Carbon steel and mild steel are two of the most widely used materials. While mild steel is technically a type of carbon steel, the differences in carbon content result in noticeable variations in strength, hardness, weldability, and application scope. Understanding these differences is helpful for knowing how to choose the best materials for projects.

What Defines Carbon Steel and Mild Steel?

Carbon steel refers to steel that primarily relies on carbon as the main alloying element. Depending on the carbon percentage, it can be categorized into low, medium, and high carbon steel.

Mild steel, commonly known as low-carbon steel, typically contains 0.05%–0.25% carbon, offering excellent ductility and weldability.

Core Differences: Strength vs. Workability

The most significant difference lies in strength and processing flexibility.

Carbon steel with higher carbon content delivers improved hardness and tensile strength, ideal for wear-resistant components.

Mild steel, in contrast, is softer and easier to form or machine, making it suitable for large-scale fabrication and structural work.

|

Feature |

Carbon Steel |

Mild Steel |

|

Carbon content |

Medium to high |

Low |

|

Strength & hardness |

Higher |

Lower |

|

Weldability |

Lower |

Excellent |

|

Machinability |

Medium to difficult |

Easy |

|

Typical cost |

Higher due to processing |

More economical |

Corrosion Resistance and Protection

Both materials are prone to rust without surface protection. For enhanced durability, industries commonly apply painting, galvanizing, epoxy coatings, or powder coatings. In corrosive environments, correct surface treatment plays a decisive role in lifespan and maintenance frequency.

Where Are They Used?

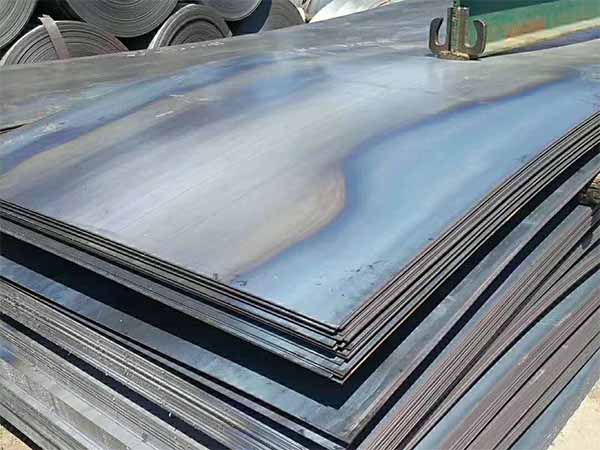

Mild steel’s balance of strength, formability, and affordability makes it a top choice for construction structures, pipelines, automotive frames, and machine parts.

Carbon steel, particularly with higher carbon content, is widely used in cutting tools, wear plates, high-strength bolts, pressure components, and heavy machinery where performance requirements are more demanding.

Cost comparison

Mild steel offers a lower overall cost, especially when machining and welding are considered. However, when long-term strength or abrasion resistance is required, upgrading to higher-carbon steel often becomes a more cost-effective solution over product lifetime.

How to Choose the Right Steel for Your Project

Need strong structural support with easy fabrication → Mild steel

Need wear resistance and high mechanical strength → Carbon steel with higher carbon content

Need welding and forming efficiency → Mild steel

Need hardness and durability under pressure → Carbon steel

As industries demand stronger, lighter, and more efficient materials, carbon steel and mild steel will continue to evolve through improved alloying technology and advanced anti-corrosion solutions. Choosing the proper grade remains essential for reducing costs and improving service life in modern engineering applications.

In summary, although mild steel is technically carbon steel, its lower carbon content creates distinct performance advantages in welding and fabrication, while higher-carbon steel excels in durability and wear resistance. Understanding these differences ensures smarter material selection and better project results.