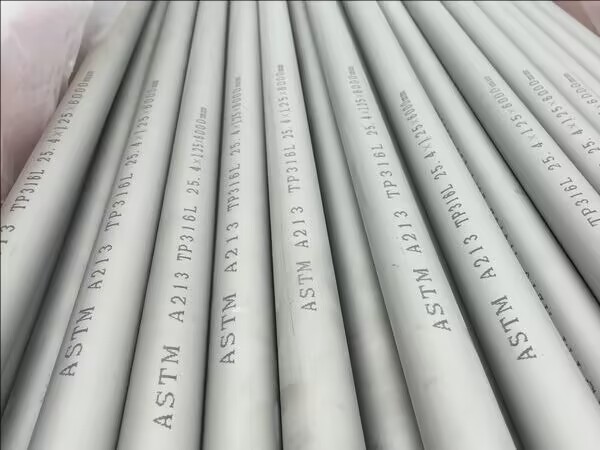

Precision seamless steel pipe: characteristics and applications

Precision

seamless steel pipe is a kind of high-precision steel pipe produced by cold rolling or cold drawing process, and its full name is cold-rolled or cold-drawn precision seamless steel pipe. This steel pipe has many unique advantages, such as no oxide layer in the inner and outer walls, can withstand high pressure and no leakage, high dimensional accuracy, high surface finish, and no deformation, no cracking and other excellent mechanical properties during cold bending, flaring or flattening.

Precision seamless steel pipes are mainly used to manufacture pneumatic and hydraulic components, such as hydraulic cylinders or oil cylinders, which require high reliability and accuracy. This steel pipe is ideal for critical applications due to its excellent performance.

Advantages of cold-drawn precision seamless steel pipe

Cold-drawn precision seamless steel pipes are designed for mechanical structures and hydraulic equipment, where dimensional accuracy and surface quality are highly required. This type of steel pipe has the following significant advantages:

Improve manufacturing efficiency

In the manufacture of mechanical structures and hydraulic equipment, the use of precision seamless steel pipes can significantly reduce machining needs, directly shorten processing time, improve material utilization, and thus significantly improve production efficiency.

High dimensional accuracy

The inner diameter, outer diameter and wall thickness of precision seamless steel pipes are strictly tolerance controlled to ensure dimensional consistency and accuracy, especially for complex assembly and high-precision application scenarios.

Excellent surface finish

The smooth and flat surface of the precision-machined steel pipe not only improves aesthetics, but also reduces friction losses in hydraulic and pneumatic systems.

Compact material, reliable performance

The cold drawing process makes the metal structure more dense, thus improving the strength and reliability of the steel pipe, which is suitable for high pressure and high strength environments.

The main characteristics of ordinary seamless steel pipe

Although the ordinary seamless steel pipe is not as fine as the precision steel pipe, it still has the following characteristics:

Weldless construction

Seamless steel pipes have no welded gaps, so they have stronger pressure resistance and can provide reliability in a variety of working conditions.

Basic production process

Ordinary seamless steel pipes can be manufactured by rough casting or cold drawing process, and the production flexibility is high.

Wide dimensional tolerances

Compared with precision steel pipes, ordinary seamless steel pipes have looser tolerance and surface finish control.

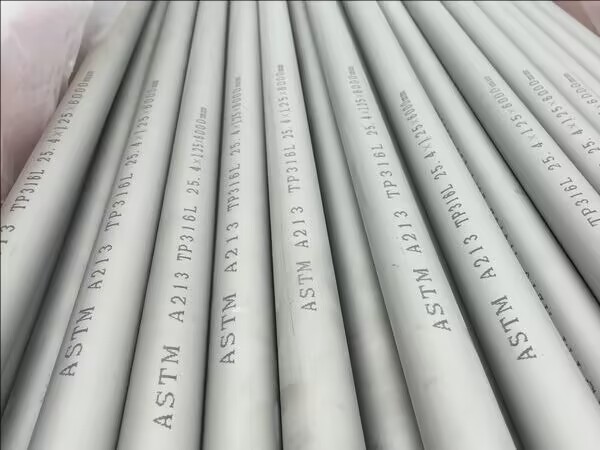

Characteristics of cold-drawn (rolled) precision steel pipes

Cold-drawn precision steel pipes have the following significant characteristics on the basis of ordinary seamless steel pipes:

The outside diameter is smaller

The cold drawing process can produce steel pipes with smaller outer diameters to meet the needs of special applications.

High precision, suitable for small batch production

This kind of steel pipe has high precision in production, suitable for customized small batch production, and stable and reliable performance.

Excellent surface quality

The cold drawing process gives the surface of the steel pipe a very high finish without additional polishing or machining.

Complex section shape

The complex section design can be realized in the production process to meet the diversified industrial needs.

Superior mechanical properties

The metal densification after cold drawing makes the steel pipe perform well in terms of strength, toughness and durability, and can be used for a long time in harsh environments.

Summary

Precision seamless steel pipe is a leap in industrial material innovation. Its combination of high strength, high precision and high finish has redefined the standard for modern manufacturing and engineering. This steel pipe can not only significantly improve production efficiency and reduce material waste, but also provide more reliable and higher quality solutions for industrial production.

In the aerospace, automotive, energy and other industries, there is a growing demand for high-performance materials. With superior performance, precision seamless steel pipes will continue to be at the forefront of technological development, driving industrial innovation and ensuring the reliability of critical systems.