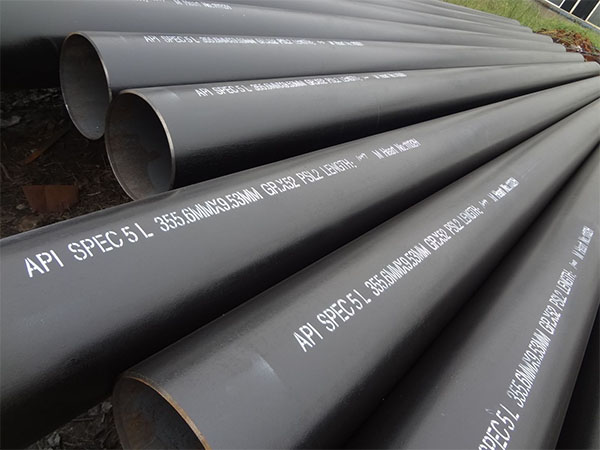

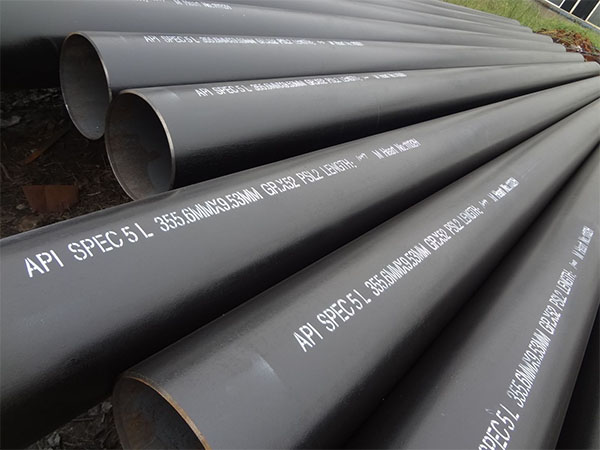

API 5L GR.B Carbon steel pipe is an American Petroleum Institute (API)5L carbon steel pipe, often used to transport oil, gas and water, with high strength, corrosion resistance and durability, suitable for use in high pressure and extreme environments.

Standard overview

API 5L: API 5L is a standard for oil and gas pipelines designed to regulate pipeline transportation systems within materials, equipment and offshore facilities in the oil, petrochemical and gas industries. This standard divides pipes into PSL1 (Product Specification Class 1) and PSL2 (Product Specification Class 2) by application area, with PSL1 being the standard quality class for pipeline pipes and PSL2 containing additional chemical, mechanical and testing requirements.

GR.B: GR.B indicates the level of the standard, which includes A25, A, B (and the following "X" level), X42, X46, X52, X56, X60, X65, X70, and X80. The two digits after the "X" indicate the minimum yield strength of the pipe produced in this grade.

Manufacturing process

API 5L Gr.B carbon steel tubes can be manufactured using either seamless tube manufacturing processes (perforation, drawing) or welding processes (e.g. ERW, LSAW, SSAW).

In the production process, heat treatment processes such as normalizing, annealing and tempering are often used to eliminate the residual stress generated after cold processing, optimize the grain structure, and ensure the stability and pressure resistance of the pipe in long-term service.

After the completion of production, it is also necessary to undergo strict chemical composition analysis, mechanical properties testing and non-destructive testing (such as ultrasonic testing, X-ray testing, etc.) to ensure that it meets the requirements of API 5L standards.

Central Steel has a full range of API seamless tubes, including PSL-1 and PSL-2 pipe lines.

Size (seamless) : 1/2 "NB-60" NB

Size (ERW) : 1/2 "NB-24" NB

Size (SAW/LSAW) : 16 "NB-100" NB

Available wall thickness:

Schedule 20-Schedule XXS (can be increased upon request) thickness up to 250 mm.

Chemical composition:

Carbon: 0.28% (max)

Manganese: 1.2% (max)

Phosphorus: 0.03% (max)

Sulfur: 0.03% (max)

Nickel: 0.5% (max)

Chromium: 0.5% (max)

Molybdenum: 0.15% (max)

Mechanical properties: tensile strength 60000Ksi (min), yield strength 35000Ksi (min).

Material grade

High temperature seamless pipe: ASTM A106 Gr.B/C, API 5L Gr.B, ASTM A53 Gr.B.

Heat exchange seamless pipe: ASTM A179.

Low temperature seamless pipe: ASTM A333 Class 3/6.

High yield seamless tube, API 5 l X42 / X46 / X52 X56 / X60 / X65 / X70 and X80 / PSL PSL - 1-2.

Atmospheric and low temperature EFW piping: ASTM A671 grade CC60/CC65/CC70.

High temperature EFW pipeline: ASTM A672 level B60 B65 / B70 C55 / C60 / C65 / C70.

High yield ERW/SAW pipe, API 5 l level X42 / X46 / X52 / X56 / X60 / X65 / X70 and X80 / PSL PSL - 1-2.

Application field

API 5L Gr.B carbon steel tubes can be used in a variety of applications:

Oil and gas transmission :API 5L GR.B Carbon steel pipes are commonly used for oil and gas transmission. Because of its high strength and good durability, it is more popular than other materials.

Water transport :API 5L GR.B carbon steel pipes are also used for water transport. Due to its corrosion resistance and durability, it is more popular than other materials.

Construction :API 5L GR.B carbon steel pipes are used in construction and infrastructure. It is commonly used in the construction of Bridges, tunnels and highways.

Manufacturing :API 5L GR.B carbon steel tubes are also used in the manufacture of industrial equipment. It is commonly used in the manufacture of boilers, heat exchangers and pressure vessels.

In summary, API 5L Gr.B carbon steel pipe is an economical pipe that meets international standards and is widely used in the energy industry to transport natural gas, oil and water. It has many characteristics suitable for use in high-stress environments, including high strength, corrosion resistance and durability. It is also used in other industries, such as construction and manufacturing.