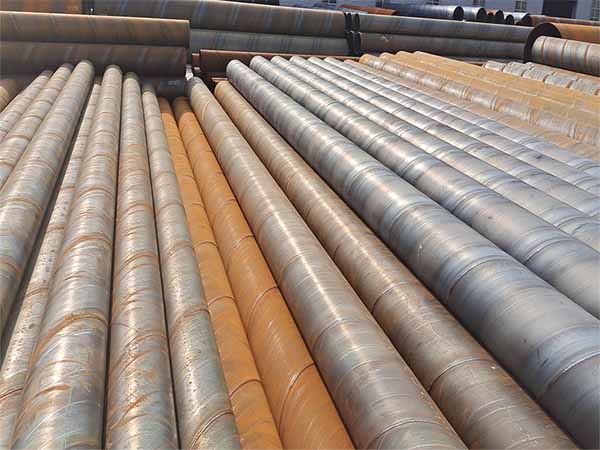

Spiral welded pipe specifications play a crucial role in determining whether a pipe is suitable for a structural, foundation, or piping application. This guide explains spiral welded pipe specifications from both practical and engineering perspectives.

1. What are Spiral Welded Pipe Specifications?

Spiral welded pipe specifications refer to the dimensional and technical parameters that define how the pipe is manufactured and applied. These parameters typically include:

Outer Diameter

Wall Thickness

Length

Applicable Standards and Steel Grades

Manufacturing Tolerances

For large infrastructure and foundation engineering projects, the correct specifications are more important than the welding method itself, as they directly affect load-bearing capacity, installation feasibility, and total project cost.

2. Spiral Welded Pipe Diameter Range

One of the most significant advantages of spiral welded pipes is their wide diameter range.

In practical applications, spiral welded pipes are typically used in medium to large diameter sizes, making them ideal for applications where ERW welded pipes or seamless pipes are inefficient or prohibitively expensive.

From an Engineering Perspective:

Smaller diameter spiral welded pipes are often used for water supply pipelines and auxiliary pipelines. Larger diameter spiral welded pipes are more suitable for pile foundations, offshore structures, and long-distance pipelines.

Because the steel strip is spirally formed, spiral welded pipes offer greater flexibility in diameter adjustment compared to straight-seam welded pipes.

3. Spiral Welded Pipe Wall Thickness

Wall thickness is another key parameter directly affecting structural strength and pressure resistance.

|

Outside Diameter (OD)

|

OD (mm)

|

Common Wall Thickness (mm)

|

Typical Applications

|

|

16″ – 24″

|

406 – 610

|

6 – 14

|

Water transmission, low - pressure pipelines

|

|

26″ – 36″

|

660 – 914

|

8 – 16

|

Water pipelines, industrial pipelines

|

|

38″ – 48″

|

965 – 1219

|

8 – 18

|

Oil & gas pipelines, transmission lines

|

|

50″ – 60″

|

1270 – 1524

|

10 – 22

|

Large - diameter pipelines, marine projects

|

|

62″ – 80″

|

1575 – 2032

|

12 – 25

|

Steel pipe piles, offshore & foundation works

|

|

82″ – 120″

|

2083 – 3048

|

14 – 30

|

Heavy piling, port & bridge foundation

|

Note:Actual spiral welded pipe dimensions may vary depending on applicable standards, steel grades, and project requirements.

Spiral welded pipes are available in various wall thicknesses to meet the following needs:

Axial load requirements in pile foundation engineering;

Internal pressure requirements in piping systems;

Bending and fatigue requirements in infrastructure construction.

It should be noted that while increasing wall thickness improves strength, it also increases material costs and welding volume. For most projects, selecting an appropriate wall thickness based on actual load calculations is more economical than over-designing for a thicker wall.

4. Spiral Welded Pipe Length Selection

The flexibility in length selection for spiral welded pipes is a major advantage in large-scale projects.

Common lengths include:

Random lengths for general building applications;

Fixed lengths for pipe alignment and improved welding efficiency;

Extended lengths for pile foundations and offshore structures.

Longer pipe sections reduce the number of on-site welds, thereby improving installation efficiency and overall project reliability.

5. Standards and Grades of Spiral Welded Pipes

Spiral welded pipes are manufactured according to international standards based on their intended use.

ASTM A252 is widely used in structural and foundation applications because it focuses on yield strength and load-bearing capacity.

For pipeline transportation, API 5L is a commonly used specification, covering different strength grades such as X42, X52, and X60. These grades allow engineers to balance pressure requirements, safety margins, and cost considerations. Choosing the correct standard ensures compliance with project specifications and regulations.

6. Manufacturing Tolerances and Dimensional Accuracy

Dimensional tolerances define the permissible deviations from diameter, wall thickness, and straightness.

Spiral welded pipes typically feature:

Controllable outer diameter tolerances;

Uniform wall thickness distribution;

Stable roundness over a large diameter range.

While ERW pipes may offer tighter tolerances at smaller sizes, spiral welded pipes offer excellent dimensional stability in large-diameter applications, which is where they are most commonly used.

7. Spiral Welded Pipe Specifications vs. ERW Pipes

From a specifications perspective, the main differences between spiral welded pipes and ERW pipes lie in dimensional flexibility and economy.

Spiral welded pipes are more suitable for: large diameters, thick-walled structures, and projects requiring custom sizes.

ERW pipes are generally suitable for: small to medium diameters and applications with extremely high dimensional tolerance requirements.

Understanding these differences helps engineers and purchasing personnel select the most suitable pipe type based on actual project needs.

8. How to Choose the Right Spiral Welded Pipe Specifications for Your Project

To select the correct specifications, consider the following factors:

Application type—piling, piping, or structural use; Applicable standards—ASTM, API, or project-specific requirements; Load or pressure conditions—structural loads and internal pressure; Installation method—onshore, offshore, or underground; Cost and delivery time—optimize design rather than over-design;

Appropriate specification selection improves performance and controls total project costs.

9. Frequently Asked Questions about Spiral Welded Pipe Specifications

What is the maximum diameter of spiral welded pipes?

Spiral welded pipes are typically produced in large diameters suitable for piling and piping projects. Specific sizes depend on production capacity.

Can spiral welded pipes be used in high-pressure applications?

Yes. As long as they are manufactured according to the relevant standards and wall thicknesses, spiral welded pipes can be used in a variety of pressure applications.

Are custom specifications available?

Custom diameter, wall thickness, and length specifications can be provided according to project requirements.

Read more : Spiral Welded Pipe: Manufacturing Process, Applications and Key Advantages