ASTM A106يعد أحد المعايير الأكثر استخدامًا للأنابيب الفولاذية الكربونية غير الملحومة ذات درجات الحرارة العالية في جميع أنحاء العالم ، ويتم تطبيقه على نطاق واسع في الغلايات ومحطات الطاقة والبتروكيماويات وصناعات تكرير النفط.

في المشتريات الدولية والمشاريع الهندسية ، غالبًا ما يواجه المهندسون والمشترون مثل هذا السؤال: ما الذي يتوافق مع ASTM A106 في المعايير الوطنية الأخرى ؟

توفر هذه المقالة جدول مقارنة قياسي مكافئ كامل ، يغطي معايير مثل ASME و API و EN و DIN و BS و JIS ، ويحلل الاختلافات في تركيبها الكيميائي وخواصها الميكانيكية لمساعدتك في إجراء الاستبدال والاختيار الصحيح.

مقدمة إلى ASTM A106

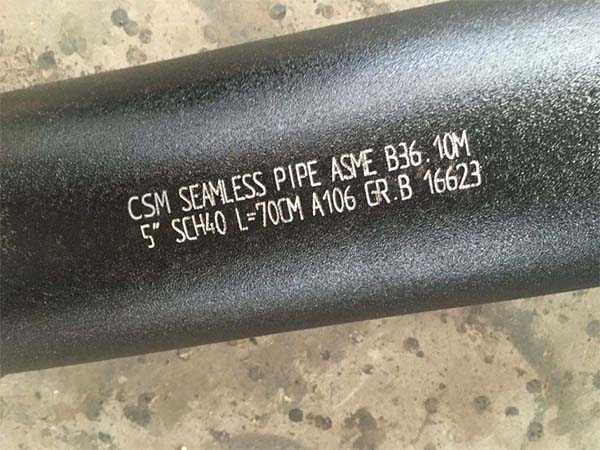

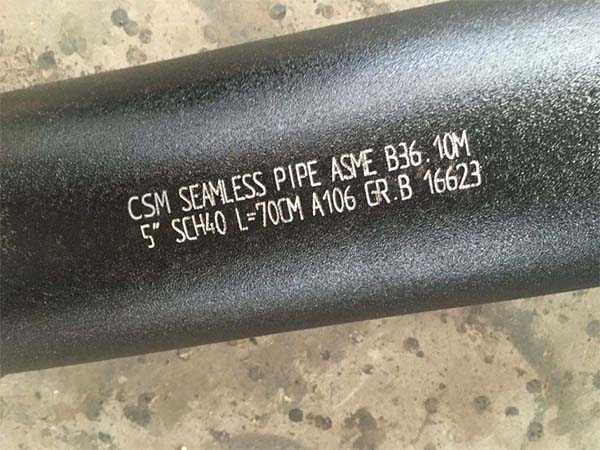

إن ASTM A106 قابل للتطبيق بشكل أساسي على أنابيب الصلب الكربوني غير الملحومة في ظروف العمل ذات درجة الحرارة العالية وينقسم إلى ثلاث درجات: الدرجة A ، الدرجة B ، والصف C. من بينها ، الدرجة B هي الأكثر شيوعًا في السوق.

التطبيقات الشائعة

أنبوب نقل عالي الحرارة

الغلاية والمبادل الحراري

خط أنابيب نظام توليد الطاقة

جدول مقارنة قياسي مكافئ

|

Standard

|

Grade

|

Chemical Composition (max %, unless noted)

|

Mechanical Properties

|

|

ASTM A106

|

Gr. B

|

C ≤ 0.30, Mn 0.29–1.06, P ≤ 0.035, S ≤ 0.035, Si ≥ 0.10

|

Tensile ≥ 415 MPa, Yield ≥ 240 MPa, Elong ≥ 30%

|

|

ASME SA106

|

Gr. B

|

Same as ASTM A106

|

Same as ASTM A106

|

|

API 5L

|

Grade B

|

C ≤ 0.28, Mn ≤ 1.20, P ≤ 0.030, S ≤ 0.030

|

Tensile ≥ 415 MPa, Yield ≥ 245 MPa

|

|

EN 10216-2

|

P265GH

|

C ≤ 0.20, Mn 0.80–1.40, P ≤ 0.025, S ≤ 0.015

|

Tensile 410–530 MPa, Yield ≥ 265 MPa

|

|

DIN 17175

|

St45.8

|

C ≤ 0.21, Mn 0.40–1.20, P ≤ 0.025, S ≤ 0.025

|

Tensile 410–530 MPa, Yield ≥ 255 MPa

|

|

BS 3059 Pt.2

|

360

|

C ≤ 0.23, Mn 0.40–1.06, P ≤ 0.040, S ≤ 0.040

|

Tensile 360–500 MPa, Yield ≥ 235 MPa

|

|

JIS G3454

|

STPG410

|

C ≤ 0.25, Mn 0.30–0.90, P ≤ 0.035, S ≤ 0.035

|

Tensile ≥ 410 MPa, Yield ≥ 245 MPa

|

Precautions

Although these standard performances are similar, they cannot be completely equated and interchanged, especially when used in pressure vessels or high-temperature working conditions, the chemical composition, mechanical properties and design specification requirements need to be rechecked.

If it is a boiler or heat exchanger project, it is recommended to directly use ASTM A106 GR.B or high-temperature standard steel pipes of equal strength.

Key analysis

1. Chemical composition differences

EN 10216-2 P265GH has a lower carbon content, stricter control over phosphorus and sulfur content, and better welding performance.

Although API 5L Grade B has similar strength, it is mainly used in conveying pipelines rather than high-temperature boilers.

2. Differences in mechanical properties

The yield strength of the European standard (EN/DIN) is generally higher than that of ASTM A106 Gr.B (240 MPa).

The tensile strength requirement of BS 3059 Pt.2 360 is lower and it is not suitable for high-pressure and high-temperature substitution.

3. Application Precautions

ASTM A106 or EN 10216-2 P265GH is recommended for high-temperature working conditions.

API 5L Grade B is optional for oil and gas pipelines.

The boiler tubes can be selected as DIN 17175 St45.8 or BS 3059.

How does ASTM A106 GR.B compare with ASTM A53 GR.B?

The strength levels of ASTM A106 Gr.B and ASTM A53 Gr.B are similar. However, A106 B is specifically designed for high-temperature and high-pressure working conditions, only allows seamless manufacturing, has stricter chemical composition control (especially restrictions on silicon, phosphorus, and sulfur), and has better high-temperature resistance and oxidation resistance. It is applicable to high-temperature and pressure systems such as boilers, heat exchangers, petrochemicals, etc. A53B is positioned for normal temperature and low pressure conveying or structural applications. It can be seamless or welded, and has a relatively low manufacturing cost. However, it is not suitable to replace A106B in high-temperature and high-pressure environments.

Summary

ASTM A106 Grade B has multiple equivalent standards worldwide. However, due to differences in chemical composition, mechanical properties and applications, careful evaluation must be conducted before substitution.

Read more : ASTM A106 schedule 40 dimensions