The

Schedule 40 pipe elbow is one of the most widely used pipe fittings in piping, industrial piping, and fluid transport systems. It features balanced wall thickness, reliable pressure resistance, and broad material compatibility, playing a crucial role in changing the direction of fluid flow while maintaining system integrity.

What is a Schedule 40 Pipe Elbow?

A Schedule 40 pipe elbow is a fitting used to change the direction of fluid flow, typically by 45° or 90°. The "Schedule 40" refers to the pipe wall thickness the elbow is matched with. Compared to Schedule 10 pipes,

Schedule 40 pipes have higher pressure resistance, making Schedule 40 pipe elbows suitable for medium-pressure fluid and gas systems.

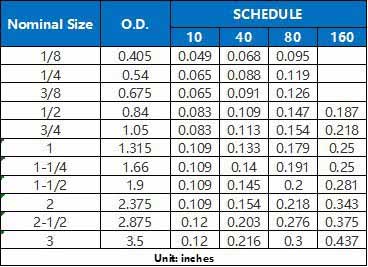

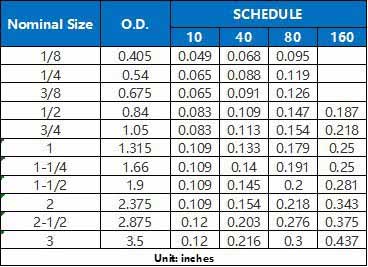

Schedule 40 Pipe Elbow Wall Thickness Comparison

What are the types of Schedule 40 pipe elbows?

The most common Schedule 40 elbows include:

1. 90° Schedule 40 Elbow

A 90° Schedule 40 elbow changes the direction of the pipe at a right angle. This type of elbow is most commonly used in water supply, drainage, and industrial piping systems.

2. 45° Schedule 40 Elbow

Compared to a 90° elbow, a 45° Schedule 40 elbow provides a smoother directional transition and reduces pressure loss.

3. Long Radius and Short Radius Schedule 40 Elbows

Long radius (LR) Schedule 40 elbows — reduce turbulence and friction losses.

Short radius (SR) Schedule 40 elbows — ideal for installations with limited space.

Materials for Schedule 40 Pipe Elbows

Schedule 40 elbows are available in various materials depending on the application environment:

Carbon Steel Schedule 40 Elbow

Stainless Steel Schedule 40 Elbow

PVC Schedule 40 Elbow

Galvanized Schedule 40 Elbow

Alloy Steel Schedule 40 Elbow

Each material has different corrosion resistance, pressure resistance, and cost characteristics.

Key Features of Schedule 40 Pipe Elbows

1. Balanced Wall Thickness

Schedule 40 elbows feature a medium wall thickness design, combining pressure resistance with economy, suitable for conveying common media such as water, gas, and oil.

2. Reliable Pressure Capacity

Due to its wall thickness matching that of SCH 40 pipes, SCH 40 pipe elbows perform stably under medium pressure conditions and are widely used in industrial and civil applications.

3. Wide Material Availability

Available materials include:

carbon steel Schedule 40 elbow

stainless steel Schedule 40 elbow

galvanized Schedule 40 elbow

PVC Schedule 40 elbow

4. Multiple Angle Options

Common angles include:

90 degree Schedule 40 elbow

45 degree Schedule 40 elbow

Meeting different piping direction conversion needs.

5. LR & SR Design

Long radius Schedule 40 elbow: Lower fluid resistance

Short radius Schedule 40 elbow: Saves installation space

Choose according to site space or fluid dynamic requirements.

Applications of 40° Elbows:

1. Industrial Piping: Widely used in fluid transport systems in petroleum, chemical, and power industries.

2. Water Supply and Drainage Systems: SCH 40 elbows are commonly used in building drainage systems.

3. HVAC Systems: Used in heating, ventilation, and air conditioning systems for changing the direction of hot and cold water or steam pipes.

4. Firefighting Pipelines: Carbon steel elbows are used in high-pressure firefighting pipelines.

5. Industrial Processing Plants: SCH 40 elbows are used in corrosion-resistant piping systems in laboratories or food processing plants.

Summary

A Schedule 40 pipe elbow is a dependable and versatile fitting essential for changing flow direction in many piping systems. With multiple angle options, material choices, and pressure capabilities, SCH 40 elbows offer a cost-effective and durable solution for a wide range of industrial and commercial projects.