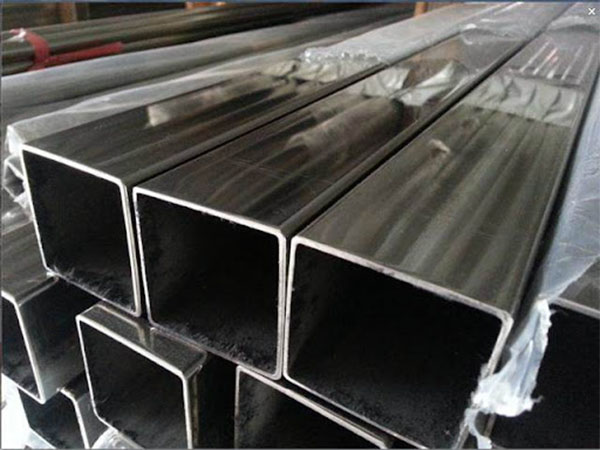

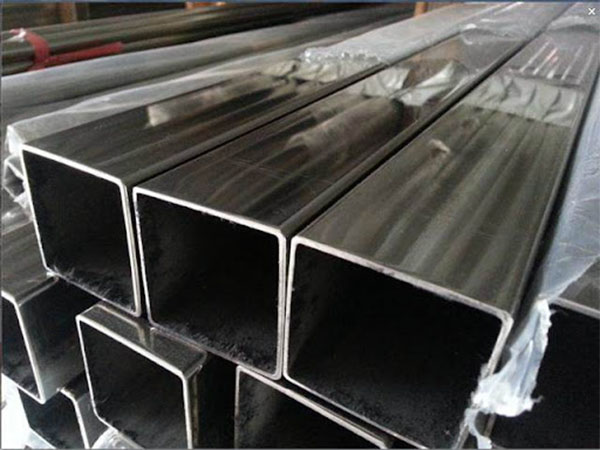

As a commonly used building material,

stainless steel square pipe due to the high material value and strict surface quality, so special attention should be paid to protecting the surface during packaging and transportation to prevent scratches, pollution and corrosion, while ensuring that no deformation occurs in transportation engineering. Common packaging and transportation methods and precautions are as follows:

1. Prepare before packaging

Surface cleaning and protection

Clean the stainless steel square pipe thoroughly before packaging to remove oil, dust and other impurities. If necessary, a layer of protective paint or film can be sprayed on the surface to prevent scratches or oxidation during transportation.

Inspection and sorting

Inspect the size, appearance and quality of the pipes to ensure that all products meet the standards and avoid subsequent installation due to product damage.

2. Packing method

Inner packing

In the packaging process of stainless steel square tubes, it is first necessary to carry out internal packaging. The inner packaging is to protect the surface of the stainless steel square pipe from scratches and collisions. A waterproof, tear resistant plastic film or PE film is often used to wrap the square pipe, forming the first protective layer to prevent moisture and contaminants from contacting the metal surface.

For stainless steel products with higher surface requirements, cushioning materials, such as foam board or bubble film, can also be added to the plastic film to reduce friction and impact during transportation.

Outer packing

The outer packaging is to protect the stainless steel square tube of the inner packaging to prevent it from being affected by external forces during transportation. The commonly used outer packing materials are wooden boxes, plastic packaging and woven bags. Wooden box is a common outer packing material, with large size or long stainless steel square pipe, usually using custom wooden boxes for packing, the wooden box can be laid inside the shock-proof pad and foam board, to ensure that the pipe in the transport process is not squeezed, collision.

For small and medium-sized stainless steel square pipes, steel tape or nylon tape can be firmly bound, and then the moisture-proof plastic bag or carton packaging. Ensure that the strapping is secure to prevent sliding and bumping into each other during handling and transportation.

3. Fixation method

In order to ensure that the stainless steel square pipe does not move and collide during transportation, it is necessary to adopt a fixed way of packaging. The commonly used fixing methods are strapping, filling and fixing pallets. Strapping is to bind a number of stainless steel square tubes together with rope or wire to ensure that they will not collide with each other. Filling is the use of filler, such as foam or cardboard, around the stainless steel square pipe to fill the gap between the pipe and the box to prevent the pipe from moving during transportation. The fixed tray is to place the stainless steel square tube on the tray and firmly fix it with plastic film or rope to ensure the overall stability.

4. Mode of transportation and precautions

Container transport

For long-distance or international transportation, standard containers are recommended. The container is laid with shock-proof cushion, and the stainless steel square pipe is fixed horizontally or vertically on the cargo tray to avoid surface damage caused by vibration and collision during transportation.

Truck or rail transport

Use a dedicated steel carrier or flatbed truck for loading. For large square pipes, binding straps and fixing devices must be used to ensure that the square pipes will not be displaced or collided due to bumps or sharp turns during transportation.

Moisture and rust prevention measures

Although stainless steel has good corrosion resistance, it is still necessary to pay attention to prevent the intrusion of moisture and chemical substances during transportation. Use waterproof packaging materials and desiccant to help protect product quality.

Identification and recording

Clear labels should be affixed on the outside of the packing box or wooden box, including product specifications, quantities, destinations and precautions, to facilitate logistics management and tracking of goods.

Conclusion

The packaging and transportation of stainless steel square pipes need to be comprehensively considered from many aspects such as surface protection, internal and external packaging, fixing and shock-proof, moisture-proof and rust-proof, and transportation mode selection. Through the use of a variety of different packaging methods and fixing and protective measures to ensure the quality and performance of the steel pipe intact, improve customer satisfaction with the overall quality of the product.