The alloying elements of ASTM A234 WPB pipe fittings include carbon (C), manganese (Mn), phosphorus (P), sulfur (S), silicon (Si), etc. Its chemical composition follows specific range standards to ensure the balance of material properties.

|

Chemical composition |

C |

Si |

Mn |

S |

P |

Cr |

Cu |

Mo |

V |

Ni |

|

Content |

≤0.30% |

≥0.10% |

0.29-1.06 |

0.058 |

0.05 |

0.4 |

0.4 |

0.15 |

0.15 |

0.4 |

Mechanical properties of ASTM A234 WPB pipe fittings

The minimum tensile strength is approximately 415-585 mpa (60-85 ksi), the minimum yield strength is about 240MPa(32ksi), and the elongation is greater than 22%. These properties ensure that the pipe fittings can maintain stability and reliability even when facing complex working conditions.

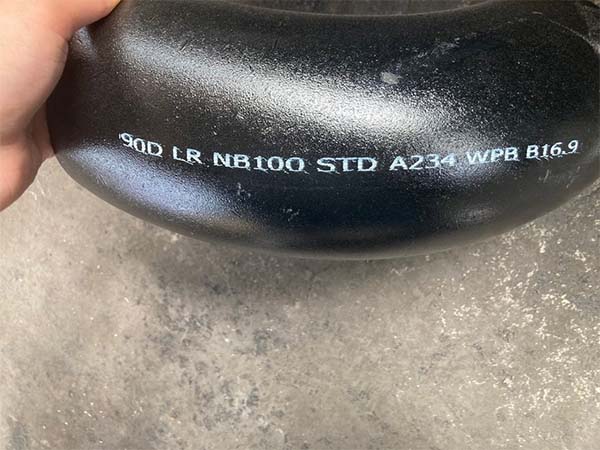

Manufacturing process of ASTM A234 WPB pipe fittings

The material of pipe fittings is usually deoxidized steel, which can come from forgings, pipes or plates, etc. The manufacturing methods are divided into forging or welding, and there are no castings.

Forging: By selecting appropriate raw materials, heating them to an appropriate temperature, and then placing them in a mold to be shaped into the required accessory form, a series of heat treatments are carried out to enhance the toughness of the pipe fittings. Finally, further adjust the dimensions and shapes of the pipe fittings.

Welding manufacturing: It is often achieved by bending and cutting welded pipes into shape, and is mainly used in the manufacturing of large pipe fittings.

Seamless manufacturing: It is made by bending and cutting seamless pipes. Its advantages lie in its complete structure, high strength, and no weld seams, making it suitable for high-temperature and high-pressure environments.

Heat treatment rules: When the heating temperature is relatively high, annealing, normalizing or tempering treatment is required. Some smaller-sized or stable-cooled pipe fittings may be exempted from treatment. Large-sized welded parts need to undergo post-welding heat treatment.

Performance characteristics of ASTM A234 WPB pipe fittings

1. High strength and hardness: Tensile strength ≥415 MPa, yield strength ≥240MPa, elongation ≥22%, ensuring it still has good toughness and load-bearing capacity in high-pressure and high-temperature environments. The upper hardness limit is 197 HBW, with a stable structure that can prevent brittle fracture caused by excessive hardness.

2. Strong high-temperature resistance: This material is suitable for medium to high-temperature steam and liquid medium systems, such as thermal power, petrochemical, and nuclear power plant pipeline systems. Its mechanical properties remain stable and reliable even in high-temperature environments.

3. Excellent processing and welding performance: With a carbon content of ≤0.30% and proper carbon equivalent control, it has outstanding welding performance, convenient weld formation, and effectively reduces the risk of cracks. This material is highly suitable for on-site installation and processing. It is easy to cut, machine, bend or weld, and has extremely high installation flexibility.

4. Economy: With carbon steel as the base material, it has a lower cost compared to stainless steel or alloy materials and offers high cost performance.

Application field

It is widely applied in the following fields

Petroleum and natural gas: It is used for transporting gases or liquid hydrocarbons and can operate stably in high-pressure and high-temperature environments.

Power plants and nuclear power: Widely adopted in high-temperature and high-pressure working conditions such as steam systems and condensate systems.

Chemical engineering and chemical Storage and Transportation: It features resistance to a variety of common chemical media, demonstrating excellent sealing performance and strength.

Marine and municipal engineering: It features corrosion resistance and fatigue resistance, and is convenient for welding and installation.

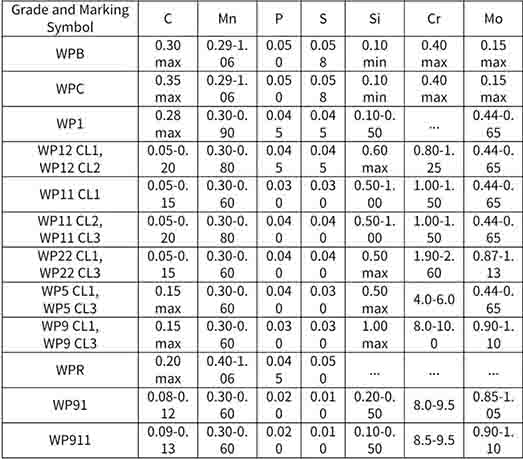

ASTM A234 WPB is the most commonly used grade in the ASTM A234 standard specification. Besides, it has many other grades, such as WPB, WPC, WP5, WP9, WP11, WP12, WP22, WP91, etc. The following are their differences in chemical composition:

Chemical composition

Summary

ASTM A234 WPB pipe fittings, with their excellent strength, ductility, pressure/temperature resistance and corrosion resistance, combined with good welding process characteristics and cost advantages, have been widely adopted in industrial fields such as petroleum, chemical engineering, power, shipping and municipal works, and can meet the strict requirements for safety and reliability under harsh working conditions.

Read more : ASME B16.5 flange dimensions