Butt welded elbow, as the most common pipe turning connection component, is widely used in industries such as petroleum, natural gas, chemical engineering, and power to achieve a smooth transition in the direction of the pipeline.

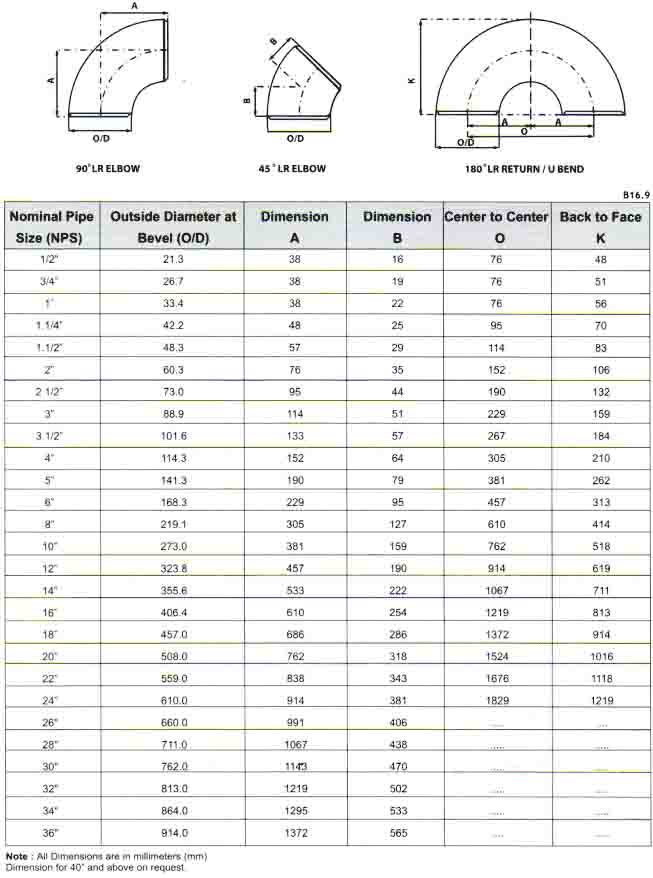

ASME B16.9 standard is one of the important specifications widely adopted in industrial piping systems, covering the dimensions and technical requirements of various forged butt-welded pipe fittings. This standard covers Butt weld elbows of NPS1/2to48 (i.e. DN15to1200), including long radius (LR), short radius (SR) and elbows of common angles such as 45°, 90°, 180°.

Material standards for welded pipe fittings

|

Material |

Standard |

|

Carbon steel |

ASTM A234 WPB / WPC |

|

Stainless steel |

A403 WP304/304L/304H、WP316/316L、WP317、WP310S、WP321、WP347、WP904L |

|

Low-temperature steel |

ASTM 420 WPL 3 / 6 / 9 |

|

Pipeline steel |

A860 WPHY 42 / 46 / 52 / 56 / 65 / 70 |

|

Alloy steel |

A234 WP5 / WP9 / WP11 / WP12 / WP22 /WP91 / WP92 |

Types of ASME B16.9 elbows

The types of elbows can be classified according to their bending angles and bending radii:

Classified by the Angle of bending:

45°elbow: It changes the direction of the pipe by 45°and is suitable for scenarios with moderate deflection.

90°elbow: It changes the direction of the pipe by 90°and is the most common and frequently used elbow, used for standard turning.

180°elbow: It changes the direction of the pipeline by 180°and reverses the 180°circulation for backflow. It is mostly used in heat exchange equipment.

Classified by the radius of bending:

Short radius elbow (SR) : The radius is equal to the nominal diameter (R=1D), and it is often used in environments with limited and confined space. This type of elbow has a relatively large pressure loss and is not frequently used.

Long radius elbow (LR) : The radius is 1.5 times the nominal diameter, resulting in less fluid resistance. Compared with short radius elbows, long radius elbows are more commonly used.

The size range of ASME B16.9 elbows

The advantages of butt-welded elbows

1. The weld seam has high strength and good overall performance

The butt welding installation method achieves full penetration welding (full-penetration weld), with the weld strength reaching or approaching the strength of the base material. The welded joint is equal to a part of the entire pipe, which can achieve overall force and uniform stress distribution.

2. Excellent sealing performance: The butt-weld joint has no gap and no gasket, which can prevent gasket leakage caused by aging and corrosion. It is suitable for high-purity, toxic, flammable or explosive hazardous fluids.

3. Low fluid resistance: The B16.9 elbow adopts a step-free arc inner cavity design, meeting the requirements of long radius (LR) and short radius (SR), reducing turbulence and pressure drop. Among them, the LR elbow (R=1.5D) has a lower pressure loss compared to the short radius, making it suitable for high-flow systems.

4. Strong pressure resistance and temperature resistance: ASME B16.9 elbows support various materials (carbon steel, alloy steel, stainless steel, etc.) and are suitable for high-temperature and high-pressure environments, such as power plants, petrochemicals, natural gas transportation and other high-demand working conditions. Compared with short-diameter connections or threaded connections, it allows for a higher working pressure rating and a longer service life.

Application field

ASME B16.9 elbows are widely used in:

Oil and gas pipeline

Chemical Engineering

Power station boiler

Food and pharmaceutical equipment

Water treatment system

Industries such as shipping and papermaking

Read more:Butt weld pipe fittings or ASME B16.5 flange dimensions