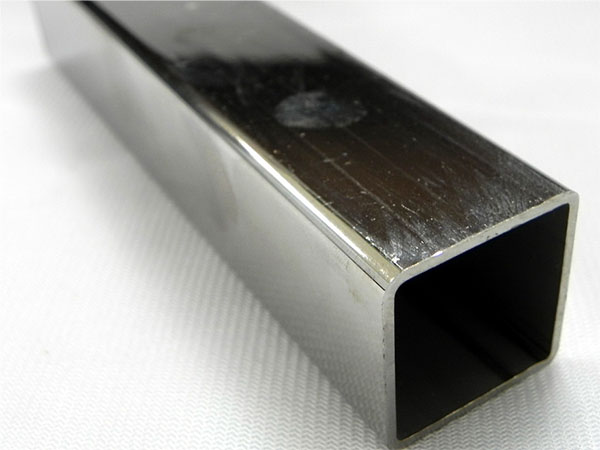

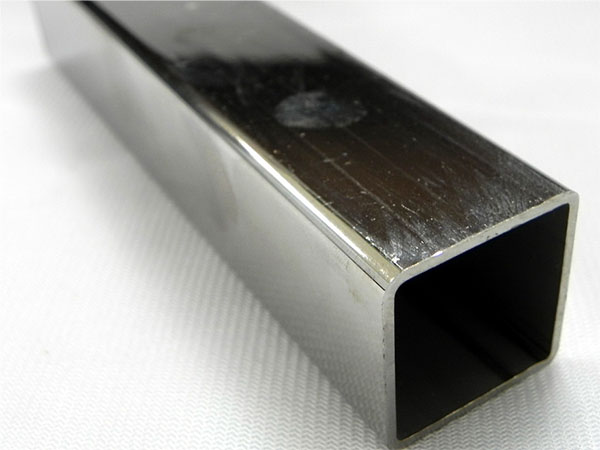

Square tube, a type of tube often used in building materials and structural decoration. It is usually square or rectangular in cross-section and is usually made of steel plates or strips that are machined, welded, cold-drawn or cold-rolled. In this paper, the definition, classification and application of square pipe will be introduced in detail.

Definition of square tube:

Square tube is a hollow thin-wall steel tube with a rectangular or square cross-section, which has also become a steel cooling bending profile. It is mainly a hot-rolled or cold-rolled steel plate or steel strip as the base material, and a square cross-section profile made by high-frequency welding after cold-bending molding. Because of its regular section shape, high strength and excellent bending resistance, square tube is widely used in building structure, machinery manufacturing, decoration and other fields.

Classification of square tube:

According to different classification standards, square tubes can be divided into the following types:

1. Classification by material:

(1) Carbon steel square tube: made of carbon structural steel, such as Q235, Q345, etc., cost-effective.

(2) Alloy square tube: the square tube contains alloying elements, which improves the strength and corrosion resistance, and is suitable for specific purposes.

(3) Stainless steel square tube: stainless steel material, such as 304, 316 stainless steel, has excellent corrosion resistance.

2. Classification by production process:

(1) Seamless square tube: The seamless steel pipe is processed into a square section by hot rolling or cold drawing, and the wall thickness is uniform, suitable for high-strength occasions. It can also be subdivided into hot-rolled seamless square steel and cold-rolled (cold-drawn) seamless square pipe.

(2) Welded square tube: made of steel plate or steel strip through high-frequency welding production, low production cost, suitable for ordinary structural purposes. According to the welding process can also be divided into arc welding and resistance welding two kinds of square pipe, according to the weld can also be divided into straight seam welding and spiral welded square pipe.

(3) Extruded seamless square tube: It is heated by the perforated billet and put into the mold, and is squeezed into the pipe through the annular gap between the die hole and the mandrel.

3. Classification according to production standards: according to the production standards of different countries can be divided into national standard, Japanese standard, British system, American standard, European standard, non-standard and other different classifications.

4. Classification by use:

(1) Structural square tube: widely used in building frames, Bridges, scaffolding and other bearing structures.

(2) Decorative square tube: used for furniture, railings, doors and Windows and other decorative occasions.

(3) Conveying square tube: used for conveying low-pressure fluids (such as water, gas, oil).

5. Classification by surface treatment:

(1) Black square tube: The surface is not treated, and there is a layer of black iron oxide.

(2) Galvanized square tube: surface galvanized, improve the corrosion resistance.

(3) Painted square tube: The surface is coated with anti-corrosion paint to increase the aesthetics and anti-corrosion ability.

6. By wall thickness:

(1) Thin-walled square tube: the wall thickness is thin, the weight is light, and it is suitable for light structure and decoration.

(2) Thick wall square tube: the wall thickness is large, the bearing capacity is strong, suitable for high strength and high pressure environment.

Uses of square tube:

1. Building structure: mainly used for steel structure frames, Bridges, scaffolding and other bearing structures, can also be used for fences, door and window frames and decorative components.

2. Mechanical manufacturing: used for mechanical equipment support, transmission shaft and frame in automobile manufacturing.

3. Fluid transport: Can be used to transport low pressure fluids, commonly found in water supply, gas and heating systems.

4. Furniture and decoration: It can be used for the manufacture of furniture frames, such as table and chair frames, and can also be used for indoor and outdoor structural decoration to enhance its beauty and practicality.

The identification method of square tube is mainly expressed by side width * side width * pipe wall thickness. For example, 50×50×4 mm means that the side width is 50mm and the closing thickness is 4mm.