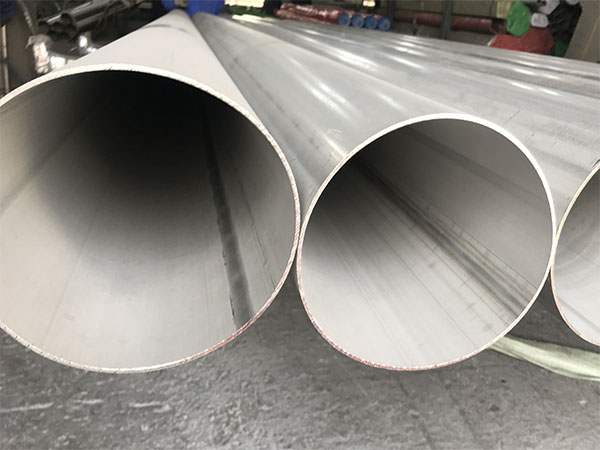

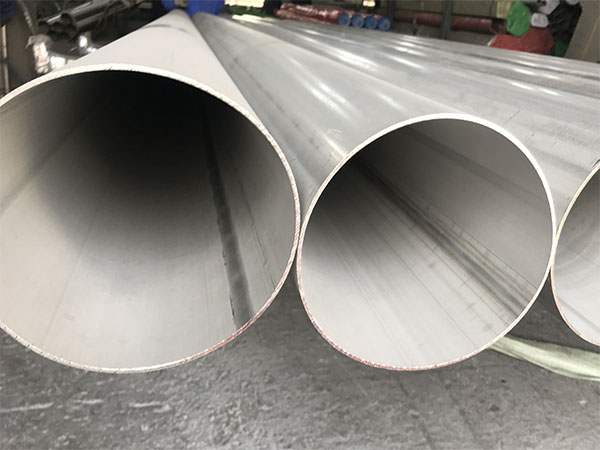

Stainless steel welded pipes are made by rolling and butt stainless steel strips or plates and then welding them along the pipe axis to form round or square or rectangular pipes.

Central Steel is an advanced manufacturer, supplier and exporter of stainless steel pipes in China. Our stainless steel welded pipes are manufactured using advanced welding techniques to ensure high precision, high durability and excellent corrosion resistance.

The mainstream types of manufacturing:

Straight seam steel pipe: It is welded in a straight line along the pipe axis, and the weld seam appears as a straight line. The types include ERW and LSAW.

Spiral steel pipe: The weld seam is in a spiral shape, and the types include SSAW.

The methods and processes of welding

Automatic welding: A method of welding through mechanical equipment, mainly using submerged arc welding (SAW), plasma welding (PAW), etc., which is highly efficient and ensures good weld quality.

Manual welding: Tungsten inert gas welding (TIG) is usually used, and a mixed shielding gas of CO₂+Ar is used during filling and cover welding.

Post-treatment of weld seams: removal of welding slag, grinding, and passivation to maintain color, effectively reducing the corrosion tendency near the weld seams.

The types and characteristics of materials

Commonly used stainless steel materials include austenitic (such as 304/304L, 316/316L), ferritic, martensitic, duplex, etc.

Chemical composition: Typical examples are 18-20% chromium and 8-12% nickel (taking 304 as an example). It has a higher content of 316/Mo and is used in highly corrosive environments.

Performance characteristics:

It has strong corrosion resistance and can cope with acidic, alkaline and chloride environments.

It has the performance of high strength, high pressure resistance and the ability to withstand cold and hot cycles.

Good weldability and low-temperature toughness (especially for the austenitic type);

The surface is smooth and beautiful, and easy to clean.

Lightweight, environmentally friendly and recyclable.

Standard specification

Common implementation standards: ASTM A312/A554, EN 10296-2, GB/T 12771, etc.

Wall thickness standards are classified according to SCH pressure grades, such as SCH40, SCH80, SCH160, and XXS.

Purpose

Medium and low pressure fluid transmission: such as water, gas, oil, air, steam, etc. for general purposes.

Decoration projects: stair railings, curtain walls, railings, etc., which are both aesthetically pleasing and practical.

Industrial equipment: Used in chemical pipelines, heat exchangers, boilers, pressure vessels, etc.

Special industrial applications: such as Marine structures, aviation equipment, electrical conduit, automotive exhaust, etc.

Key points of welding technology

The quality requirements for weld seams are high: If straight seams or spiral seams are adopted, it is necessary to ensure that there are no cracks or holes to guarantee sealing.

Common welding methods: TIG (argon arc welding), MIG/MAG, submerged arc welding, etc.

Nitrogen/argon gas is required for root purging to prevent post-weld oxidation and affect corrosion resistance.

Material stability: Some materials, such as 316, are prone to intergranular corrosion. Low-carbon L series or stabilization treatment are safer.

Wall thickness economy: The cost of thick-walled welded pipes increases, making them suitable for low-pressure and medium to small diameter scenarios.

Summary

Stainless steel welded pipes have significant advantages in functionality, economy and aesthetics. By choosing the appropriate material (such as 304, 316, 316L, 347, etc.), welding method and specification based on the usage environment, a pipe solution with stable performance, high cost and long service life can be obtained.