Chemical composition:

|

Grade |

C(%) |

Mn(%) |

P(%) |

S(%) |

Si(%) |

Cr(%) |

Mo(%) |

|

P1 |

0.10-0.20 |

0.30-0.80 |

≤0.025 |

≤0.025 |

0.10-0.50 |

|

0.44-0.65 |

|

P2 |

0.10-0.20 |

0.30-0.61 |

≤0.025 |

≤0.025 |

0.10-0.30 |

0.50-0.81 |

0.44-0.65 |

|

P5 |

≤ 0.15 |

0.30-0.60 |

≤0.025 |

≤0.025 |

≤0.50 |

4.00-6.00 |

0.44-0.65 |

|

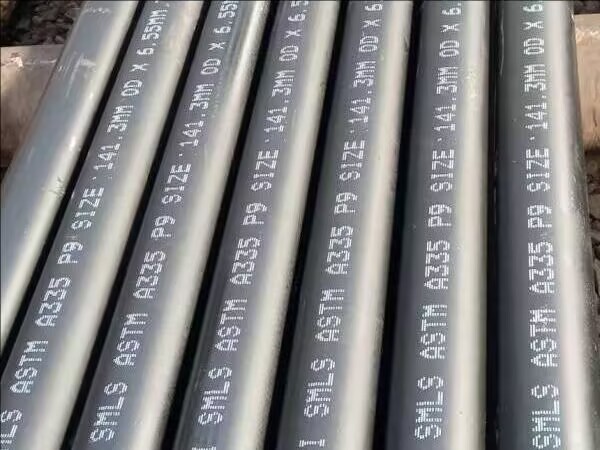

P9 |

≤ 0.15 |

0.30-0.60 |

≤0.025 |

≤0.025 |

0.50-1.00 |

8.00-10.00 |

0.44-0.65 |

|

P11 |

0.05-0.15 |

0.30-0.61 |

≤0.025 |

≤0.025 |

0.50-1.00 |

1.00 - 1.50 |

0.44-0.65 |

|

P22 |

0.05-0.15 |

0.30-0.60 |

≤0.025 |

≤0.025 |

0.50-1.00 |

1.90 - 2.60 |

0.87-1.13 |

|

P91 |

0.08-0.12 |

0.30-0.60 |

≤0.020 |

≤0.010 |

0.20-0.50 |

8.00 - 9.50 |

0.85-1.05 |

Mechanical properties:

|

Grade |

Yield Strength(MPa) |

Tensile Strength(MPa) |

|

P1 |

≥ 205 |

≥ 380 |

|

P2 |

≥ 205 |

≥ 380 |

|

P5 |

≥ 205 |

≥ 415 |

|

P9 |

≥ 205 |

≥ 415 |

|

P11 |

≥ 205 |

≥ 415 |

|

P22 |

≥ 205 |

≥ 415 |

|

P91 |

≥ 415 |

≥ 585 |

Application of ASTM A335 pipe

Because of the addition of chromium and molybdenum elements in ASTM A335 pipe, the tensile strength, high temperature resistance and corrosion resistance of the steel pipe are significantly improved. Due to its high temperature and high pressure resistance, ASTM A335 tubes are commonly used in power plants, refineries, petrochemical plants and oilfield services. The fields of application of different grades of steel are also different. The most common uses of P11, P22 and P91 tubes are in the power industry and petrochemical plants, and P5 and P9 tubes are usually used in refineries.

ASTM A335 tube test method

ASTM A335 has strict test requirements for the quality and performance of steel pipes, and the common test methods are as follows:

Hydrostatic test: The curved inner diameter should be 1 inch [25 mm]. Each pipe shall be hydraulically tested, and non-destructive electrical testing may be used optionally during manufacturing.

Ultrasonic test: Through ultrasonic detection of whether there is damage in the pipe body, and to detect whether the element content in the steel pipe meets the specifications.

Hardness test: The hardness of P91 shall not exceed 250 HB/265 HV [25HRC].

Dimensional check

Size range: Nominal pipe diameters (NPS) are available from small to large diameters, with various wall thickness standards such as SCH 40, SCH 80, SCH 160.

Heat treatment requirement

According to different grades and applications of steel pipes need to be subjected to corresponding heat treatment (such as annealing, normalizing, or quenching and tempering).

|

Grade |

Heat treatment method |

Heat treatment temperature range |

|

P1 |

Full annealing or normalizing plus tempering |

650 - 700 |

|

P2 |

Normalizing plus tempering |

650 - 700 |

|

P5 |

Normalizing plus tempering or quenching plus tempering |

675 - 750 |

|

P9 |

Normalizing plus tempering or quenching plus tempering |

700 - 780 |

|

P11 |

Normalizing plus tempering |

675 - 775 |

|

P22 |

Normalizing plus tempering |

675 - 775 |

|

P91 |

Quenching plus tempering |

Quenching: 1040 - 1080 Tempering: 730 - 780 |