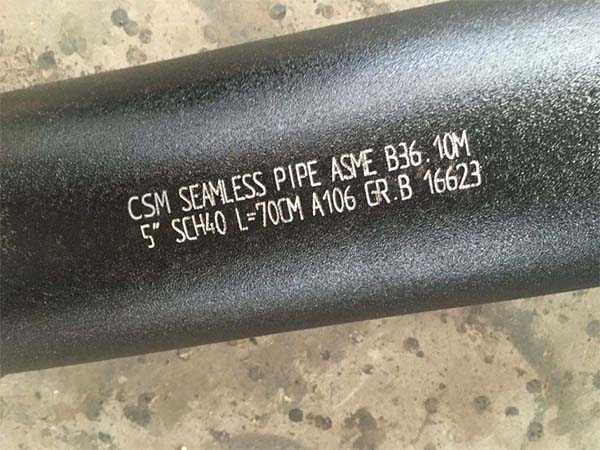

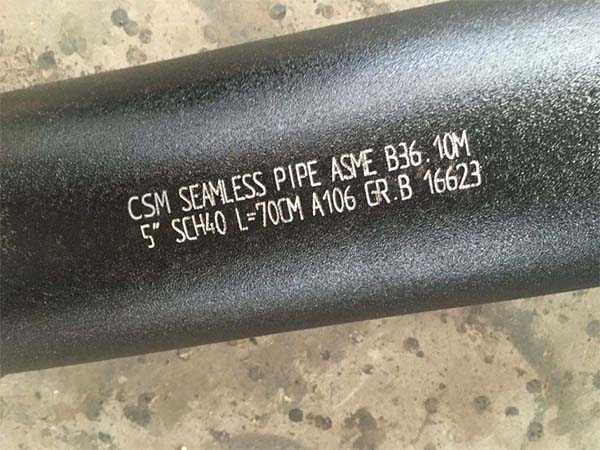

ASTM A106Es uno de los estándares más utilizados para tubos de acero al carbono sin costura de alta temperatura en todo el mundo, y se aplica ampliamente en calderas, centrales eléctricas, petroquímicos e industrias de refinación de petróleo.

En los proyectos internacionales de adquisición e ingeniería, los ingenieros y compradores a menudo se encuentran con esta pregunta: ¿A qué corresponde ASTM A106 en otras normas nacionales?

Este artículo proporcionará una tabla de comparación estándar equivalente completa, que cubre estándares como ASME, API, EN, DIN, BS y JIS, y analizará las diferencias en su composición química y propiedades mecánicas para ayudarlo a realizar la sustitución y selección correctas.

Introducción a ASTM A106

ASTM A106 es principalmente aplicable a tubos de acero al carbono sin costura en condiciones de trabajo a alta temperatura y se divide en tres grados: Grado A, Grado B y Grado C. Entre ellos, el Grado B es el más común en el mercado.

Aplicaciones comunes

Tubería de transporte de alta temperatura

Caldera e intercambiador de calor

Tubería del sistema de generación de energía

Tabla de comparación estándar equivalente

|

Standard

|

Grade

|

Chemical Composition (max %, unless noted)

|

Mechanical Properties

|

|

ASTM A106

|

Gr. B

|

C ≤ 0.30, Mn 0.29–1.06, P ≤ 0.035, S ≤ 0.035, Si ≥ 0.10

|

Tensile ≥ 415 MPa, Yield ≥ 240 MPa, Elong ≥ 30%

|

|

ASME SA106

|

Gr. B

|

Same as ASTM A106

|

Same as ASTM A106

|

|

API 5L

|

Grade B

|

C ≤ 0.28, Mn ≤ 1.20, P ≤ 0.030, S ≤ 0.030

|

Tensile ≥ 415 MPa, Yield ≥ 245 MPa

|

|

EN 10216-2

|

P265GH

|

C ≤ 0.20, Mn 0.80–1.40, P ≤ 0.025, S ≤ 0.015

|

Tensile 410–530 MPa, Yield ≥ 265 MPa

|

|

DIN 17175

|

St45.8

|

C ≤ 0.21, Mn 0.40–1.20, P ≤ 0.025, S ≤ 0.025

|

Tensile 410–530 MPa, Yield ≥ 255 MPa

|

|

BS 3059 Pt.2

|

360

|

C ≤ 0.23, Mn 0.40–1.06, P ≤ 0.040, S ≤ 0.040

|

Tensile 360–500 MPa, Yield ≥ 235 MPa

|

|

JIS G3454

|

STPG410

|

C ≤ 0.25, Mn 0.30–0.90, P ≤ 0.035, S ≤ 0.035

|

Tensile ≥ 410 MPa, Yield ≥ 245 MPa

|

Precautions

Although these standard performances are similar, they cannot be completely equated and interchanged, especially when used in pressure vessels or high-temperature working conditions, the chemical composition, mechanical properties and design specification requirements need to be rechecked.

If it is a boiler or heat exchanger project, it is recommended to directly use ASTM A106 GR.B or high-temperature standard steel pipes of equal strength.

Key analysis

1. Chemical composition differences

EN 10216-2 P265GH has a lower carbon content, stricter control over phosphorus and sulfur content, and better welding performance.

Although API 5L Grade B has similar strength, it is mainly used in conveying pipelines rather than high-temperature boilers.

2. Differences in mechanical properties

The yield strength of the European standard (EN/DIN) is generally higher than that of ASTM A106 Gr.B (240 MPa).

The tensile strength requirement of BS 3059 Pt.2 360 is lower and it is not suitable for high-pressure and high-temperature substitution.

3. Application Precautions

ASTM A106 or EN 10216-2 P265GH is recommended for high-temperature working conditions.

API 5L Grade B is optional for oil and gas pipelines.

The boiler tubes can be selected as DIN 17175 St45.8 or BS 3059.

How does ASTM A106 GR.B compare with ASTM A53 GR.B?

The strength levels of ASTM A106 Gr.B and ASTM A53 Gr.B are similar. However, A106 B is specifically designed for high-temperature and high-pressure working conditions, only allows seamless manufacturing, has stricter chemical composition control (especially restrictions on silicon, phosphorus, and sulfur), and has better high-temperature resistance and oxidation resistance. It is applicable to high-temperature and pressure systems such as boilers, heat exchangers, petrochemicals, etc. A53B is positioned for normal temperature and low pressure conveying or structural applications. It can be seamless or welded, and has a relatively low manufacturing cost. However, it is not suitable to replace A106B in high-temperature and high-pressure environments.

Summary

ASTM A106 Grade B has multiple equivalent standards worldwide. However, due to differences in chemical composition, mechanical properties and applications, careful evaluation must be conducted before substitution.

Read more : ASTM A106 schedule 40 dimensions