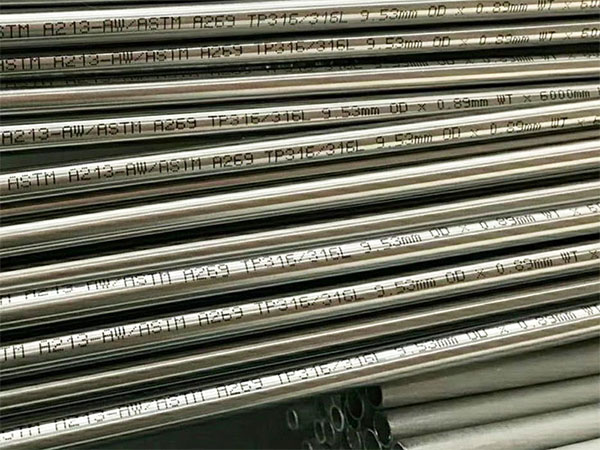

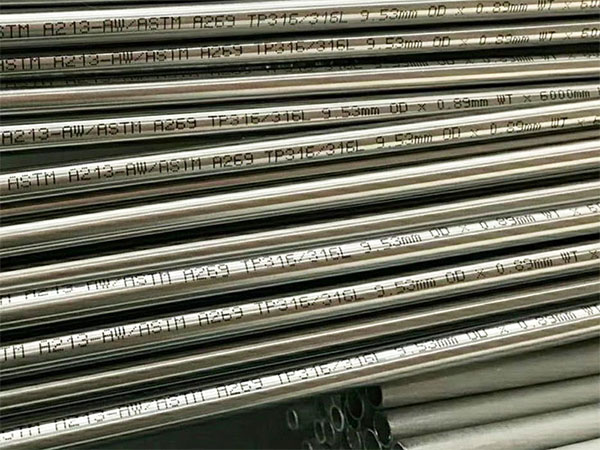

ASTM A269 stainless steel pipe is a stainless steel pipe produced in accordance with the American Society for Materials and Testing (ASTM) A269 standard, which is mainly used in low and medium pressure fluid delivery systems.

What is ASTM A269 standard?

ASTM A269 specification is used for general corrosion resistance and high or low temperature services. These tubes are highly durable and they can withstand high temperatures without losing strength. It is mainly used to withstand corrosive media transportation in the general environment, and is widely used in chemical, food, medicine, pharmaceutical and other industrial fields.

Common materials include austenitic stainless steel, such as

304,

304L,

316,

316L and so on. These stainless steels have become the main choice for the production of A269 stainless steel tubes because of their excellent corrosion resistance and good weldability.

Manufacturing method

ASTM A269 stainless steel tubing can be manufactured by two main processes:

Seamless pipe manufacturing

Perforation or drawing process to manufacture seamless pipes, this process does not have welded joints, to ensure the integrity and uniformity of the pipe, suitable for high pressure and corrosion resistance occasions.

Welded pipe manufacturing

Stainless steel sheets or strips are processed into tubes using cold forming and welding processes, followed by a series of welding, heat treatment and subsequent processing steps to ensure that the quality of the weld is consistent with the properties of the substrate.

Welded pipe is generally suitable for low to medium pressure conveying systems, and the manufacturing cost is relatively low.

Performance characteristics

Excellent corrosion resistance

Due to the high proportion of chromium and nickel, the surface of A269 stainless steel pipe forms a dense chromium oxide protective film, which shows good corrosion resistance in acid, alkali, salt spray and other environments.

Good mechanical properties

It has high tensile strength and extensibility, which can meet the requirements of general fluid transportation and structural connection, and has good impact resistance and fatigue resistance.

Weldability and machinability

Austenitic stainless steel (such as 304

and 316 series) has good weldability and formability, which is easy to cut, weld, bend and other subsequent processing.

Hygienic and aesthetic

The surface is smooth and easy to clean, suitable for food, medicine and other applications with high hygiene requirements, and also has a good decorative effect.

Application field

Due to its excellent corrosion resistance and mechanical properties, ASTM A269 stainless steel pipes are mainly used in:

Fluid delivery systems: Used to transport a wide range of liquids and gases in the chemical, pharmaceutical, food and beverage industries to ensure safe, reliable and hygienic fluid delivery.

Equipment manufacturing: In the manufacture of reactors, heat exchangers, storage tanks and other equipment, stainless steel pipe as a key component to provide high corrosion resistance and structural stability.

Construction and decoration: Because of its beauty and weather resistance, stainless steel pipes are also often used in modern architectural decoration and curtain wall structures.

Conclusion

ASTM A269 stainless steel pipe is a standardized stainless steel pipe product with excellent corrosion resistance, good mechanical properties and excellent weldability. Whether using seamless process or welding process, A269 pipe can meet a variety of low to medium pressure environment application requirements, widely used in chemical, food, medicine and construction fields.