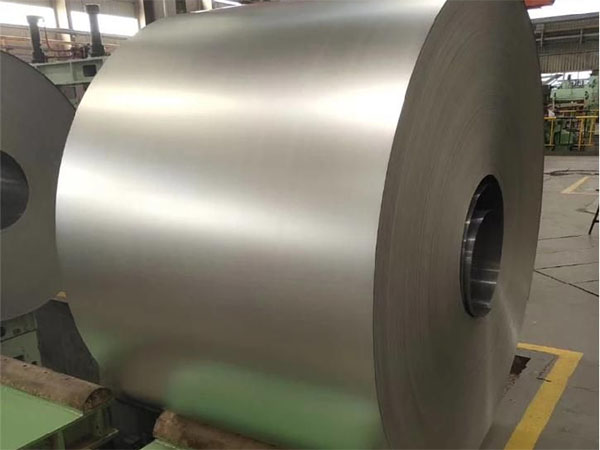

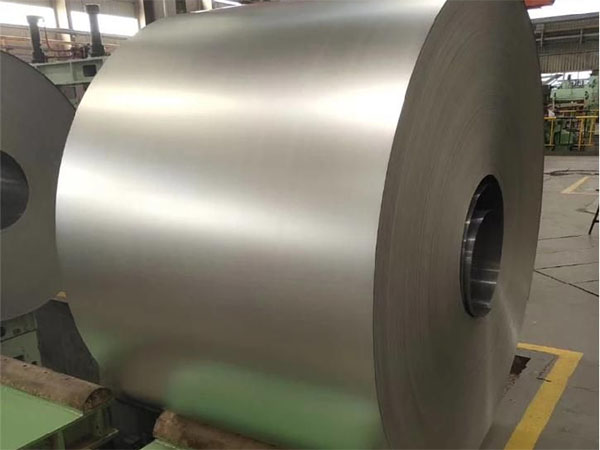

In the steel industry,

cold rolling is a crucial finishing process. It refers to a metal processing method in which hot-rolled steel is compressed at room temperature through one or more pairs of rolls to reduce its thickness, make its dimensions more precise and its surface smoother. Cold-rolled products are not only widely used in the manufacturing of automobiles, home appliances, construction and machinery, but also hold an important position in the fields of high-precision electronics and stainless steel products.

Cold rolling process flow

Cold rolling typically uses hot-rolled coils as raw materials. Through steps such as pickling to remove surface oxide scale, applying lubricants, multiple cold rolling thinning processes, intermediate annealing, skin-pass, surface treatment or slitting, high-strength, high-precision, and smoothed cold-rolled steel plates or steel strips are ultimately obtained.

In actual production, to prevent materials from losing their plasticity due to work hardening, annealing is often required during the cold rolling process to restore ductility and refine grains.

The characteristics and advantages of cold rolling

High dimensional accuracy: The thickness of cold-rolled products is precisely controlled, with errors that can be kept within an extremely small range.

Excellent surface quality: Compared with hot-rolled steel plates, cold-rolled steel plates have a smoother and brighter surface, which is conducive to subsequent galvanizing, spraying or coating treatments.

Mechanical property improvement: Cold rolling causes work hardening in steel, significantly enhancing its yield strength and hardness, making it suitable for applications that require higher strength.

Special treatment is possible: After annealing, tempering or surface coating processes, cold-rolled products can balance strength and ductility, meeting complex forming requirements such as deep drawing and bending.

The difference between cold rolling and hot rolling

Temperature: Cold rolling is carried out at room temperature, while hot rolling is conducted at high temperatures (above the recrystallization temperature).

Surface quality: The cold-rolled surface is smooth and clean, while the hot-rolled surface has an oxide scale.

Precision: The dimensional accuracy of cold rolling is much higher than that of hot rolling.

Mechanical properties: Cold-rolled steel has higher strength, but its plasticity relatively decreases. Hot-rolled steel has good ductility but relatively low strength.

Therefore, hot rolling is more suitable for large structural components with lower precision requirements, while cold rolling is the preferred choice for high-end manufacturing with higher demands on precision and surface.

Typical applications of cold-rolled steel

Automobile manufacturing: body panels, reinforcing plates.

Home appliance industry: boards for the shells of refrigerators, washing machines, air conditioners, etc.

Construction and Machinery: Light structural components, precision pipes.

Stainless steel products: kitchen equipment, medical devices, electronic casings.

Electrical steel: Cold-rolled silicon steel sheets, used in transformer and motor cores.

Summary

The cold rolling process is an indispensable link in the deep processing chain of steel. It provides high value-added materials for downstream industries through precise thickness control, excellent surface quality and adjustable mechanical properties. Whether in automotive lightweighting, home appliance appearance parts, or in high-end stainless steel products and electrical steel fields, cold-rolled steel plays an irreplaceable role.