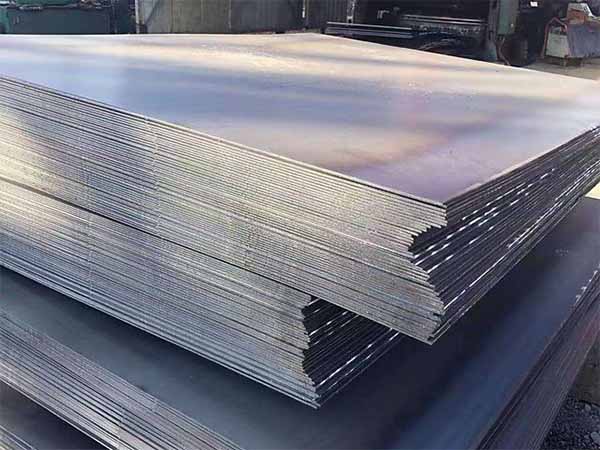

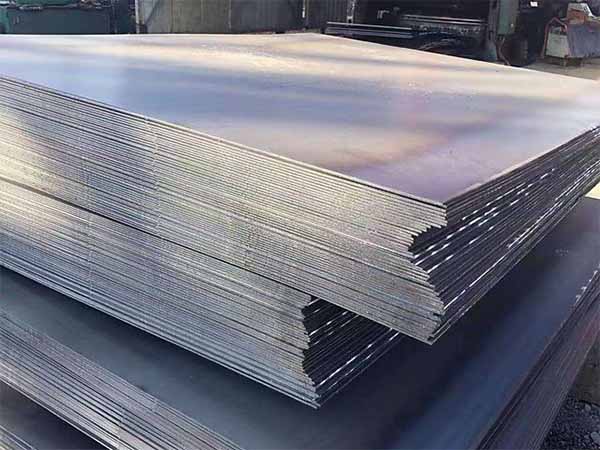

Hot-rolled steel plates possess outstanding performance, precision and surface quality. They are one of the most widely used steels in modern industry and are extensively applied in fields such as building structures, mechanical manufacturing, Bridges, shipbuilding and pressure vessels. This article will provide a detailed introduction to the production process of hot-rolled steel plates, helping you gain a deeper understanding of hot-rolled steel plates.

What is hot-rolled steel plate?

Hot-rolled steel plates refer to steel plates made by repeatedly rolling steel billets through rolling mills at high temperatures (usually above the recrystallization temperature). Compared with cold-rolled steel, the surface of hot-rolled steel plates is slightly rougher, but they have higher plasticity, weldability and strength, and are particularly suitable for structural components that need to withstand high pressure or complex processing.

An overview of the manufacturing process of hot-rolled steel plates

The production process of hot-rolled steel plates involves multiple key steps, including heating, rough rolling, finishing rolling and cooling. The process control of each link will affect the final performance and surface quality of the steel plate.

1. Heating stage

The first step of hot rolling is to heat the billet in a heating furnace to approximately 1200°C to achieve good plasticity and deformation properties. During the process, it is necessary to ensure that each billet is heated evenly. A heating temperature that is too high may lead to coarse grains, while one that is too low will increase the rolling resistance.

2. Rough rolling stage

The heated billets are sent into the roughing mill, where they are gradually thinned and elongated into preliminary slabs through multiple passes of rolling. At this stage, the thickness and width of the slab are mainly controlled to prepare for finishing rolling.

3. Finishing rolling stage

After rough rolling, the slabs will enter the finishing mill for high-precision rolling to ensure the thickness, flatness and surface quality of the finished steel plates. The temperature during the rolling process is usually around 900°C.

4. Cooling

After the finishing rolling is completed, the steel plate will be cooled down at a controlled rate through laminar flow cooling equipment to achieve the desired microstructure and properties. The cooling rate and uniformity have a significant impact on the strength and toughness of steel plates.

Quality control and inspection

Throughout the manufacturing process, Central Steel strictly implements multiple tests to ensure the stability of product quality:

• Dimensional inspection: The thickness, width and flatness of the plate meet the customer's requirements

• Surface inspection: No cracks, bubbles, inclusions or other defects

• Mechanical property testing: Strength and toughness are evaluated through tensile and impact tests

• Non-destructive testing (NDT) : Ultrasonic (UT) and X-ray (RT) are used to detect welding and internal defects

All products come with a Material Inspection Certificate (MTC) and can be certified by third-party inspection institutions (such as SGS, BV).

The key factors affecting the quality of hot-rolled steel plates

Heating temperature and uniformity: Determine the plasticity and microstructure of the steel plate;

Rolling speed and reduction rate: They affect the thickness tolerance and grain refinement degree of steel plates.

Cooling rate: It directly determines the mechanical properties of the steel plate.

Equipment accuracy and degree of automation: Ensure precise control of surface flatness and dimensions.

Read more : What is hot rolling process