A36 steel is one of the most widely used structural steels under the ASTM standard and is very common in fields such as construction, Bridges, and mechanical manufacturing. It has many excellent properties, such as good weldability, strong formability and low price. It is suitable for engineering and manufacturing fields with medium strength requirements but high demands on welding and economy.

Excellent welding performance

A36 steel is a typical general low-carbon structural steel. Its relatively low carbon content can significantly enhance the weldability of the steel, making it almost weldable by all welding methods.

Main chemical components:

|

Element

|

Content

|

|

Carbon, C

|

0.25 - 0.290 %

|

|

Copper, Cu

|

0.20 %

|

|

Iron, Fe

|

98.0 %

|

|

Manganese, Mn

|

1.03 %

|

|

Phosphorous, P

|

0.040 %

|

|

Silicon, Si

|

0.280 %

|

|

Sulfur, S

|

0.050 %

|

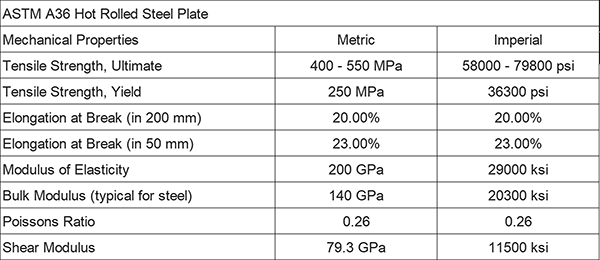

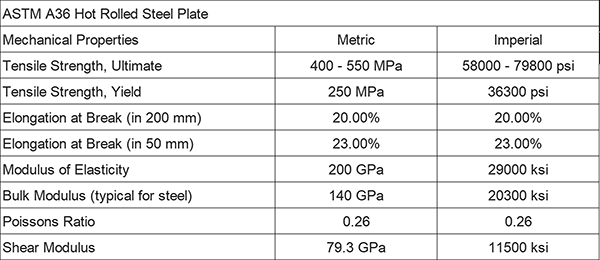

Mechanical properties

Mechanical properties mainly indicate its reliability in load-bearing and processing. Different projects have different requirements for performance. The following are the mechanical properties of A36 steel plates:

The yield strength of A36 steel is usually above 250 MPa, and its tensile strength is between 400 and 550 MPa, indicating a medium strength level. More importantly, its elongation is generally around 20%, and it has good ductility and toughness. This enables A36 steel to effectively bear loads in building structures while maintaining stability during construction and use.

Compared with high-strength steel, the strength of A36 steel is not the highest, but its comprehensive performance is very balanced and it is more suitable for common engineering scenarios.

How is the corrosion resistance of A36 steel?

Unlike stainless steel, A36 steel does not have natural corrosion resistance. In damp or Marine environments, exposed A36 steel is prone to rust. Therefore, in damp and other harsh environments, it is usually necessary to carry out anti-corrosion treatment. Common anti-corrosion treatments include

Spraying anti-corrosion paint (Painting/Coating) : Apply paint or epoxy coating on the surface of steel to isolate air and moisture and slow down oxidation reactions.

Hot-dip Galvanizing: A36 steel is immersed in high-temperature molten zinc liquid to form a dense zinc layer on the surface. The zinc coating not only isolates corrosive media but also protects the base steel through the "sacrificial anode effect".

Cold Galvanizing (Electro-galvanizing/Cold Galvanizing) : A thin layer of zinc is formed on the surface of steel through electrolysis.

Thermal Spray Coating: It involves heating and melting metals (such as zinc and aluminum) with flames or electric arcs and spraying them onto the surface of steel to form a protective layer.

Good economic benefits

The choice of materials often depends not only on performance but also on cost. A36 steel is relatively inexpensive due to its large output and abundant supply. For large-scale engineering projects, the use of A36 steel can significantly reduce overall costs without sacrificing safety and reliability. This is also an important reason why it has been able to maintain its mainstream position in the market for a long time.

Summary

A36 steel is a typical low-carbon structural steel that combines uniform strength, good weldability, excellent processing performance and economy. Although its corrosion resistance is limited, through reasonable protective measures, it can still demonstrate strong practical value in various engineering fields.

Read more : What is the meaning of A36 plates