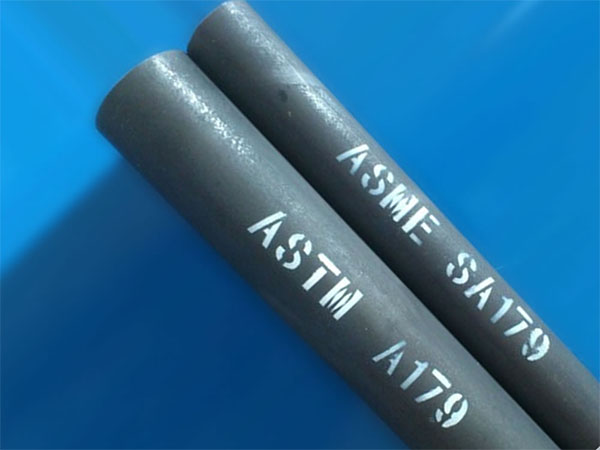

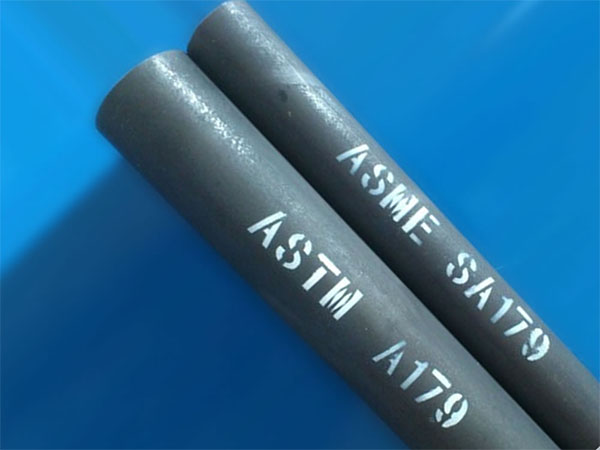

ASTM A179 is a low carbon steel standard for cold-drawn seamless steel pipes used in the manufacture of heat exchangers, condensers and other heat exchange equipment requiring high precision and high pressure resistance. These tubes are designed to withstand high pressures and temperature differences while ensuring efficient heat transfer. The following are the characteristics of ASTM A179 cold-drawn seamless steel pipe:

1. Process characteristics

ASTM A179 steel pipe is cold-drawn to provide higher dimensional accuracy and surface finish to meet the requirements of thin-wall and high-precision pipes for heat transfer equipment. And it adopts seamless structure, no weld design to ensure the integrity of the pipeline and high pressure resistance, reducing the risk of pipeline leakage.

2. Material characteristics

ASTM A179 steel pipe carbon content is usually between 0.06% and 0.18%, with a low carbon content, low carbon content gives it good toughness and plasticity, easy to process and weld. At the same time, due to its pure material and uniform chemical composition, ASTM A179 steel pipe has better thermal conductivity and higher efficiency in the heat transfer process.

3. Performance characteristics

High strength: The characteristics of low carbon steel enable ASTM A179 tubes to withstand high working pressures and have good impact resistance.

High temperature resistance: ASTM A179 also has high temperature resistance and is suitable for high temperature and high pressure environments, especially in heat exchange equipment.

Machinability: The steel pipe is easy to cut, bend, flaring, shrinking and other secondary processing, to meet the needs of complex equipment design.

4. Size and wall thickness characteristics

Thin wall design :ASTM A179 steel pipe is mainly thin wall, suitable for the manufacture of efficient heat exchange tubes in heat exchange equipment.

High dimensional accuracy: The cold drawing process ensures high accuracy of inner and outer diameters and wall thicknesses for demanding industrial applications.

Note:

When ASTM A179 steel pipe is used for heat exchange or condenser pipe, in order to ensure its performance and service life, the following matters must be noted:

1. Transportation and storage

In the process of transportation, the surface of the steel pipe should be avoided from receiving impact, scratches or other mechanical damage. Before storage, clean the pipe surface and apply anti-rust oil according to environmental conditions to prevent oxidation and rust caused by moisture, rain or corrosive environment.

2. Processing matters

When welding, the heat input should be strictly controlled to avoid changes in carbon content or deterioration of material properties due to excessive temperature.

When cutting, professional equipment should be used to avoid burrs or cracks on the internal and external surfaces due to improper cutting.

3. Installation matters

ASTM A179 steel pipe has a high precision, should be installed to ensure that the size of the joint or fittings match, to avoid the size error caused by the reduction of sealing or structural loosening.

Summary

ASTM A179 Cold-drawn seamless steel pipe has become an indispensable key material in industrial heat exchange equipment due to its excellent physical properties and processing properties. Its thin-wall design, high precision and seamless structure ensure reliability under high pressure and high temperature environments, providing an important guarantee for heat transfer efficiency and equipment durability.