Stainless steel pipes are widely used in industries such as chemical engineering, petrochemicals, power, food, and medicine due to their excellent corrosion resistance and mechanical properties. In many application scenarios, welding is a key process for splicing and forming stainless steel pipes. However, as stainless steel materials are highly sensitive to temperature and oxidation, a slight mistake during welding may lead to defects such as intergranular corrosion, hot cracking or surface oxidation of the weld seam. The following is a detailed introduction to the key points of stainless steel pipe welding from three aspects: common welding methods, key operation skills and precautions, to help improve the welding quality and service life of the pipes.

Overview of Common Welding Methods

Tungsten inert gas welding (TIG)

Tungsten inert gas welding uses non-consumable tungsten electrodes and is protected by high-purity argon gas. Its advantages lie in stable arc, small heat-affected zone and beautiful weld formation, especially suitable for fine welding of thin-walled stainless steel pipes of 0.5mm or less. Due to the excellent protective effect of argon gas, the degree of oxidation of the weld seam is extremely low, and the post-weld treatment process is relatively simple. However, TIG welding has high technical requirements for welders, a relatively slow welding speed, and is not suitable for large quantities of thick and large workpieces.

Metal electrode gas shielded Welding (MIG)

MIG welding involves feeding the filler metal wire into the molten pool as the welding wire and then protecting the weld seam with gas (usually argon or a mixture of argon and helium). Its welding speed is relatively fast and the operation is relatively simple. It is suitable for stainless steel pipes with a thickness of 0.5-3mm. MIG welding can achieve continuous wire feeding, which is conducive to mass production. However, it has certain requirements for the flow rate of the shielding gas, the material of the welding wire and the size of the joint; otherwise, problems such as excessive spatter and rough weld surface may occur.

Manual Arc Welding (MMA

Manual arc welding uses wrapped electrodes for welding and does not require additional gas protection. For stainless steel pipes with a thickness of over 3mm, MMA welding equipment is relatively simple, low-cost and convenient for on-site construction. However, coated electrodes are prone to generating smoke and spatter during welding, and the oxidation degree of the weld seam is relatively high. Therefore, welders are required to be proficient in the electrode Angle, welding speed and current setting; otherwise, defects such as pores, cracks and weld beads are likely to occur.

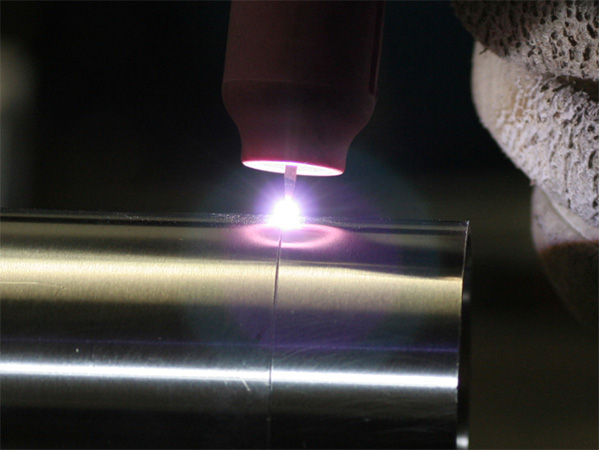

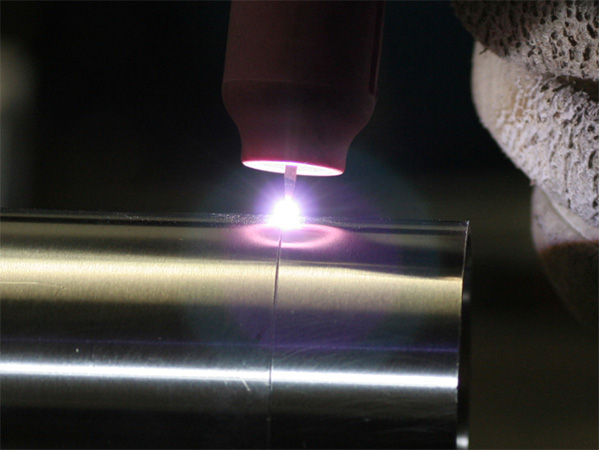

Plasma welding

Plasma welding has developed on the basis of tungsten inert gas welding, featuring a faster welding speed and a smaller heat-affected zone. Plasma nozzles can bundle gases to form plasma arcs with high energy density, and are suitable for stainless steel pipes with a thickness of 0.5 to 6mm. Due to the concentration of the plasma arc and the high-speed melting of the workpiece, high-quality and high-precision welds can be achieved, and it is easy to realize mechanized or automated production. The drawback is that the equipment cost is relatively high and it also has certain requirements for the technical level of the operators.

