ERW steel pipe VS Seamless steel pipe: Whether ERW steel pipe can replace seamless steel pipe

ERW steel pipe and

seamless steel pipe are two common types of steel pipe, they have significant differences in production process, performance, and application scenarios. What is the difference between ERW steel pipe and seamless steel pipe, and can ERW steel pipe replace seamless steel pipe? This article will focus on these two points for a detailed introduction.

The difference between ERW steel pipe and seamless pipe

1. The difference in manufacturing process

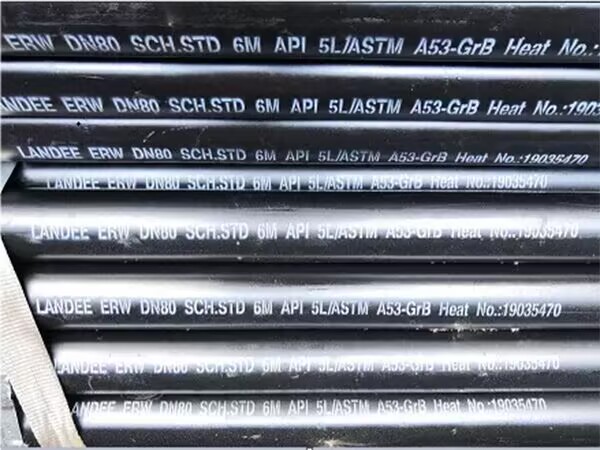

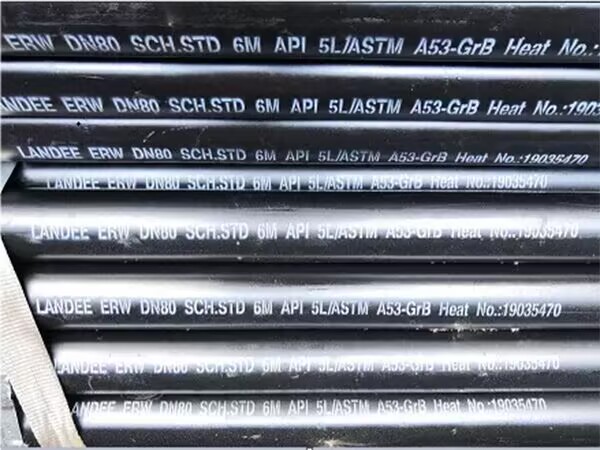

ERW steel pipe: The steel strip is rolled through a series of rolls into the tube, which is produced by a high-frequency resistance welding process, and the tube wall is welded without perforation and drawing.

Seamless steel pipe: made of solid round steel billet by heating perforation, hot rolling, cold drawing or cold rolling process, no weld.

2. Differences in appearance

ERW steel pipe: The surface of the pipe body is smooth, and there are obvious welds inside and outside.

Seamless steel pipe: there is no weld on the surface, and the whole steel pipe is uniform.

3. Performance and application differences

(1) Strength and pressure resistance: the seamless steel pipe has stronger pressure resistance because it has no weld as a whole, and is suitable for high pressure, high temperature or harsh application environments, such as boiler pipes, hydraulic pipes, etc. ERW steel pipes have welds, welds are easy to become weak points, poor pressure resistance, suitable for low-pressure environments, such as water and gas pipelines.

(2) Dimensional accuracy: seamless steel pipe due to its processing technology, the size of the tolerance is large. ERW steel pipe diameter and wall thickness control is more precise, suitable for applications requiring high precision.

(3) Cost: The manufacturing process of seamless steel pipe is complex and the cost is relatively high. ERW steel pipe because of its relatively simple manufacturing process, the utilization rate of raw materials is high, so the cost is relatively low.

Can ERW steel pipe replace seamless steel pipe?

With the development of science and technology and The Times, the welding technology of ERW steel pipe is getting better and better, and the performance of ERW steel pipe is getting closer and closer to seamless steel pipe, which can be used to replace seamless steel pipe in many occasions.

Although ERW steel pipe has many advantages, it can not completely replace seamless steel pipe. In some applications with strict requirements for strength and durability, seamless steel pipes are still preferred.

Alternative situations: In low and medium pressure transportation (such as water, oil, gas and other pipelines) and structural parts with low performance requirements, ERW steel pipes can replace seamless steel pipes.

In applications with high pressure, high temperature, strong corrosion or high bearing capacity requirements (such as boiler pipes, chemical equipment, high-pressure vessels, etc.), ERW steel pipes cannot completely replace seamless steel pipes.

Conclusionerw

ERW steel pipes and seamless steel pipes have their advantages and disadvantages, and whether they can be replaced depends on the specific use scenario. If the performance requirements are high, it is recommended to use seamless steel pipe; If you pay attention to economy and moderate performance requirements, you can choose ERW steel pipe.