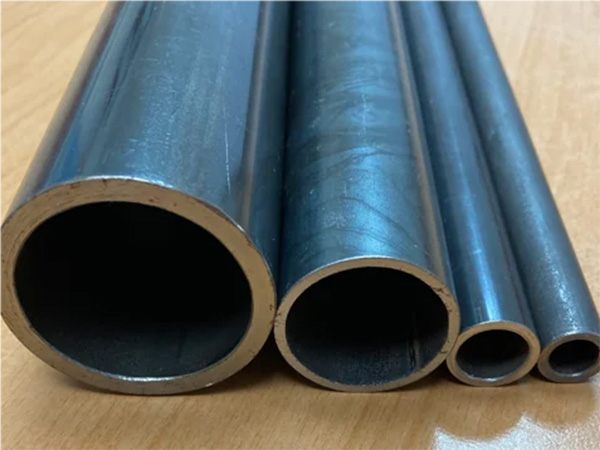

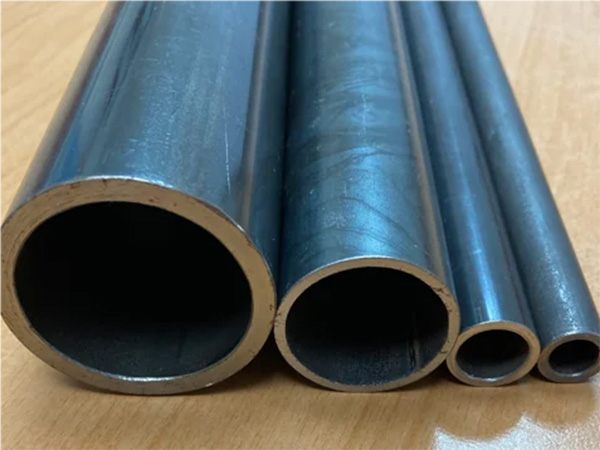

Carbon steel is a kind of metal material with iron and carbon as the main components, according to the different carbon content is divided into low carbon steel (below 0.25%), medium carbon steel (0.25%-0.60%) and high carbon steel (more than 0.60%). Carbon steel has high strength and durability, is easy to process and weld, and at the same time is low cost, so it has become one of the most commonly used materials in industrial and civil pipeline engineering.

Advantages of carbon steel in pipes

1. Strength and durability

The pipe made of carbon steel has good tensile strength and bearing capacity, which is suitable for high pressure and high temperature environment.

2. Cost effective

Carbon steel materials are easy to large-scale production, low price, and have significant advantages in economic terms.

3. Good processability

Carbon steel is easy to weld, bend and cut, and pipes of different sizes and shapes can be customized according to engineering needs.

The main application of carbon steel pipe

1. Industrial sector

Oil and natural gas: used to transport oil, natural gas and other fluids, widely used in oil pipelines and natural gas pipe networks.

Chemical engineering: Used for chemical media (such as acid, alkali, salt solution) transportation and storage equipment manufacturing.

2. Construction works

Water supply and drainage system: It is used for water supply and drainage pipes, especially in underground or in the case of high strength demand.

Heating, ventilation and Air conditioning (HVAC) : for refrigerant delivery and heating pipes.

3. Energy sector

Thermal power generation: used to transport steam and cooling water.

Nuclear and renewable energy: suitable for process pipelines in high temperature and high pressure environments.

4. Mechanical manufacturing

Frame structure: used as support and framing material for mechanical equipment.

Conveying drum: Conveying system for logistics equipment.

Limitations of carbon steel piping

1. Insufficient corrosion resistance

Untreated carbon steel is easy to oxidize and rust, and is not suitable for strong corrosive environment.

2. Large weight

Carbon steel is dense and heavier than lighter materials such as aluminum alloy, making it unsuitable for weight-sensitive works.

3. Low temperature performance is poor

At extremely low temperatures, the toughness of carbon steel will be reduced and brittle fracture may occur.

Improvement measure

1. Surface treatment

Improve corrosion resistance by galvanizing, spraying epoxy or adding coatings.

2. Alloying improvement

Add trace alloying elements (such as chromium, nickel, molybdenum) to improve corrosion resistance and wear resistance.

3. Optimize pipeline design

For high pressure, high temperature occasions, choose thick wall carbon steel pipe or composite material pipe.

Conclusion

Carbon steel with its high strength, easy processing, cost-effective advantages, has become an indispensable pipeline material in modern industry, construction and energy fields. Through surface treatment and alloy improvement, carbon steel is more widely used in complex working conditions, and will still be one of the important choices of future pipeline materials.

Read more : Piping materials- alloy steel or Piping materials-stainless steel