Schedule 10 stainless steel pipe is a pipe standard with a relatively thin wall thickness and is widely used in situations where the pressure requirement is not high but there are requirements for corrosion resistance and weight. The following is a detailed introduction to the Schedule 10 stainless steel pipe:

What is schedule 10 stainless steel pipe?

"Schedule 10" (abbreviated as SCH 10) is one of the pipe wall thickness grades defined by the American Society of Standards (ASME), mainly used for the specifications of

stainless steel pipes. Compared with

Schedule 40 or

Schedule 80, Schedule 10 has a thinner wall thickness and is suitable for low-pressure conveying systems, structural supports, and weight-sensitive application scenarios. Common materials include 304 and 316 austenitic stainless steel, which have excellent corrosion resistance and weldability.

Examples of dimensions and wall thickness:

|

Nominal pipe diameter (NPS)

|

Outer diameter (OD)

|

Wall thickness(SCH 10)

|

|

1/2"

|

21.3 mm

|

2.11 mm

|

|

1"

|

33.4 mm

|

2.77 mm

|

|

2"

|

60.3 mm

|

2.77 mm

|

|

4"

|

114.3 mm

|

3.05 mm

|

|

6"

|

168.3 mm

|

3.40 mm

|

|

8"

|

219.1 mm

|

3.76 mm

|

|

10"

|

273.1 mm

|

4.19 mm

|

|

12"

|

323.9 mm

|

4.57 mm

|

According to the specifications of Schedule 10 (Sch 10) stainless steel pipes, if the nominal size of the pipe is 1 inch, its outer diameter is 33.4 millimeters, the corresponding wall thickness is 2.77 millimeters, and the theoretical weight per unit length (such as per meter) is approximately 2.11 kilograms.

Similarly, if the pipe size is 3 inches, the outer diameter is 88.9 millimeters, and the wall thickness of Sch 10 is 3.05 millimeters, its theoretical weight is approximately 6.05 kilograms per meter.

These dimensions ensure that the pipes have a relatively light weight while meeting the strength requirements, making them suitable for a variety of application needs.

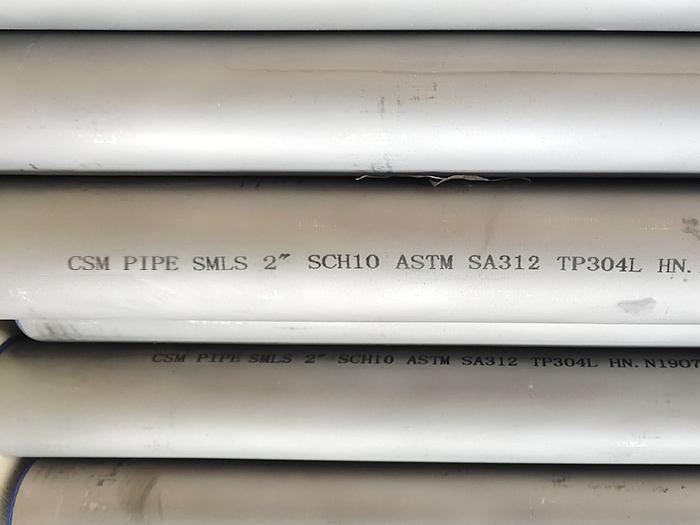

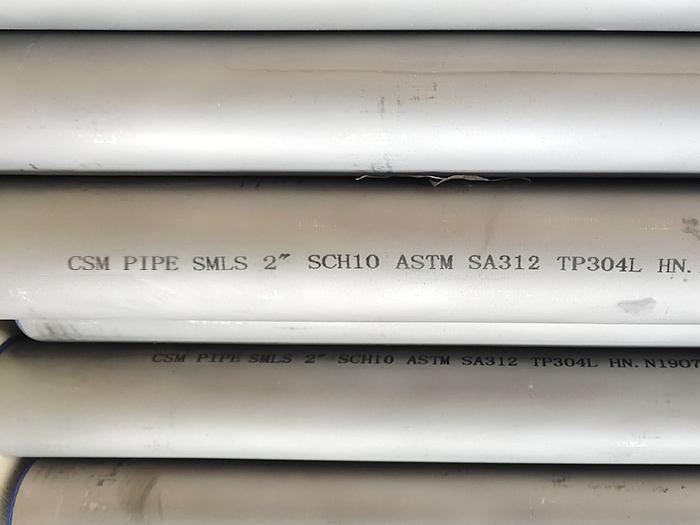

schedule 10 Common Materials and Standards of Stainless Steel Pipes

Material: 304 and 316 stainless steel are the two most common materials. 304 stainless steel has excellent corrosion resistance and formability, and is suitable for most environments. 316 stainless steel performs better in environments containing chlorides and is suitable for more demanding environments such as Marine and chemical treatments.

Standard: Schedule 10 stainless steel pipes usually comply with ASTM A312 and ASME B36.19M standards, ensuring their reliability in terms of size, mechanical properties and corrosion resistance.

Schedule 10 Pressure rating of stainless steel pipes

The Maximum Allowable Working Pressure (MAWP) of Schedule 10 stainless steel pipe depends on the nominal dimensions (NPS) and material of the pipe. The following are examples of pressure ratings for some dimensions (taking 304/316 stainless steel as an example) :

|

Nominal pipe diameter (NPS)

|

Outer diameter (OD)

|

Wall thickness (mm)

|

Maximum allowable working pressure (psi)

|

Maximum allowable working pressure (kPa)

|

|

1/2"

|

21.3 mm

|

2.11 mm

|

1310

|

9034

|

|

1"

|

33.4 mm

|

2.77 mm

|

1140

|

7852

|

|

2"

|

60.3 mm

|

2.77 mm

|

920

|

6341

|

|

4"

|

114.3 mm

|

3.05 mm

|

720

|

4964

|

|

6"

|

168.3 mm

|

3.40 mm

|

630

|

4344

|

|

8"

|

219.1 mm

|

3.76 mm

|

570

|

3930

|

|

10"

|

273.1 mm

|

4.19 mm

|

530

|

3651

|

|

12"

|

323.9 mm

|

4.57 mm

|

490

|

3378

|

These pressure grades indicate that Schedule 10 stainless steel pipes are suitable for medium and low pressure applications, such as fluid transportation, HVAC systems, and lightweight structural supports, etc. When choosing pipelines, it is necessary to ensure that the pressure rating of the selected pipeline meets the usage requirements based on the specific working pressure requirements and application environment.

Advantages and Limitations

Advantages:

It is light in weight and easy to install and transport

The cost is relatively low

Good corrosion resistance, suitable for a variety of environments

Easy to weld and process

Limitations:

Due to its thin wall thickness, it is not suitable for applications with high pressure or high mechanical load

In some structural applications, additional support or reinforcement may be required

Application field

Due to its thin wall thickness, light weight and good corrosion resistance, Schedule 10 stainless steel pipes are widely used in the following fields:

Food and beverage processing

The pharmaceutical and chemical industry

Low-pressure liquid and gas transportation

Building structure support

Cooling and air conditioning systems

Ships and Marine engineering