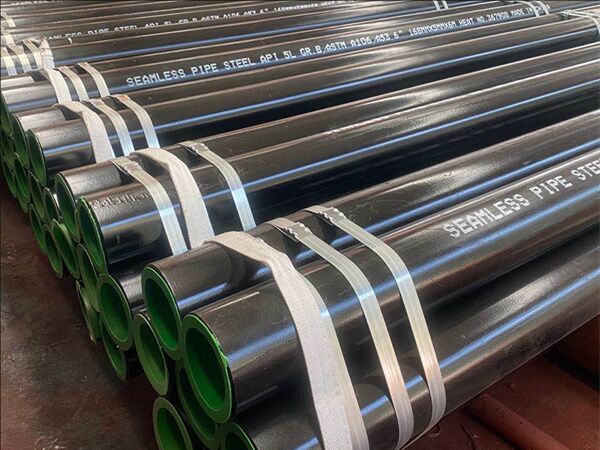

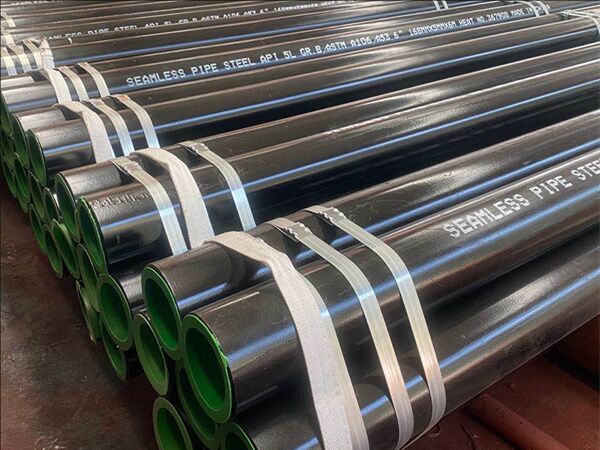

API 5L is an international standard for oil and gas transmission pipes, developed by the American Petroleum Institute (API) and widely used in the oil and gas industry. API 5L seamless steel tube as an important part of the standard, with high strength, good toughness and corrosion resistance, is the ideal choice for the transportation of oil, natural gas and other liquid media. The following will be a comprehensive introduction to API 5L seamless steel tube from the aspects of standard overview, main specifications, production process and application fields.

API 5L standard Overview

The API 5L standard covers the manufacturing requirements for conveying steel pipes, including seamless and welded steel tubes, in two quality classes:

PSL1 (Pipeline Steel Grade 1) : Used for conventional conveying requirements, suitable for lower pressures and general operating conditions.

PSL2 (Pipeline Steel Grade 2) : Higher requirements, including more stringent chemical composition, mechanical properties and non-destructive testing standards, suitable for high pressure, high temperature and corrosive environments.

API 5L seamless steel tubes are commonly used in pipelines with high performance requirements, especially in complex geological conditions and extreme environments.

API 5L seamless steel tube main specifications

Material grade

The API 5L standard includes a variety of material grades, such as:

Class B: For general use, suitable for medium and low pressure pipeline.

X42 to X80: Strength grades from X42 (minimum yield strength 42,000 psi) to X80 are suitable for high pressure or long distance pipelines.

Size range

Outer diameter: from 10.3mm to 1200mm (customized according to customer requirements).

Wall thickness: According to the standard requirements, it can meet the needs of thin wall and thick wall pipe.

Manufacturing tolerance

The API 5L standard has strict tolerance requirements for the outer diameter, wall thickness, length and port machining accuracy of the pipe to ensure the tightness and service life of the pipe connection.

Production technology

API 5L seamless steel tubes are manufactured by hot rolling or cold drawing processes, which include the following steps:

Raw material selection

Choose high-quality carbon steel or low alloy steel, chemical composition must meet API 5L standard requirements.

Punch forming

Using solid round steel billet, the seamless steel billet is produced by a perforating machine to ensure that there are no welding defects inside the steel pipe.

Hot rolled or cold drawn

Hot rolling or cold drawing of the tube billet according to customer requirements to ensure the dimensional accuracy and surface finish of the steel pipe.

Heat treatment

The steel pipe is normalized, annealed or quenched to improve its mechanical properties and corrosion resistance.

Quality inspection

Carry out chemical analysis, mechanical properties testing, ultrasonic testing and hydraulic testing to ensure that the product meets the standard requirements.

API 5L seamless steel tube performance characteristics

High strength

API 5L seamless steel tube has high tensile strength and yield strength, can withstand large internal and external pressure, suitable for long distance and high pressure conveying needs.

Corrosion resistance

Different anti-corrosion coatings can be selected according to the working environment, such as three-layer polyethylene (3PE), epoxy coating, etc., to resist the influence of seawater, acidic media and other corrosive environments.

Excellent toughness

The pipe has good toughness under both low and high temperature conditions and is suitable for use under extreme climate conditions.

Seamless construction

The weld-free design avoids welding defects and improves the safety and durability of the pipe.

Application field

Oil and gas transmission

API 5L seamless steel tube is the main pipeline for oil, natural gas and other chemical liquids, and can be used for land and sea transportation.

Urban pipe network construction

It is used for urban water supply, gas supply and heat transmission network to ensure the stability and long life of the pipeline.

High pressure pipeline

When transporting high pressure media such as high pressure natural gas, API 5L seamless steel tube is widely used because of its superior strength and sealing performance.

Extreme environment

Such as desert, cold areas or deep sea pipeline, API 5L seamless steel tube shows excellent corrosion resistance and pressure resistance.

Conclusion

API 5L seamless steel tube has become one of the core materials in the oil and gas industry due to its high performance, reliability and applicability. From standard specifications to performance characteristics to practical applications, API 5L seamless steel tubes always provide an efficient and safe solution for energy transportation worldwide. In the context of continued growth in energy demand in the future, API 5L seamless steel tubes will continue to play an indispensable role.