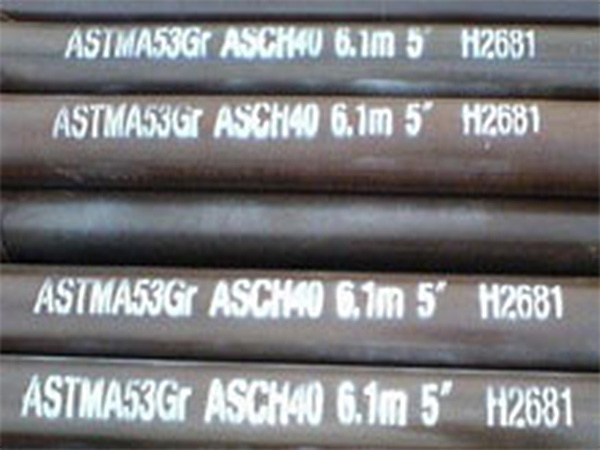

ASTM A53/A53M is the standard for carbon steel pipes of the American Society for Testing and Materials (ASTM), covering two major categories: Seamless and welded (including resistance welding ERW and furnace welding SAW). It is further divided into two grades (Grade A, Grade B) and three manufacturing types (Type F, Type E, Type S). The following focuses on the main features of Grade A.

A53 Grade A pipes are mainly used in pipe systems with relatively low strength requirements under medium and low pressure, such as water and gas transportation, fire protection systems, mechanical supports, structural supports, and other occasions.

Main chemical components (Grade A)

|

Element |

Type S |

Type E |

Type F |

|

C |

0.25% |

0.25% |

0.25% |

|

Mn |

0.95% |

0.95% |

1.20% |

|

P |

0.05% |

0.05% |

0.05% |

|

S |

0.045% |

0.045% |

0.045% |

|

Cu、Ni、Cr |

0.40% |

|

|

|

Mo |

0.15% |

|

|

|

V |

0.08% |

|

|

Mechanical properties: The minimum tensile strength is 48,000 psi. The minimum yield strength is 30,000 psi.

Dimensional tolerances and testing requirements

Wall thickness tolerance: At no point shall the wall thickness be less than 12.5% less than the nominal wall thickness.

Weight tolerance: ± 10%. ASTM A53 Grade A pipes

ASTM A53/A53M is the standard for carbon steel pipes of the American Society for Testing and Materials (ASTM), covering two major categories: Seamless and welded (including resistance welding ERW and furnace welding SAW). It is further divided into two grades (Grade A, Grade B) and three manufacturing types (Type F, Type E, Type S). The following focuses on the main features of Grade A.

A53 Grade A pipes are mainly used in pipe systems with relatively low strength requirements under medium and low pressure, such as water and gas transportation, fire protection systems, mechanical supports, structural supports, and other occasions.

Main chemical components (Grade A)

Outer diameter tolerance: NPS ≤ 1½ : ±1/64 "/ - 1/64"; NPS ≥ 2: ±1%.

Pressure test: NPS ≤ 3 minimum 2 500 psi, NPS > 3 minimum 2 800 psi, held for at least 5 seconds.

Mechanical testing

Type E NPS 8 and above require transverse tensile test;

Bending test is required for NPS 2 and below;

≥ NPS 2 requires flattening test, XXS is not applicable.

Non-destructive testing: such as ultrasonic/electromagnetic flaw detection, especially when the strength of the weld seam is no less than that of the base material.

Performance characteristics and applications

Good formability: Grade A is suitable for cold bending, close coil curling and flanging, especially Type S and E.

Good weldability: Various welding methods such as arc welding and gas welding can be adopted.

Pressure resistance capacity: Through water pressure testing during manufacturing, it is suitable for the transportation of low-pressure steam, water and gas.

Strong corrosion resistance: After hot-dip galvanizing, it has good environmental weather resistance.

Cost-effectiveness: Suitable for large-scale pipeline systems, it offers good value for money.

Typical applications include water/gas pipelines, structural pipes (lightweight brackets), HVAC systems, oil/chemical pipelines, and Marine engineering, etc.

ASTM A53 Pipe Selection Tips

When purchasing ASTM A53 pipes for a specific project or application, it is essential to comprehensively consider the following four aspects to ensure that the pipe performance and service life meet the project requirements:

Determine the required type

Type S (Seamless Pipe) : Suitable for high-strength applications without weld interference.

Type E (Resistance Welded Pipe) : Low cost, suitable for normal pressure and medium and low pressure conveying systems; If better formability is required, cold expansion treated pipes can be selected.

Type F (furnace Welded pipe) : The weld seam is smooth, suitable for longer normal temperature transportation, but its pressure resistance grade is slightly lower than that of Type S.

Evaluate the grade of materials

Grade A: Low yield strength (≈205 MPa), good ductility, easy to bend and form, suitable for low-pressure, cold bending or flanging applications.

Grade B: It has higher strength (yield ≈240 MPa, tensile strength ≈415 MPa), excellent compressive resistance, and is often used for high-pressure pipelines and structural supports.

Consider surface treatment or coating

Hot-dip galvanizing: It can effectively prevent rust in outdoor or humid environments and extend the service life of pipelines.

Epoxy coating/epoxy powder spraying: Suitable for working conditions with higher requirements for corrosion resistance, such as chemical industry and sewage treatment.

Organic coatings: lightweight and easy to apply, but their weather resistance is not as good as that of metal coatings.

Check the dimensions and tolerances

Outer diameter (OD) and wall thickness: Strictly correspond to the design requirements to avoid pressure instability due to overly thin pipe walls or increased costs and weight due to overly thick ones.

Length specification: Select the appropriate standard length or custom length based on the installation method (straight section, multi-section splicing) and transportation convenience.

Tolerance range: Ensure that the selected pipe complies with ASTM A53 tolerance standards for outer diameter, wall thickness and straightness to avoid affecting the assembly of joints or brackets due to dimensional deviations.

Read more:ASTM A53 Grade A vs Grade B pipes