Preparations and key techniques before welding

For stainless steel pipes, the quality of welding is directly related to their performance and service life. Therefore, it is particularly important to do a good job in the preparatory work before welding.

1. Pre-welding cleaning:

Use acetone or a dedicated cleaning agent to thoroughly remove oil stains, fingerprints, rust layers and oxide scales from the pipe ends or pipe connections.

For rust spots with thick oxide scale or those that are difficult to remove on the surface, mechanical grinding can be carried out first with a stainless steel wire brush or grinding disc, and then further cleaned with a chemical degreaser.

2. Select welding parameters reasonably

Current and voltage: Select the appropriate current and voltage based on the thickness of the pipe wall, the welding position (flat welding, vertical welding, overhead welding), and the welding method. Generally, for thin-walled tubes (≤1mm), a lower current is selected to avoid being burned through. For thick-walled tubes (> 3mm), a higher current is required to ensure the penetration depth.

Welding wire diameter (MIG/TIG added wire) : For thin-walled tubes, 1.0-1.2mm welding wire is recommended, and for medium and thick-walled tubes, 1.2-1.6mm welding wire is selected to balance the deposition efficiency and weld quality.

Wire feeding speed and welding speed: Excessive speed will lead to uneven surfacing and protruding weld seams. If it is too slow, the weld seam will dissipate too much heat and become flat. Empirically, keep the welding speed matching the wire feeding rate and continuously fine-tune it according to the width of the weld bead and the shape of the molten pool.

3. Selection of protective gas

When welding stainless steel, argon gas with a purity of ≥99.99% should be used as the shielding gas. For MIG welding, a certain proportion of helium gas mixture can also be used to increase heat input and enhance penetration depth, but flow control is more crucial.

4. Arc length and welding torch Angle

For TIG welding, the tungsten electrode maintains an arc length of approximately 1 to 3mm with the workpiece. An arc that is too long will cause the protective gas flow to be disturbed and the argon gas coverage to be insufficient, resulting in oxidation. If the arc is too short, it is easy for molten droplets to splash and the tungsten electrode to stick to the workpiece.

The inclination Angle (working Angle) between the tungsten electrode and the workpiece is generally maintained at 80° - 85°, which is approximately 10° relative to the spatter Angle (forward Angle). A reasonable torch Angle helps stabilize the arc and ensures uniform weld formation.

When MIG welding, the inclination of the welding torch to the workpiece should also be controlled at 5° to 15° to facilitate the smooth transfer of molten droplets and reduce spatter.

5. Welding sequence and shrinkage deformation control

When welding stainless steel pipes, there are often long pipes and multiple branches. The welding sequence should be determined first. Generally, the middle section is welded first, followed by the contraction on both sides, and finally the branch pipes or accessories are welded to reduce the concentration of thermal stress.

For the circumferential seam welding of round pipes, double-sided symmetrical welding can be adopted. That is, first weld a point at a certain position, then rotate 180° and symmetrically weld a section. Alternating this process can effectively reduce deformation.

For multi-layer and multi-pass welding, the interlayer temperature should be controlled between each layer of welding, generally kept within 200-250℃, before proceeding to the next welding to prevent heat accumulation from causing intergranular corrosion and cracking.

Post-welding treatment and surface maintenance

Pickling and passivation: After welding, water or alkaline cleaning should be carried out first to remove obvious oil stains and welding slag. Subsequently, the weld seam and its surrounding area are chemically pickled with nitric acid or a mixed solution of sulfuric acid and nitric acid to remove oxides and secondary carbides. Finally, it is soaked or sprayed with an acid pickling passivator (containing trivalent chromium passivator) to restore a stable passivation film on the surface and further enhance the corrosion resistance.

Polishing and grinding: For pipelines with high appearance requirements, mechanical polishing can be carried out after pickling and passivation to make the weld surface smooth and clean, achieving a mirror-like or matte effect.

Use abrasive belts, polishing wheels, etc. to perform coarse, medium and fine polishing in sequence until there are no obvious weld marks on the surface. After polishing, conduct another ultrasonic cleaning or chemical cleaning to ensure that there are no residual polishing debris on the surface.

Summary

When welding stainless steel pipes, attention should not only be paid to the selection of welding methods, but also to the pre-welding preparation, precise control of welding parameters and angles, as well as post-welding pickling, passivation and surface treatment.