Schedule 40 stainless steel pipe (also known as Schedule 40S) is a type of stainless steel pipe in accordance with ASME/ANSI standards, which has both a fixed outer diameter and Schedule 40 wall thickness specifications. The common materials are 304 or 316. Its structure can withstand moderate pressure and is suitable for applications in gas, water, natural gas and general chemical pipelines.

Schedule (SCH) indicates the wall thickness grade of the steel pipe: the larger the number, the thicker the wall thickness. Schedule 40 is of medium wall thickness. Other common ones include Schedule 10 and Schedule 80. "40S" is the special marking of Schedule 40 in the stainless steel pipe system (specifically corresponding to ASME B36.19), maintaining the same thickness standard as Schedule 40 for carbon steel, and is usually used to indicate the stainless steel material.

Schedule 40 stainless steel pipe execution standards are as follows:

ASTM A312/A312M: Applicable to seamless and welded high-pressure pipes of austenitic stainless steel such as 304, 304L, 316, 316L, etc.

ASTM A358/A358M: Applicable to high-temperature resistant austenitic stainless steel seamless and welded pipes such as 347, 321, 347H, etc.

ASME B36.19M: Clearly stipulates the dimensions and wall thicknesses of Schedule 5S, 10S, 40S, 80S and other series of stainless steel pipes.

Commonly used materials include:

304/304L: Typical composition: 18%Cr - 8%Ni; It has good corrosion resistance and high economy.

316/316L: Typical components: 16%Cr - 10%Ni - 2%Mo; It has better resistance to pitting corrosion in a chloride environment.

321/347: Stabilization treatment, suitable for high-temperature working conditions, resistant to intergranular corrosion.

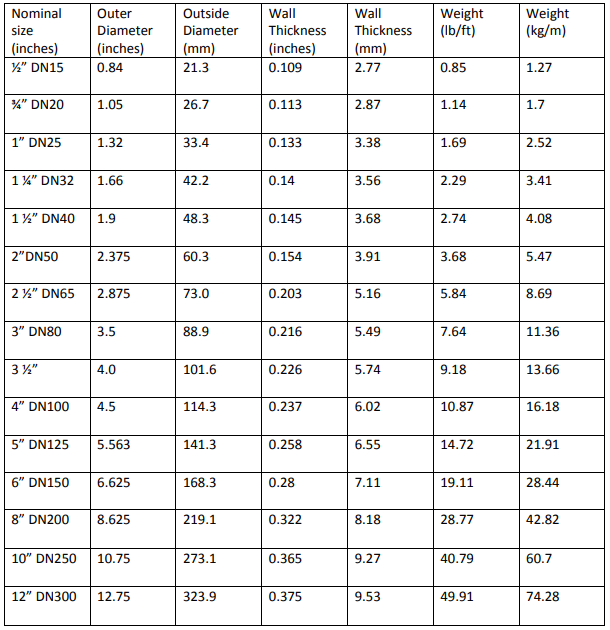

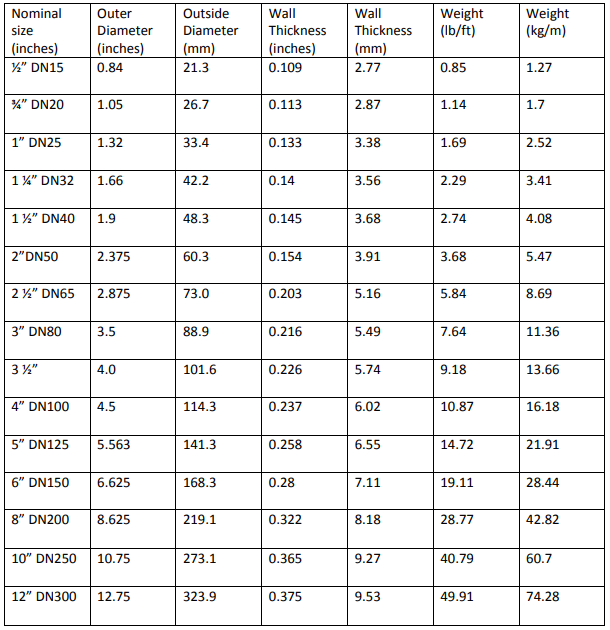

Schedule 40 stainless steel pipe specifications for dimensions, wall thickness and weight

Take common dimensions as an example to illustrate the specifications of Schedule 40 pipe (whether carbon steel or stainless steel, the outer diameter is the same) :

For NPS ≥ 4, the relevant DN = 25 times the number of NPS.

The wall thickness varies between NPS 12 and above, SCH 40 and STD, and between NPS 10 and above, 80 and XS.

Advantages of use and application scenarios

Strong corrosion resistance: Particularly suitable for damp or chemical environments. The 316 series is more suitable for salt water or chlorine-containing environments.

Moderate pressure-bearing capacity: The wall thickness is moderate, and the strength is higher than SCH10, making it suitable for medium-pressure pipeline systems. It can be used for the transportation of water, gas, steam and chemical media.

Easy welding and installation: Suitable for welded pipes and seamless pipes, and can be flexibly selected according to project cost and strength requirements.

It complies with the ASTM A312 / ASME SA312 material specifications and has reliable quality.

Key points for selection and precautions

Clarify the nominal size NPS and refer to the corresponding OD (outer diameter) and wall thickness. When choosing the appropriate material grade (such as 304 and 316L), it is necessary to comprehensively consider the chemical medium, the type of environmental corrosion and cost factors.

Consider the connection methods: including welding, threaded connection, flange connection or crimping. Threaded tubes are suitable for small-sized and low-pressure systems. For medium and large-sized pipelines, welding or flange connection is mostly adopted.

Pay attention to pressure and temperature limitations: Schedule 40 has a certain rated pressure, which needs to be selected according to specific working conditions; In higher pressure or high-temperature environments, Schedule 80 or other thick-walled specifications may need to be used. In terms of standards and certifications, confirm whether ASTM A312/A269 (seamless and welded) certification is required, and whether a third-party material report (MTC) is needed.

Read more:Schedule 40 steel pipe or ASTM A106 schedule 40 seamless carbon steel pipe