In the pipeline industry, we often see terms like "Schedule 40" and "Schedule 80". What exactly do they mean?

Schedule (Pipeline grade) represents the wall thickness series of the pipeline and is defined in accordance with the ASME B36.10M (carbon steel and alloy steel pipes) and B36.19M (stainless steel pipes) standards. Under the same nominal diameter (NPS), the Schedule 80 (also known as Extra Heavy, XS) pipe has a thicker wall thickness than the Schedule 40 (STD) pipe, resulting in a reduction in the inner diameter but maintaining the same outer diameter.

Size and weight

The wall thickness of Schedule 80 pipes ranges from 2.41 mm at ¼ "NPS to 32.79 mm at 24" NPS, and the corresponding weight per meter also increases exponentially.

According to ASME B36.10M, the outer diameter of the 2 "Schedule 80 pipe is 60.3mm, the wall thickness is 5.54mm, and the weight is approximately 7.48kg /m.

For the given NPS, the outer diameter of the Schedule80 tube is the same as that of tubes of other grades, but the wall thickness is significantly increased. For example, the wall thickness of 1 "Schedule 80 pipe is 0.179" (4.55 mm), while that of Schedule 40 pipe is 0.133 "(3.38 mm).

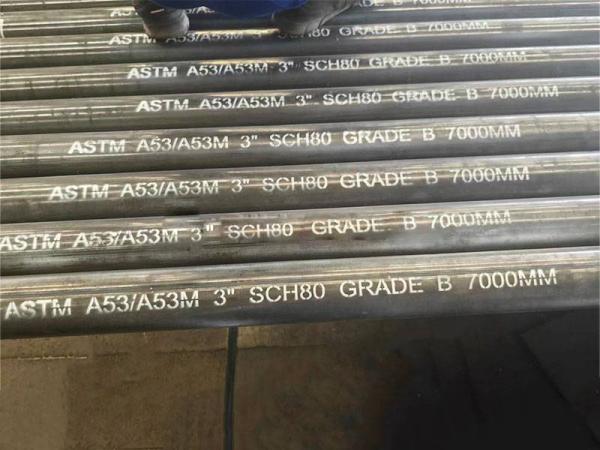

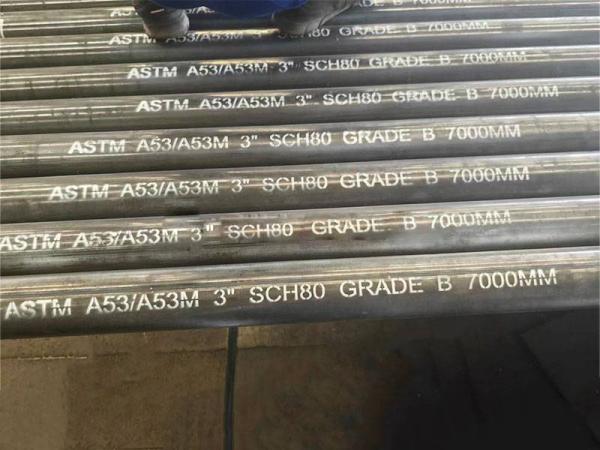

Manufacturing standard: Schedule 80 carbon steel pipes are usually made of seamless carbon steel that complies with

ASTM A106 Grade B (or

ASTM A53 Grade B, API 5L Grade B) specifications and can be used in high-temperature (≤425 °C) environments.

Seamless tubes with dimensions ≤ 1½ NPS can be hot-worked or cold-drawn. Cold-drawn tubes need normalizing treatment to relieve stress. Larger sizes are usually directly formed by hot working without the need for additional heat treatment.

Chemical composition

The chemical composition limit of ASTM A106 Grade B is as follows: C ≤ 0.30%, Mn 0.29-1.06%, P and S ≤ 0.035%, Si ≥ 0.10%, and contains trace elements such as Cu, Ni, Cr, Mo and V. The total residual elements do not exceed 1%.

Standards and Certifications

The dimensional grades follow ASME B36.10M (dimensions of carbon steel and alloy steel pipes) and B36.19M (stainless steel pipes); The material specifications are based on ASTM A106/A53 or API 5L; Welding shall comply with the requirements of ASME IX.

The application of process and power pipelines shall be designed, manufactured, inspected and tested in accordance with ASME B31.3 (process pipelines) or B31.1 (power pipelines) to ensure that the pressure design and quality documents meet the specifications.

Allowable pressure and temperature limits

At the ambient temperature (approximately 100 °F), the allowable pressure of the 1 "Schedule 80 pipe is approximately 630 psi. As the temperature rises, the strength of the pipe decreases, and the allowable pressure also drops accordingly.

Continuous use above 425 °C (800 °F) will cause carbides to transform into graphitization, significantly weakening mechanical properties and reducing available pressure. Therefore, such working conditions should be avoided.

Advantages and Limitations

Compared with the Schedule 40 pipe, the Schedule 80 pipe has higher mechanical strength and resistance to internal pressure deformation, but it is also heavier, more expensive, and the fluid transportation efficiency is reduced due to the decrease in inner diameter.

Thicker wall thicknesses often require the use of special pipe fittings and welding techniques, increasing construction costs and technical requirements.

In terms of maintenance, regular inspections of corrosion and wall thickness loss should be conducted, the graphitization tendency at high temperatures should be monitored, and the remaining service life and pipeline integrity should be evaluated through hydraulic or pneumatic tests.