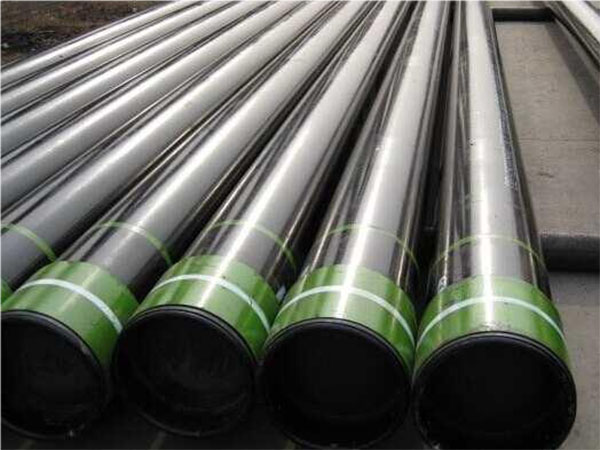

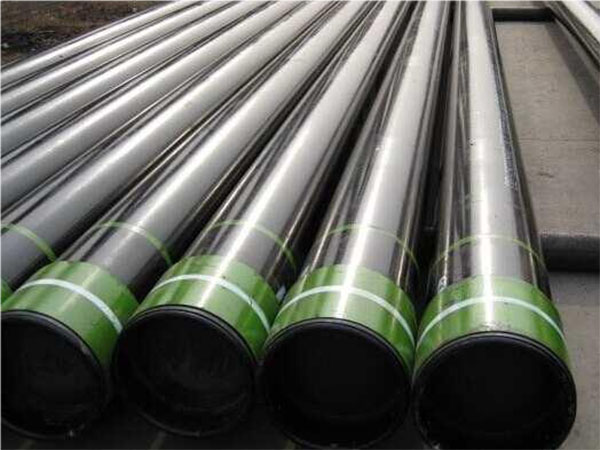

With the increasing exploitation and utilization of oil and gas, the construction of oil and gas pipelines is becoming more and more important. Because of its high strength, corrosion resistance and good pressure resistance, seamless steel tube has become the main material choice for transmission pipelines in the oil and gas industry, and it is more and more widely used in oil and gas pipelines. The following will introduce the application and advantages of seamless steel tube in oil and gas pipelines in detail.

The characteristics of seamless steel tube

1. High strength and pressure resistance

Seamless steel tube is manufactured by integral hot rolling or cold drawing process, no weld, uniform strength distribution, and can withstand extremely high internal and external pressure. Excellent performance in deep Wells, high-pressure gas fields and long distance transportation.

2. Good corrosion resistance

Seamless steel tube surface is smooth, not easy to accumulate dirt, with good corrosion resistance. At the same time, the surface of the steel pipe can also be coated with anti-corrosion materials to resist chemical corrosion in the transport medium.

3. Wide range of applications

Seamless steel tubes can be used in various environments such as high temperature, high pressure, low temperature and low pressure, and the application range is very wide.

4. High reliability

Because there is no weld, there is no welding defect, reducing the risk of leakage and fracture, especially suitable for high pressure and high temperature conditions.

The application of seamless steel tube in oil and gas pipelines has the following advantages:

1. High safety: seamless steel tube has no joint, and it is not easy to have oil leakage, explosion and other safety accidents during use.

2. Good corrosion resistance: oil and gas pipelines are often affected by corrosion, and seamless steel tubes have good corrosion resistance, which can effectively extend the service life of pipelines.

3. Strong pressure resistance: oil and gas pipelines are often affected by high pressure, and the strength and pressure resistance of seamless steel tubes are relatively high, and they can withstand greater pressure.

4. Wide range of applications: seamless steel tube can be used in a variety of environments, a wide range of applications, can meet the needs of different occasions.

The concrete application of seamless steel tube in oil and gas pipeline

1. Stage of oil and gas exploitation

Casing: Used to support oil well walls, prevent wall collapse, and isolate oil, gas and water between different formations.

Tubing: Used to transport extracted crude oil and natural gas from the bottom of an oil well to the surface.

Drill pipe: used to connect the drill bit and transfer drilling power, wear resistance and high pressure.

2. Oil and gas transmission pipeline

Long-distance transportation: Seamless steel tube is the core component of long-distance oil and gas pipelines, especially in high-pressure pipelines, for transporting crude oil, natural gas and refined oil products.

Submarine pipeline: In the offshore oil and gas exploitation, used for submarine oil and gas transmission, the steel pipe is required to have high pressure resistance, corrosion resistance and fatigue resistance.

3. Processing and storage equipment

Tank piping: Used to connect tanks, valves and other equipment to adapt to the flow of media in high temperature and high pressure environments.

Oil refining and chemical pipeline: used to transport high temperature, highly corrosive chemical raw materials or products.

4. Pipeline under special conditions

Deep water drilling: Used to connect deep water drilling platforms to the formation and to withstand high pressure environments in deep water.

High temperature and high pressure gas fields: transporting high temperature, high hydrogen sulfide or carbon dioxide content of natural gas, need to have corrosion resistance and high pressure resistance.

Seamless steel tube key standards

The manufacture and application of seamless steel tubes must comply with relevant international standards to ensure their performance and safety:

API 5L

Steel pipe standard for conveying pipes, covering PSL1 and PSL2 quality grades.

API 5CT

Dedicated to the manufacturing requirements of oilfield tubing, including casing and tubing.

ASTM standard

ASTM A106/A53: Seamless carbon steel tubing for high temperature piping.

ASTM A333: Seamless tubing for use in low temperature environments.

ISO 3183

International standard for steel pipes for oil and gas transmission.

Conclusion

With its excellent performance, seamless steel tubes play a vital role in all stages of oil and gas pipelines. From oil well development to long-distance transportation, from surface equipment to deep-sea engineering, seamless steel tube has become an indispensable material for the oil and gas industry with its advantages of high strength, corrosion resistance and high reliability. In the future, with the technological progress of the energy industry, seamless steel tubes will continue to provide support in the application of higher standards and promote the development of the industry.